Multi-parameter adjustable spray flow experimental system

An experimental system and multi-parameter technology, applied in the field of mist flow experimental system, can solve the problems of poor adaptability of the correction model, easy deposition of droplets, and difficulties in adjusting and controlling flow parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

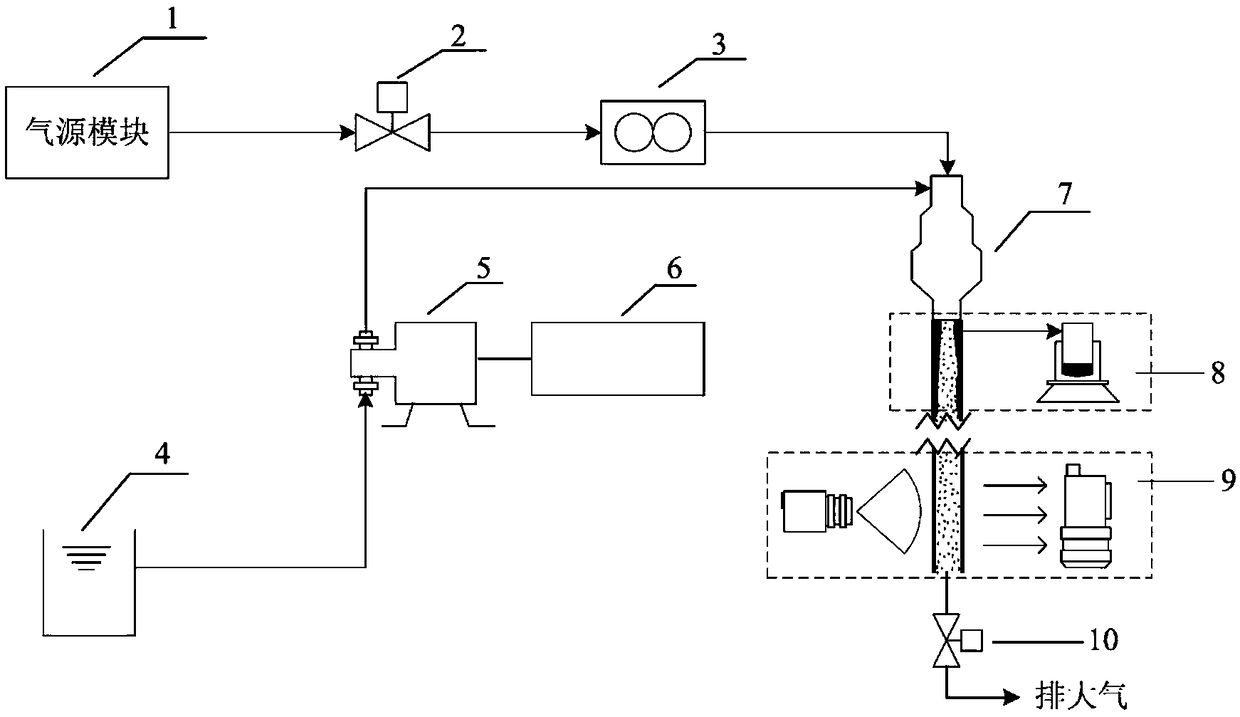

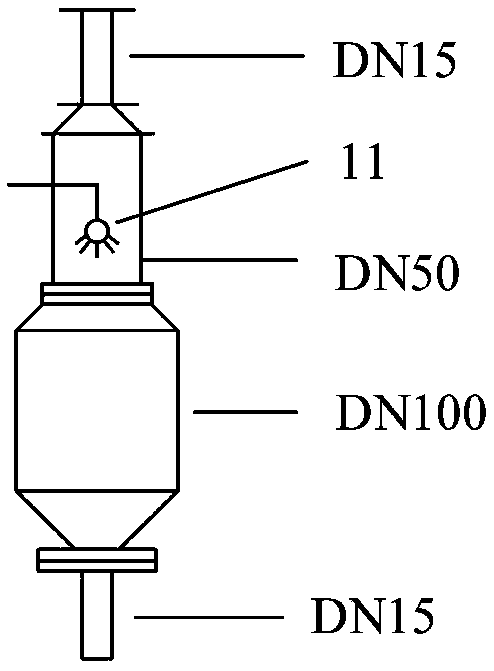

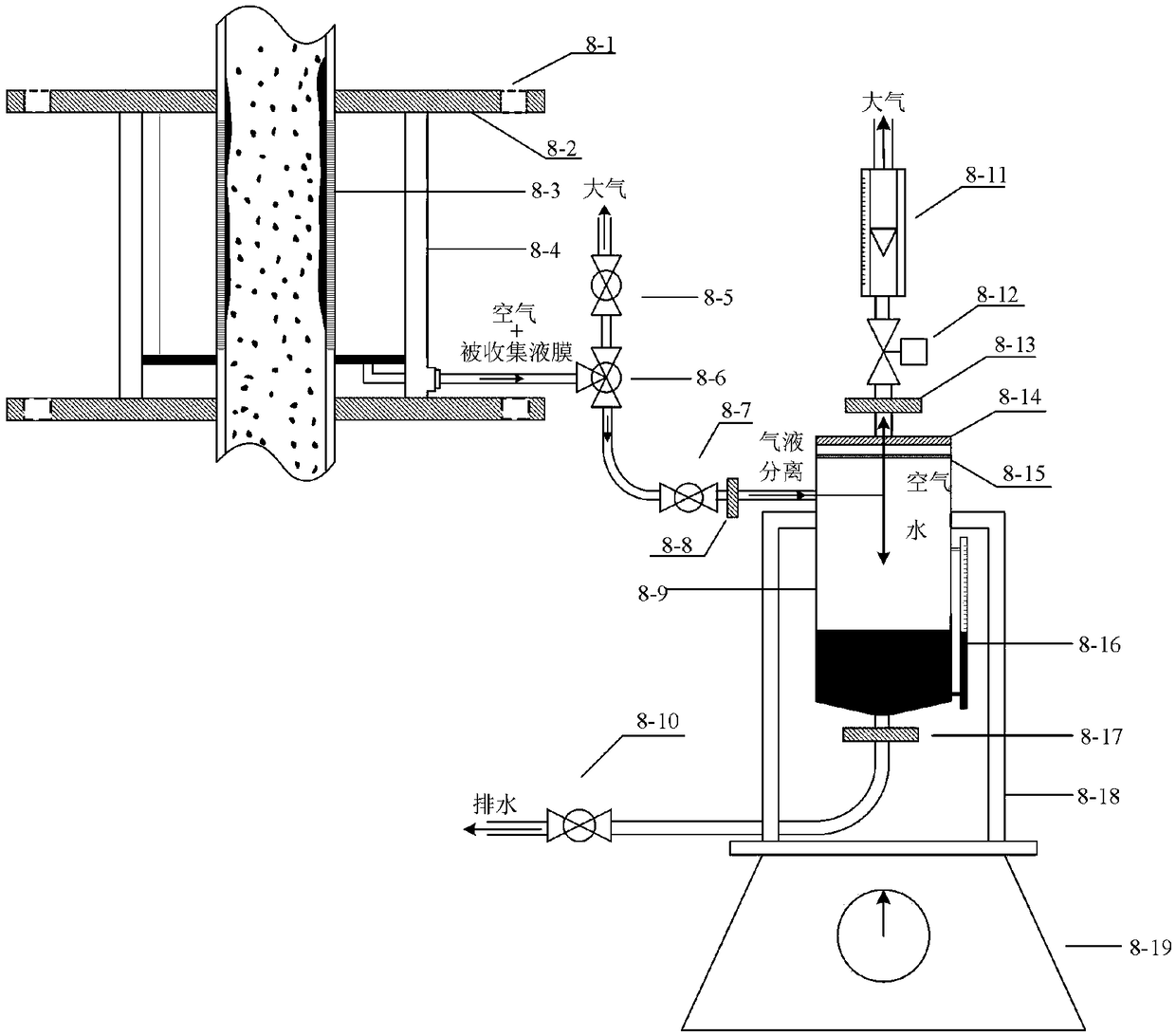

[0034] The structural diagram of the mist flow experiment system with adjustable multi-parameters of the present invention can be found in figure 1 , mainly including air source module 1, flow regulating valve 2, vortex flowmeter 3, water storage tank 4, metering pump 5, frequency converter 6, atomization mixing section 7, liquid film collection device 8, extinction method particle measuring instrument 9 , Throttle valve 10, etc. The air is provided by the air source module 1, the air flow and pressure are controlled by the combination of the flow regulating valve 2 and the throttle valve 10, and the flow regulating range is 5-25m 3 / h, pressure adjustment range 0.1 ~ 0.7MPa. The flow rate of the gas phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com