Air source heat pump water heating device regional staged heat preserving integrated machine

An air source heat pump and water heater technology, applied in the direction of heat storage heater, fluid heater, climate sustainability, etc., can solve the problems of high energy consumption, low performance coefficient of heat pump system, low energy utilization rate, etc., and achieve heat release Temperature balance, compact structure, and obvious energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

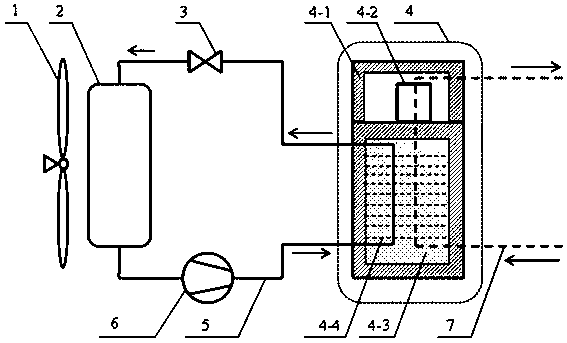

[0035] An air source heat pump water heater with cascaded heat storage integrated machine in different regions, its structure is as follows: figure 1 As shown, it includes an outdoor fan 1, and also includes an evaporator 2, a compressor 6, a condenser / heat storage integrated device 4, and a throttling device 3 that are sequentially connected and constitute a circulation loop, wherein the condenser / heat storage is integrated The heating device 4 has dual functions of a refrigerant condenser and sub-regional cascaded heat storage, including two parts of a medium-temperature cavity and a high-temperature cavity, wherein the medium-temperature cavity is provided with two sets of staggered heat exchange coils, one of which is To connect the compressor 6 and the refrigerant coil 5 of the throttling device 3 respectively, the other group is the hot water coil 7 for heating, the medium temperature cavity is also filled with phase change materials 4-3, and the high temperature cavity i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com