Multi-channel abrasive particle detecting method and device based on time division multiplexing technology

A time-division multiplexing and detection method technology, which is applied in the direction of measuring devices, particle size analysis, and analytical materials, can solve the problems of inconsistent sensitivity of multiple sensors, achieve the effect of low price and reduce the amount of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

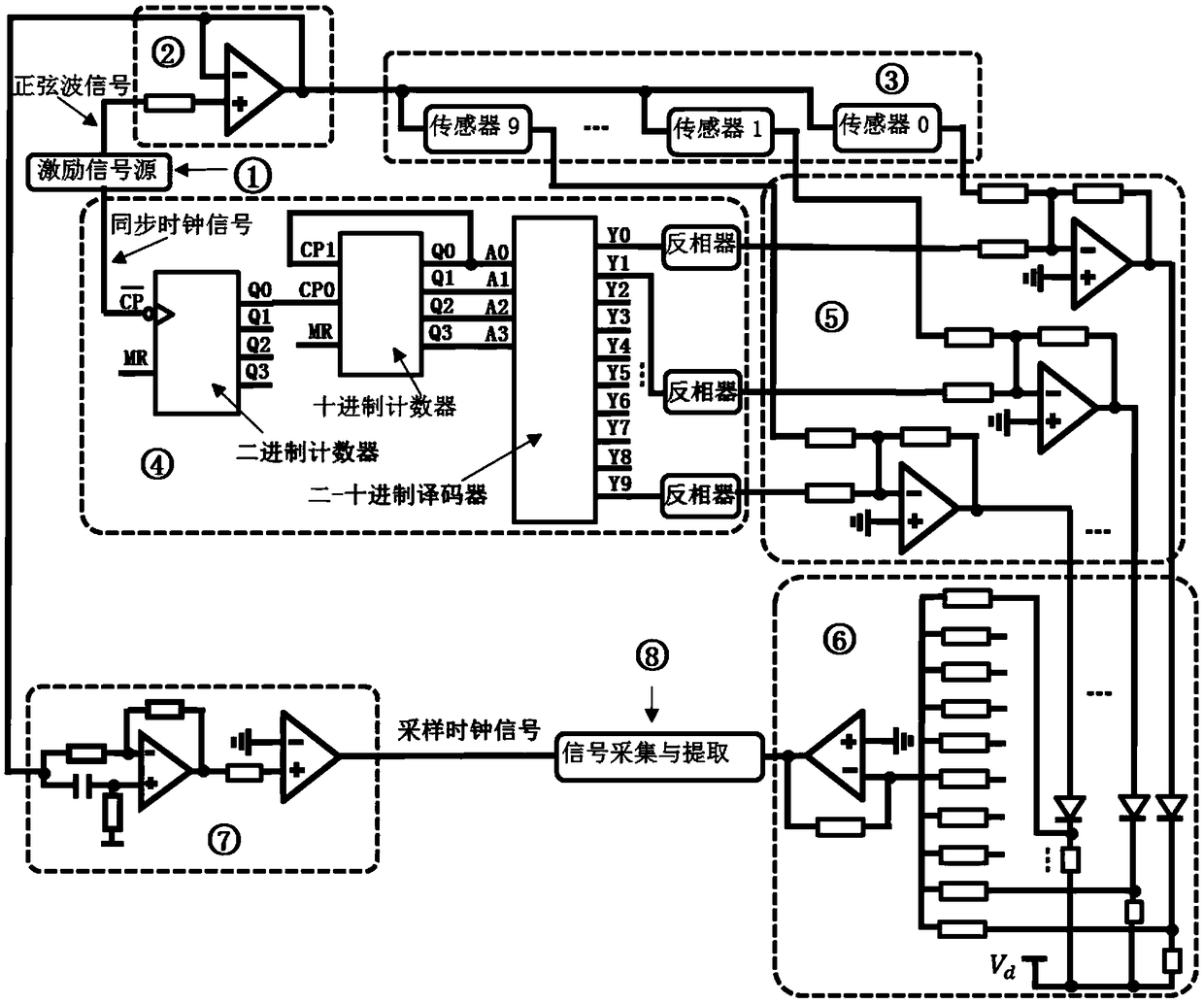

[0067] In this embodiment, a 10-channel wear particle detection sensor is taken as an example to illustrate a multi-channel oil wear particle detection method and device based on time division multiplexing technology of the present invention.

