Volatile oil crystal extraction system and essential oil production assembly line

An extraction system and volatile oil technology, which is applied in solution crystallization, essential oil/fragrance, heat exchange cooling crystallization, etc., can solve the problem of insufficient extraction rate of volatile oil, achieve simple and convenient operation, high separation efficiency, and save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

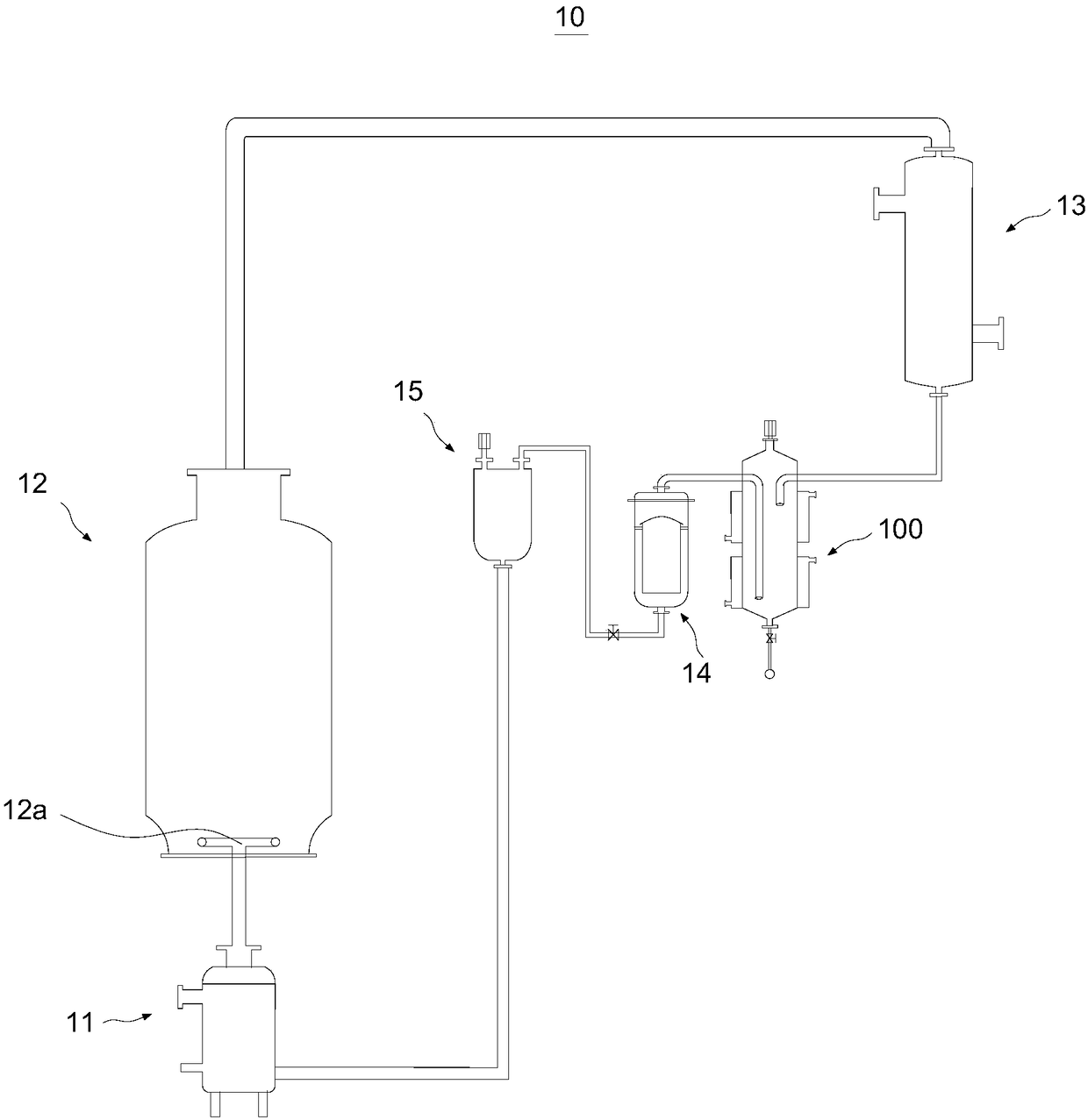

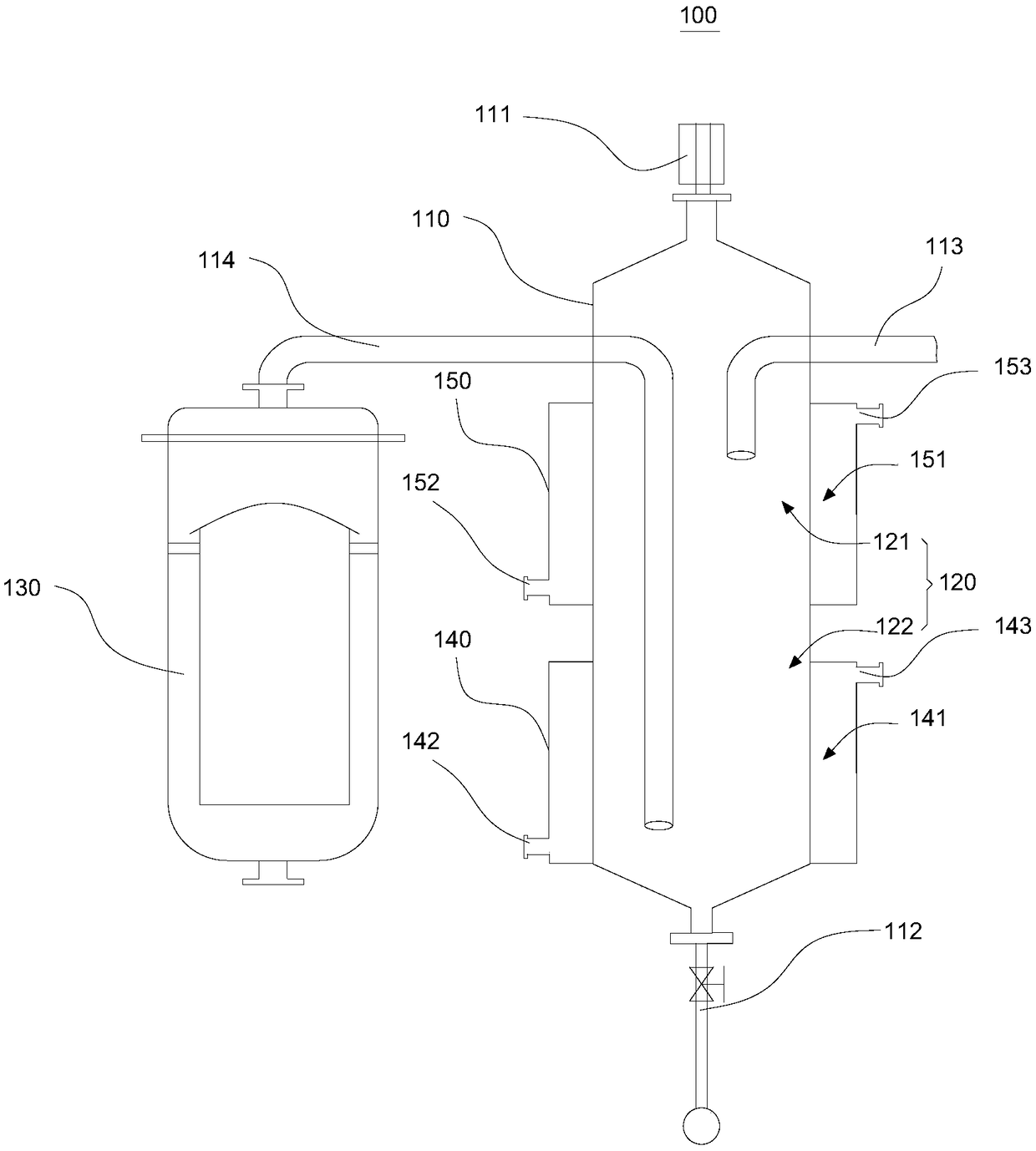

[0038] The present embodiment provides a kind of volatile oil crystallization extraction system 10, refer to figure 1 As shown, it includes a steam generator 11 , an extraction tank 12 , a condenser 13 , a filtering device 14 and a variable temperature crystallization oil-water separator 100 . Wherein, the steam generator 11 is communicated with the steam inlet at the bottom of the extraction tank 12, the gas phase outlet at the top of the extraction tank 12 is communicated with the feed end of the condenser 13, and the discharge end of the condenser 13 is communicated with the feed of the variable temperature crystallization oil-water separator 100. The discharge end of the variable temperature crystallization oil-water separator 100 passes through the filter device 14 and communicates with the steam generator 11. The bottom of the extraction tank 12 is provided with a steam distributor 12a for evenly distributing the steam that the steam generator 11 passes into the extracti...

