Method for preparing bionic bait having bright and stable color

A bionic bait and bright-coloured technology, which is applied in the field of bionic bait processing, can solve the problems of destroying the full biodegradability of polylactic acid, reducing the intensity of fish attraction, and affecting the effect of fishing, etc. Competitiveness and promotion and application value, the effect of color stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

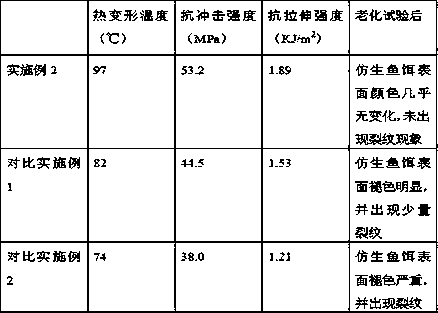

Examples

Embodiment 1

[0032] A preparation method of a brightly colored and stable bionic bait, comprising the steps of:

[0033] (1) Preparation of modified polylactic acid:

[0034] 1) Mix terephthalic acid and ethylene glycol into the reactor according to the molar ratio of 1:1.4, heat to keep the temperature in the reactor at 200°C, and keep stirring until the degree of esterification is more than 50%, and then add Put a composite filler with 8% of the total mass of the material in the reaction kettle, and continue to stir for treatment. When the degree of esterification is above 90%, add antimony trioxide catalyst, and raise the temperature in the reaction kettle to 290°C, and vacuumize at the same time. , take out the mixture after 2h for subsequent use;

[0035] 2) Put the mixture prepared in operation 1) into the extruder, extrude and granulate, and take out the modified polylactic acid after completion;

[0036] (2) Raw materials are weighed for backup:

[0037] Weigh the following raw ...

Embodiment 2

[0054] A preparation method of a brightly colored and stable bionic bait, comprising the steps of:

[0055] (1) Preparation of modified polylactic acid:

[0056] 1) Put terephthalic acid and ethylene glycol into the reactor according to the molar ratio of 1:1.6, heat to keep the temperature in the reactor at 220°C, and keep stirring until the degree of esterification exceeds 50%, and then add Put the composite filler with 10% of the total mass of the material in the reaction kettle, and continue to stir the treatment. When the degree of esterification is above 90%, add antimony trioxide catalyst, and raise the temperature in the reaction kettle to 310 ° C, and vacuumize at the same time , After 2.2h, take out the mixture for later use;

[0057] 2) Put the mixture prepared in operation 1) into the extruder, extrude and granulate, and take out the modified polylactic acid after completion;

[0058] (2) Raw materials are weighed for backup:

[0059] Weigh the following raw mat...

Embodiment 3

[0076] A preparation method of a brightly colored and stable bionic bait, comprising the steps of:

[0077] (1) Preparation of modified polylactic acid:

[0078] 1) Mix terephthalic acid and ethylene glycol into the reactor according to the molar ratio of 1:1.8, heat to keep the temperature in the reactor at 230°C, and keep stirring until the degree of esterification is more than 50%, and then add Put a composite filler with 12% of the total mass of the material in the reactor, and continue to stir until the esterification degree is above 90%, add antimony trioxide catalyst, and raise the temperature in the reactor to 320 ° C, and vacuumize at the same time , After 2.5h, take out the mixture for subsequent use;

[0079] 2) Put the mixture prepared in operation 1) into the extruder, extrude and granulate, and take out the modified polylactic acid after completion;

[0080] (2) Raw materials are weighed for backup:

[0081] Weigh the following raw materials in corresponding p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com