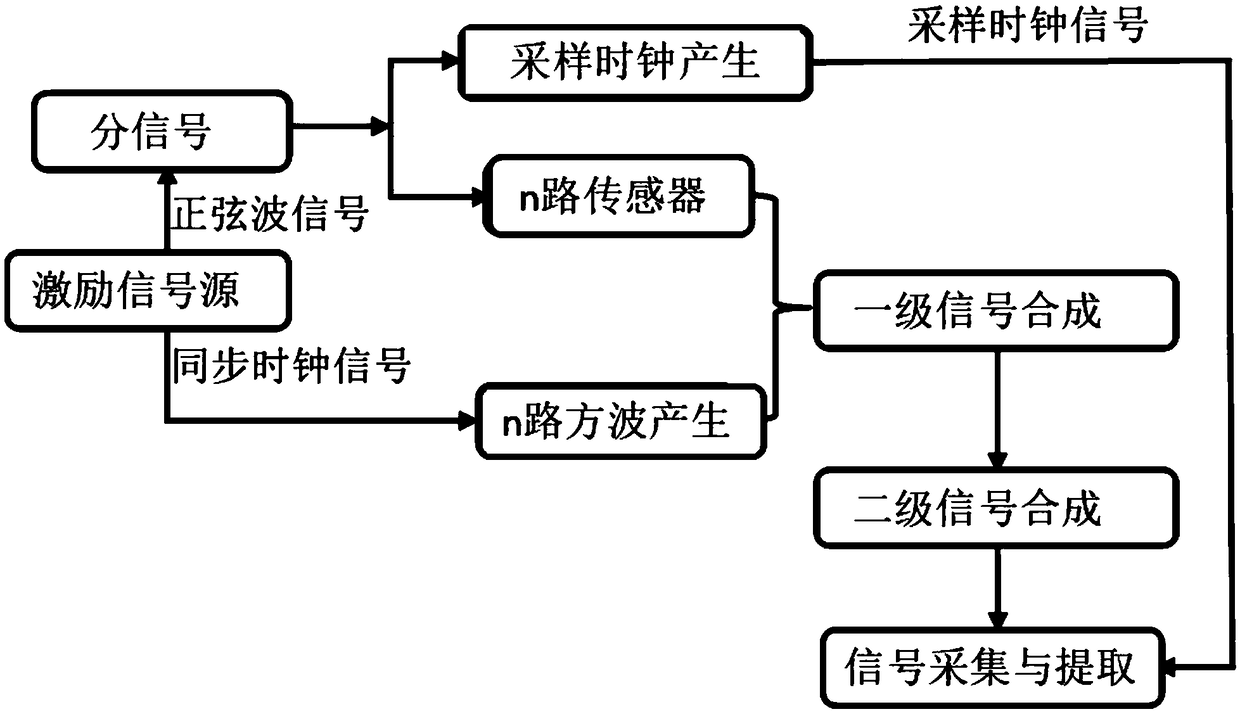

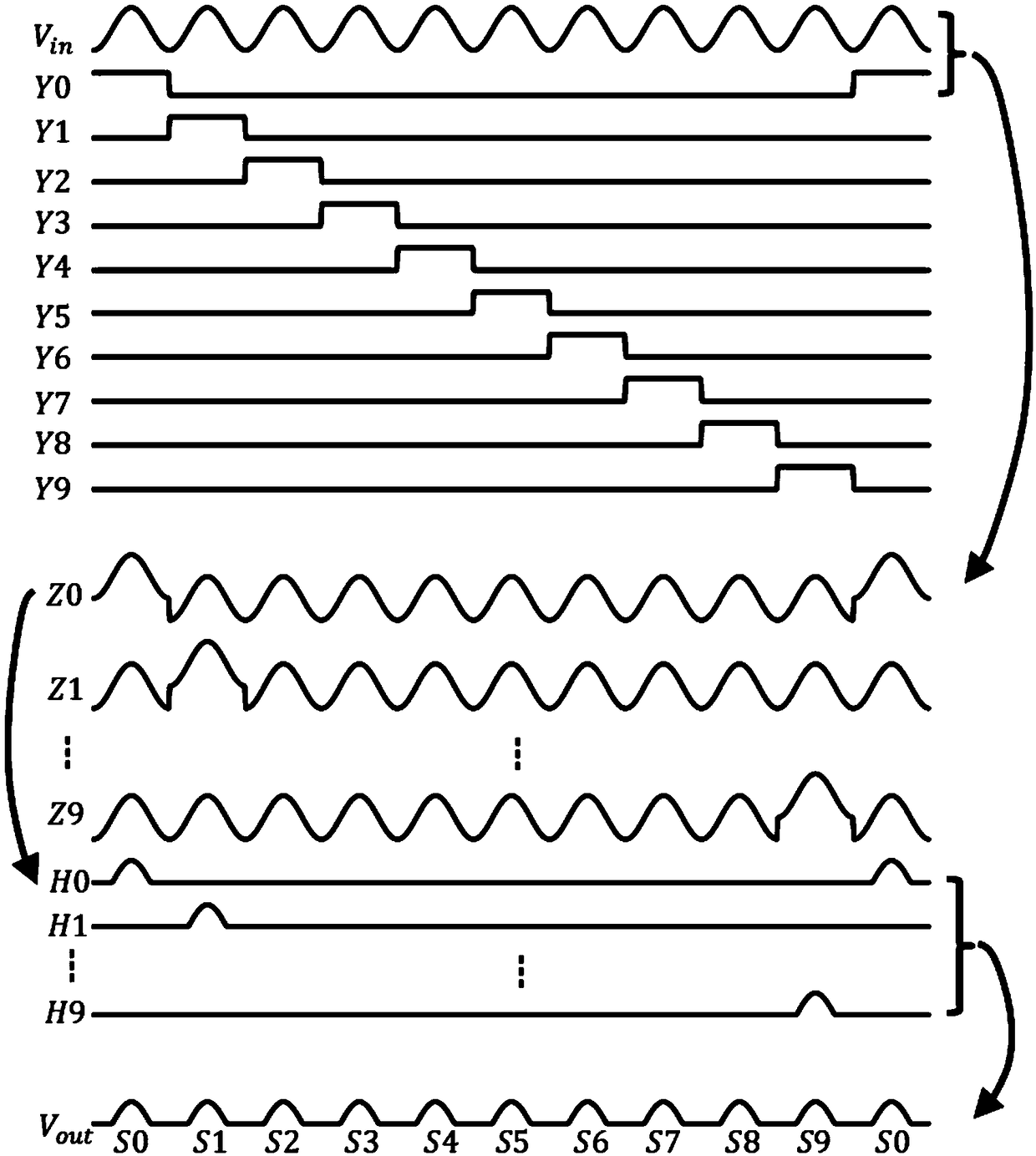

[0068] Such as figure 1 and figure 2 As shown, a multi-channel oil wear particle detection method based on time-division multiplexing technology, based on the principle of time-division multiplexing, makes multiple sensors work in different time periods, that is, the detection process of multiple sensors is staggered in time. In order to detect multiple sensor signals with only one signal acquisition channel, we intercept the peak values of the sine wave signals of multiple sensors and synthesize them into one output signal. The specific operation steps are as follows:

[0069] (1) sub-signal

[0070] In order to be able to detect the peak variation of the 10-way sine wave, the same sine wave signal V in Divided into 11 channels o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com