Air source heat pump system with functions of large-temperature-difference graded heat storage and graded heat use

An air source heat pump and large temperature difference technology, which is applied in heating systems, heat pumps, space heating and ventilation, etc., can solve the problems of oil loss, abnormal operation of exhaust temperature, insufficient heating capacity, etc., and increase heat storage density , simple structure, and the effect of improving the energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

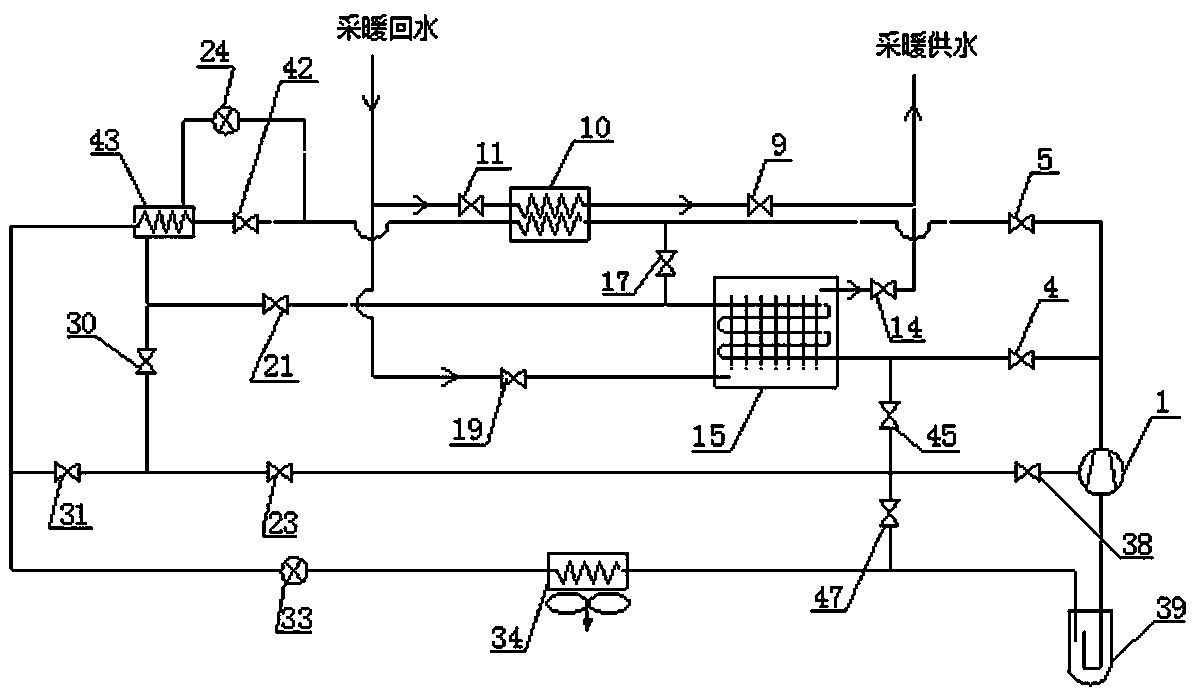

[0033] refer to figure 1 , image 3 with Figure 4 , an air source heat pump system with large temperature difference for staged heat storage and staged heat consumption, including an air injection enthalpy increasing compressor 1, a condenser 10, a first throttle valve 24, a second throttle valve 33, an economizer 43, an air-cooled Evaporator 34, gas-liquid separator 39, high temperature hot water storage tank 15, first solenoid valve 4, second solenoid valve 5, third solenoid valve 17, fourth solenoid valve 21, fifth solenoid valve 23, sixth solenoid valve Valve 30, seventh solenoid valve 31, ninth solenoid valve 38, tenth solenoid valve 42, eleventh solenoid valve 45, twelfth solenoid valve 47, first water valve 9, second water valve 11, third water valve Valve 14, the fourth water valve 19, the condenser 10 includes a refrigerant channel and a hot water channel for heat exchange, the economizer 43 includes a cooling coil and there are liquid and gas refrigerants, and the...

