Blending-type purple potato essence and preparation method thereof

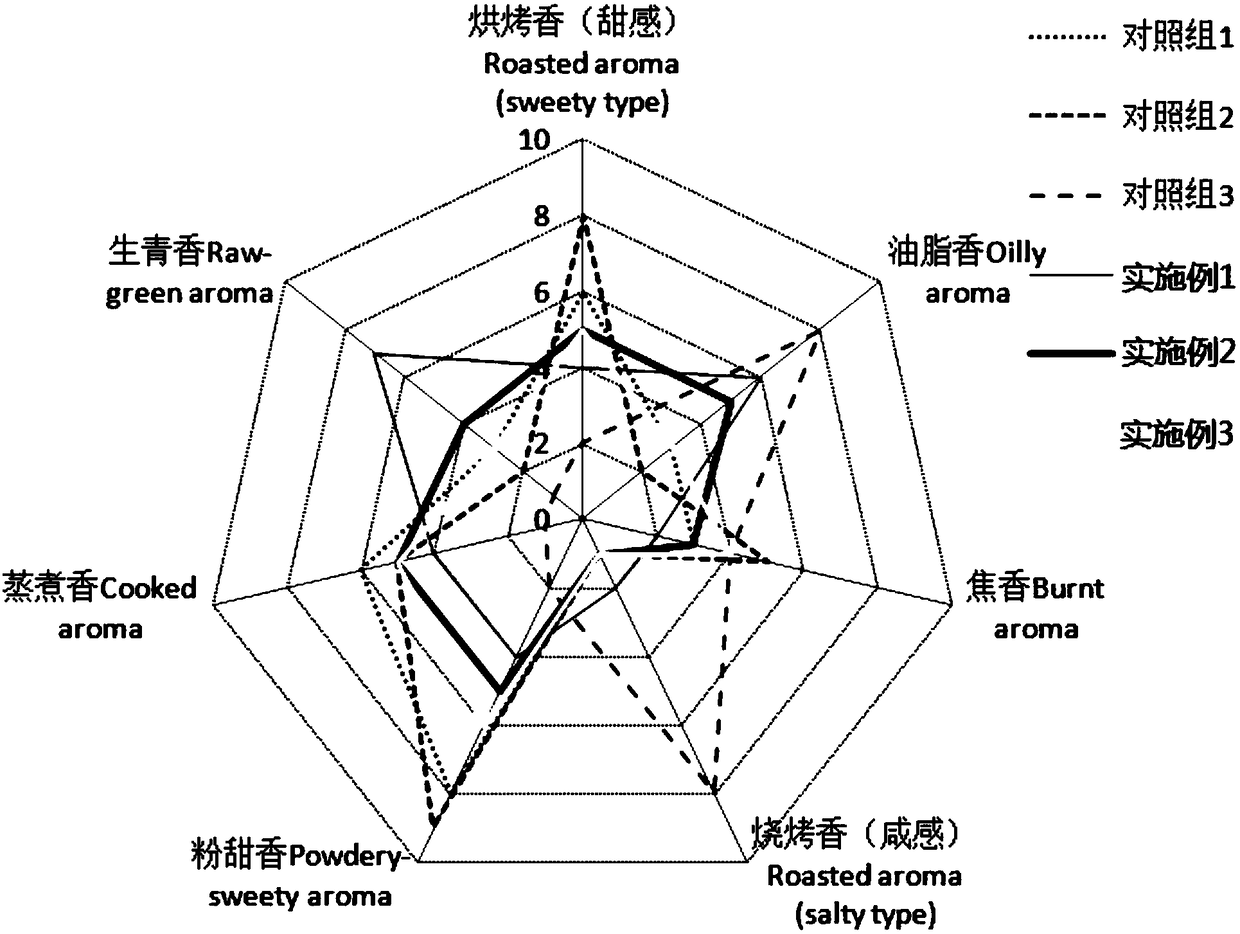

A purple potato and blending technology, applied in the field of flavors, can solve the problems of large aroma loss, short duration, and inability to continuously provide the sensory flavor of purple potatoes, etc., to achieve the effect of strengthening recognition, smelling sweet, and stimulating the desire to buy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

