Hydraulically built well cellar transplantation method and special well cellar builder thereof

A technology for well cellar transplanting and device making, which is applied in the fields of tobacco cultivation, etc. It can solve the problems of limiting the large-scale promotion of well cellar transplanting, extremely high requirements on soil moisture conditions, high maintenance and labor costs, and achieves the reduction of tobacco plants. The probability of disease occurrence, the benefit of contact, and the obvious effect of reducing labor and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment one: water making method well cellar transplanting method, comprise transplanting on the film, concrete steps are as follows:

[0032] Step 1. Ridging: During the period from late March to early April, according to the soil moisture and climate characteristics, the ridges should be raised early. The ridge spacing is 110-120 cm, the ridge height is 25-30 cm, the optimal ridge height is 30 cm, and the ridge bottom width is 70-80 cm. ; Apply basal fertilizer at the same time as ridging, the amount of pure nitrogen in basal fertilizer is 7.5-15kg / hm2 less than that of traditional transplanted tobacco fields, and the technical measures of fertilization are in accordance with "Guidelines for the Use of Flue-cured Tobacco Fertilizers" (YC / Z 459), "Tobacco Soil Testing Formula The provisions of the Fertilization Work Regulations (YC / T 507) shall be implemented; after the ridges are ridged, the ridges shall be straight and evenly lined, the ridges shall be full, the so...

Embodiment 2

[0043] Embodiment two: water making method well cellar transplanting method, comprise transplanting under film, concrete steps are as follows:

[0044] Step 1, ridging: same as embodiment one;

[0045] Step 2, making cellars:

[0046] a. 1-2 days before transplanting, mark the smoke ridge at a distance of 45-50 cm, and it is required to be clearly visible;

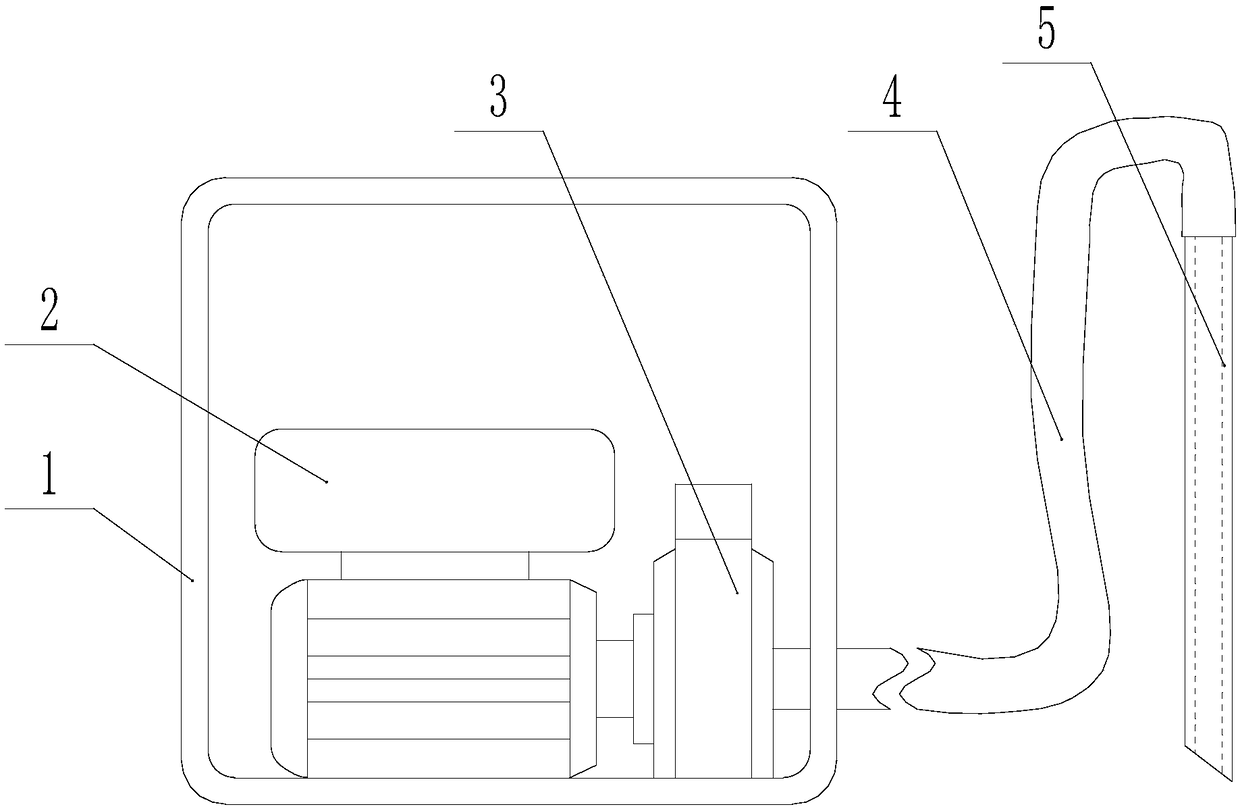

[0047]b. Use the well pit maker to insert the smoke ridge according to the marked points, and use the pressure of the water flow to make the well pit. The seedling fertilizer can be melted in the water, and the concentration of the seedling fertilizer is 1-1.5%, and 2-3kg of water is injected into each well pit. Make the mouth of the well pits made round, with a diameter of 6-8cm, a depth of 15-18cm, and a distance of 45-50cm between the wells, so as to ensure that the transplanting density reaches 18,000 plants / hm 2 above;

[0048] Step 3, transplanting: same as embodiment one;

[0049] Step 4, pest control: same as e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com