Method for predicting solidification microstructure of electroslag remelting ingot

A technology of microstructure and prediction method, applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of difficult to meet the requirements of process optimization and solidification structure control, poor transferability of mathematical models, difficulties in secondary development, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0119] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0120] In this embodiment, the rotor steel 30Cr1Mo1V process produced by electroslag remelting in a special steel plant is taken as an example, and the microstructure of the ingot solidified in the electroslag remelting process is analyzed by using the method for predicting the solidification microstructure of the electroslag remelting ingot of the present invention. Make predictions.

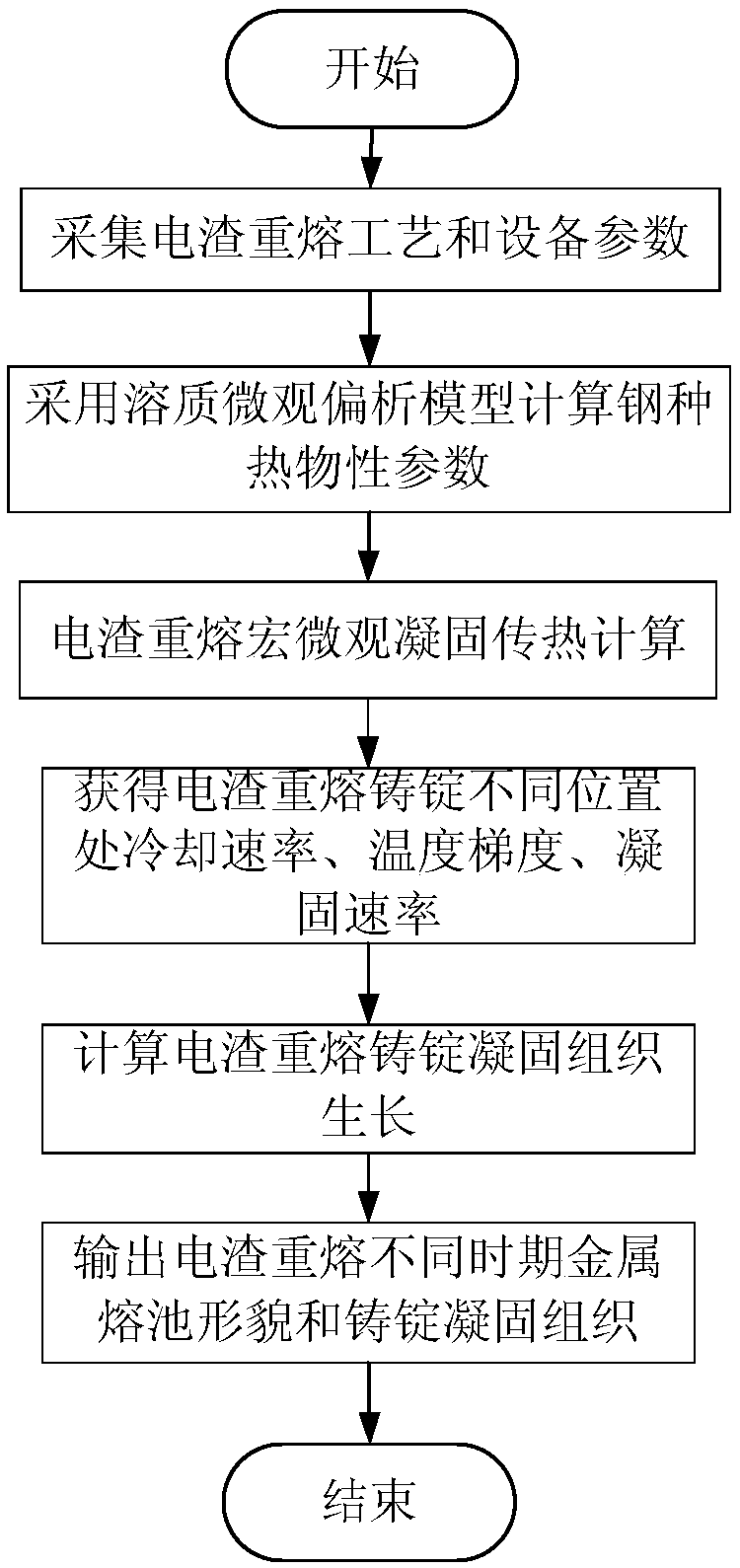

[0121] A method for predicting the solidification microstructure of electroslag remelting ingots, such as figure 1 shown, including the following steps:

[0122] Step 1, collecting equipment parameters and process parameters of electroslag remelting;

[0123] Equipment parameters include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com