Embodiment 2

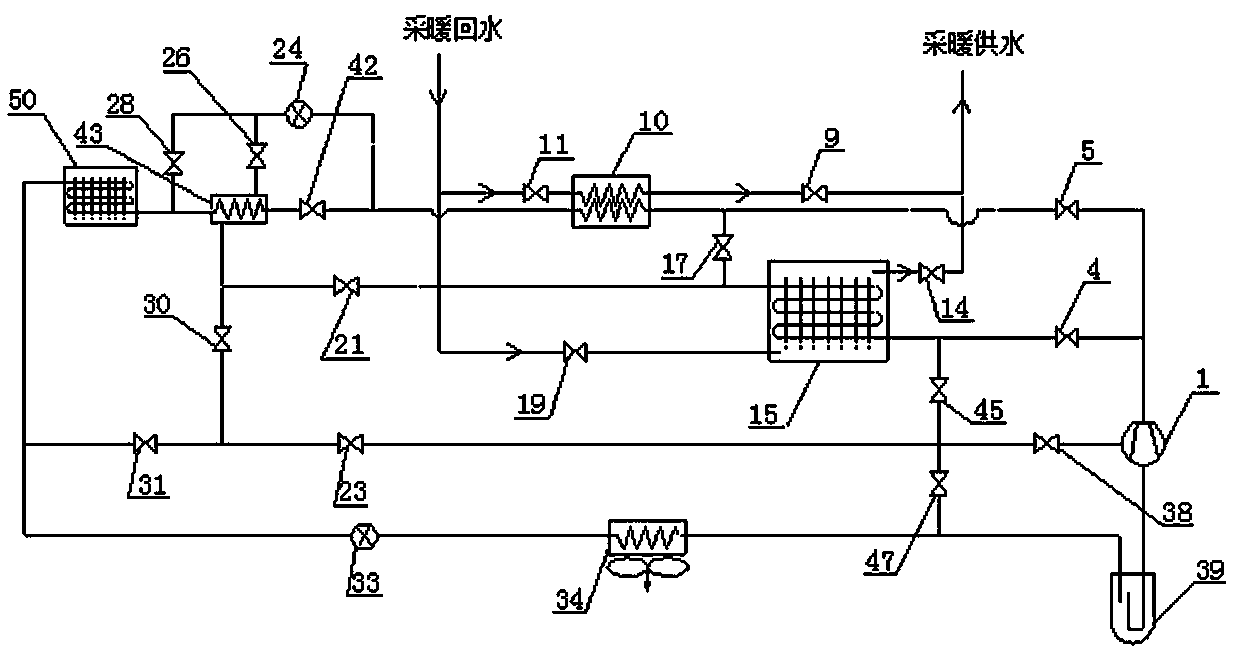

[0046] refer to figure 2 , image 3 , Figure 4 and Figure 5 , on the basis of Embodiment 1, this embodiment also includes a low-temperature heat storage tank (50), a thirteenth solenoid valve (26), and a fourteenth solenoid valve (28), and the low-temperature heat storage tank (50) includes fins The finned tube (50a) and the shell (50b), the finned tube (50a) is composed of vertical fins and horizontal serpentine coils, the horizontal serpentine coils are provided with refrigerant inlets and outlets, and the shell (50b) Set outside the finned tube (50a) and seal it, wrap the finned tube (50a) inside, the gap between the finned tube (50a) and the shell (50b) is filled with low-temperature hot water, the first electronic expansion valve (24) The outlet port of the thirteenth solenoid valve (26) and the inlet port of the fourteenth solenoid valve (28) are connected at the same time, and the outlet port of the thirteenth solenoid valve (26) is connected with the liquid state...