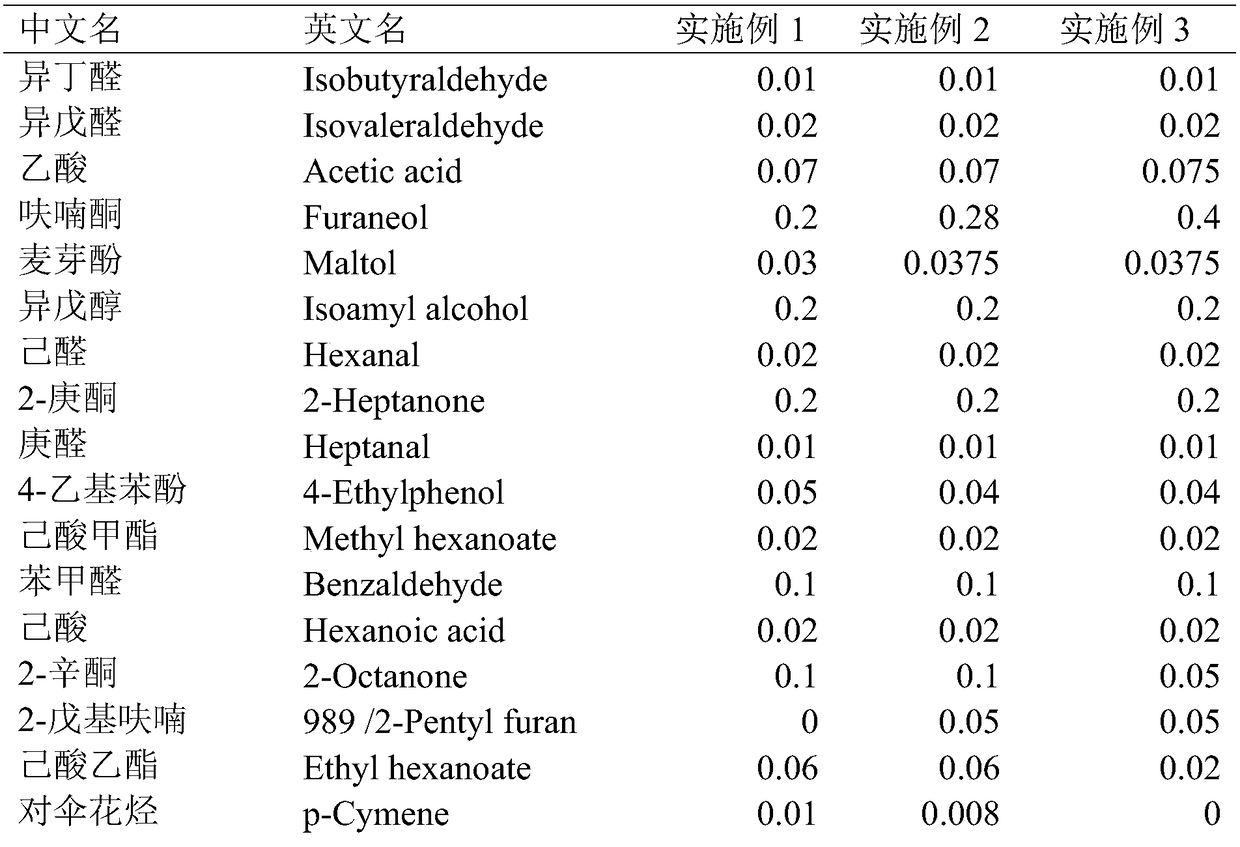

Embodiment 1

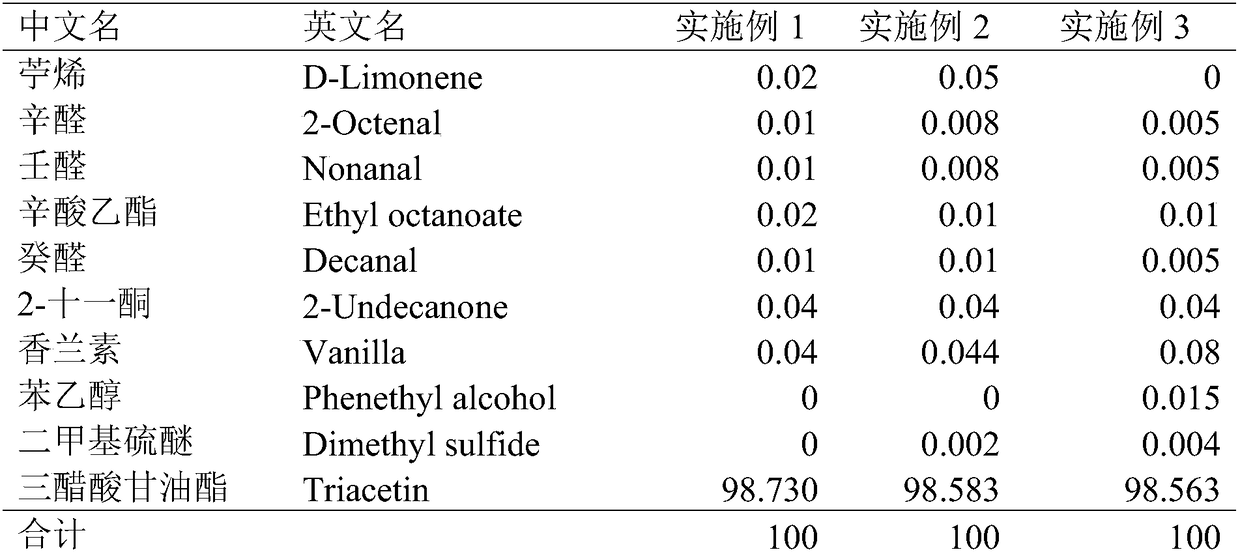

[0028] A blended purple potato flavor, comprising the following raw materials in parts by weight: 0.01 parts of isobutyraldehyde, 0.02 parts of isovaleraldehyde, 0.07 parts of acetic acid, 0.2 parts of furanone, 0.03 parts of maltol, 0.2 parts of isoamyl alcohol, and hexanal 0.02 parts, 2-heptanone 0.2 parts, heptanaldehyde 0.01 parts, 4-ethylphenol 0.05 parts, methyl caproate 0.02 parts, benzaldehyde 0.1 part, caproic acid 0.02 parts, 2-octanone 0.1 part, ethyl hexanoate 0.06 part of ester, 0.01 part of p-cymene, 0.02 part of limonene, 0.01 part of caprylic aldehyde, 0.01 part of nonanal, 0.02 part of ethyl caprylate, 0.01 part of decanal, 0.04 part of 2-undecone, 0.04 part of vanillin ; Liquid excipients (parts by weight): 98.73 parts of triacetin.

[0029] After the above raw materials and auxiliary materials are uniformly mixed and stirred, a blended purple potato flavor product can be prepared.

Embodiment 2

[0031] A blended purple potato flavor, comprising the following raw materials in parts by weight: 0.01 parts of isobutyraldehyde, 0.02 parts of isovaleraldehyde, 0.07 parts of acetic acid, 0.28 parts of furanone, 0.0375 parts of maltol, 0.2 parts of isoamyl alcohol, and hexanal 0.02 parts, 2-heptanone 0.2 parts, heptanal 0.01 parts, 4-ethylphenol 0.04 parts, methyl caproate 0.02 parts, benzaldehyde 0.1 parts, hexanoic acid 0.02 parts, 2-octanone 0.1 parts, 2-pentanone 0.05 parts of methyl furan, 0.06 