no. 2 example

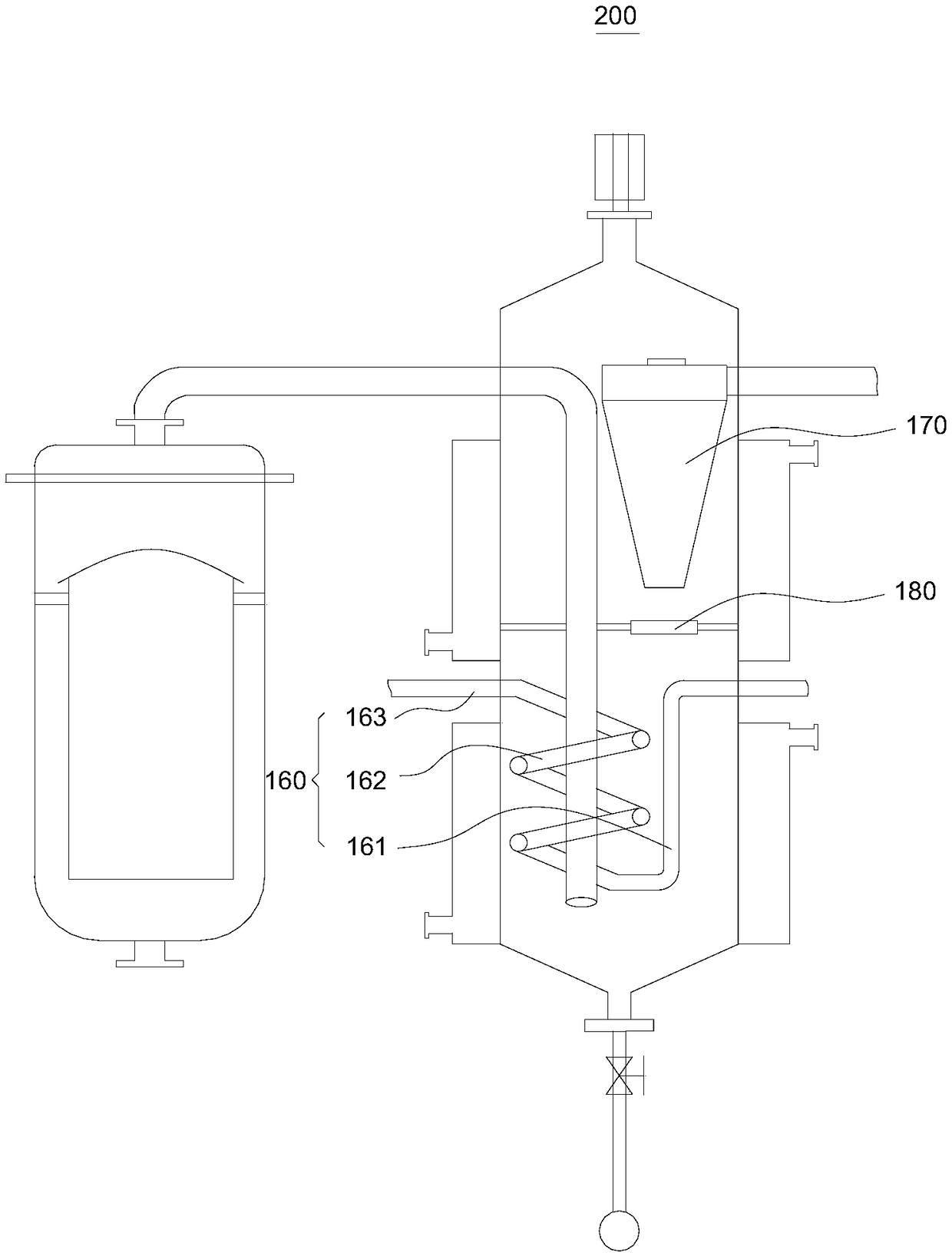

[0050] This embodiment provides a volatile oil crystallization extraction system (not shown in the figure), which differs from the variable temperature crystallization oil-water separator 100 provided in the first embodiment in that it uses a variable temperature crystallization oil-water separator 200 . The temperature-variable crystallization oil-water separator 200 is improved on the basis of the variable-temperature crystallization oil-water separator 100, and its difference from the variable-temperature crystallization oil-water separator 100 is as follows.

[0051] In order to further improve the cooling efficiency, such as image 3 As shown, the variable temperature crystallization oil-water separator 200 in this embodiment is also provided with a condensation pipe 160, the condensation pipe 160 includes a liquid inlet pipe 161, a spiral pipe 162 and a liquid outlet pipe 163, and the spiral pipe 162 is located in the second separation chamber 122, And set around the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com