Embodiment 3

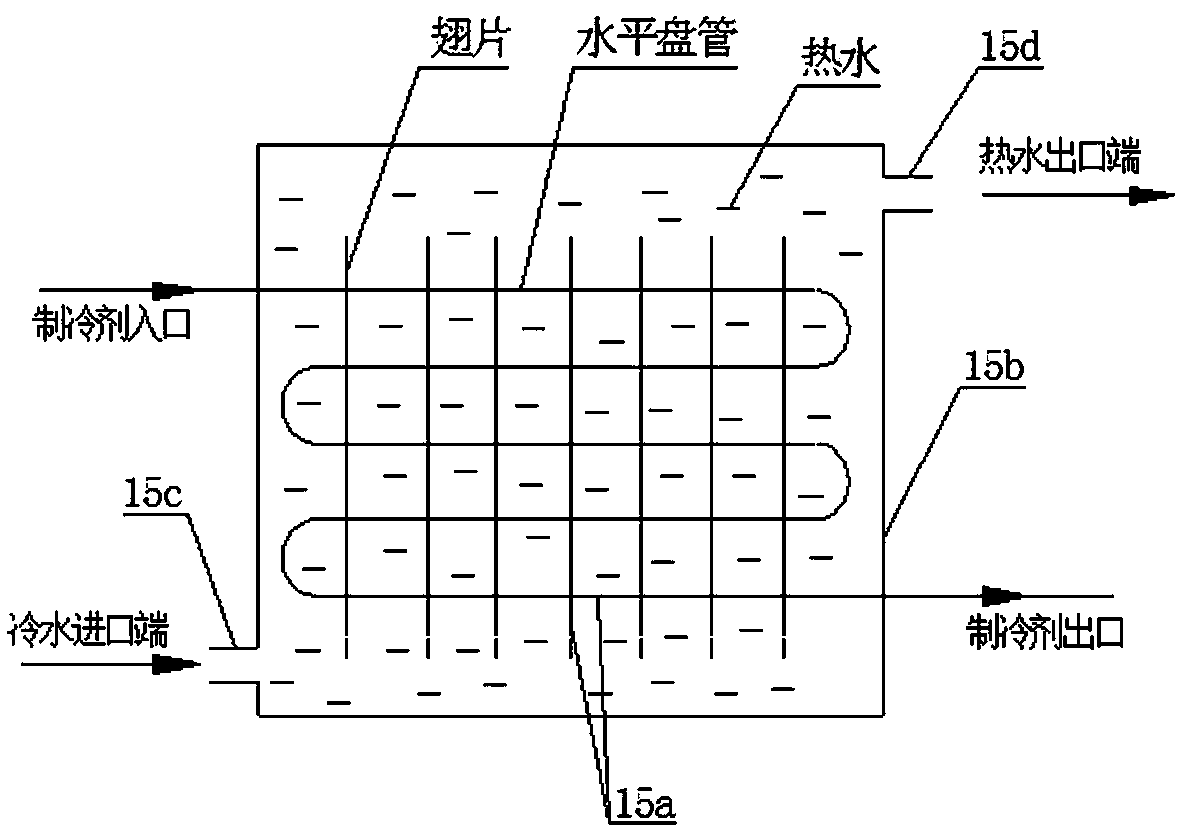

[0059] refer to image 3 , the high-temperature heat storage tank 15 includes a finned tube 15a, a shell 15b, a hot water inlet 15c and a hot water outlet 15d, wherein the finned tube 15a is composed of vertical fins and horizontal serpentine coils, and the horizontal serpentine The coil is provided with the inlet and outlet of the refrigerant, and the shell 15b is arranged on the outside of the finned tube 15a and sealed to wrap the finned tube 15a inside. The upper and lower surfaces of the finned tube 15a are not in contact with the shell 15b, leaving a certain distance. The gap between the finned tube 15a and the shell 15b is filled with water. It is arranged on the uppermost part of the side of the shell 15b. When cold water enters the hot water storage tank from the hot water inlet port 15c, the corresponding hot water in the upper part of the hot water storage tank will flow out from the hot water outlet port 15d. The high-temperature hot water storage tank 15 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com