parts of ethyl caproate, 0.008 parts of p-cymene; 0.05 parts of limonene, 0.008 parts of octanal, 0.008 parts of nonanal, 0.01 parts of ethyl caprylate, 0.01 parts of decanal, 0.04 parts of 2-undecone Parts, 0.044 parts of vanillin, 0.002 parts of dimethyl sulfide; liquid auxiliary material (parts by weight): 98.5825 parts of triacetin.

[0032] After the above raw materials and auxiliary materials are uniformly mixed and stirred, a blended purple potato flavor product can be prepare...

Embodiment 3

[0034] A blended purple potato flavor, comprising the following raw materials in parts by weight: 0.01 parts of isobutyraldehyde, 0.02 parts of isovaleraldehyde, 0.075 parts of acetic acid, 0.4 parts of furanone, 0.0375 parts of maltol, 0.2 parts of isoamyl alcohol, and hexanal 0.02 parts, 2-heptanone 0.2 parts, heptanal 0.01 parts, 4-ethylphenol 0.04 parts, methyl caproate 0.02 parts, benzaldehyde 0.1 parts, hexanoic acid 0.02 parts, 2-octanone 0.05 parts, 2-pentanone 0.05 parts of methyl furan, 0.02 parts of ethyl caproate, 0.005 parts of caprylic aldehyde, 0.005 parts of nonanal, 0.01 parts of ethyl octanoate, 0.005 parts of decanal, 0.04 parts of 2-undecone, 0.08 parts of vanillin, 0.015 parts of phenethyl alcohol , 0.004 parts of dimethyl sulfide; liquid auxiliary materials (parts by weight): 98.5635 parts of triacetin.

[0035] After the above raw materials and auxiliary materials are uniformly mixed and stirred, a blended purple potato flavor product can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com