Solid-gas microchannel reactor

A microchannel reactor and microchannel technology, applied in chemical/physical/physical chemical reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve the problems affecting the contact between gas and microchannel reactor, micro Dirty channel reactors, affecting catalytic efficiency and other issues, to achieve the effect of ensuring contact efficiency, good buffering effect, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

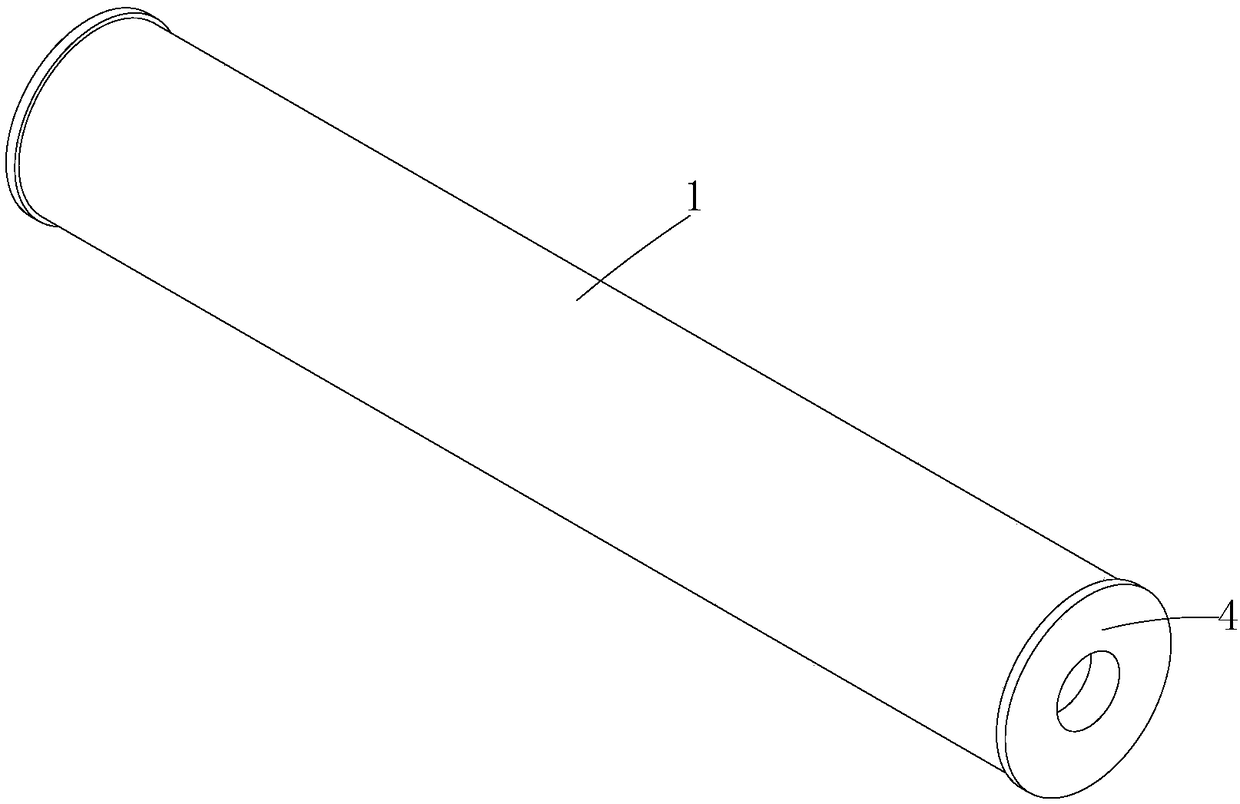

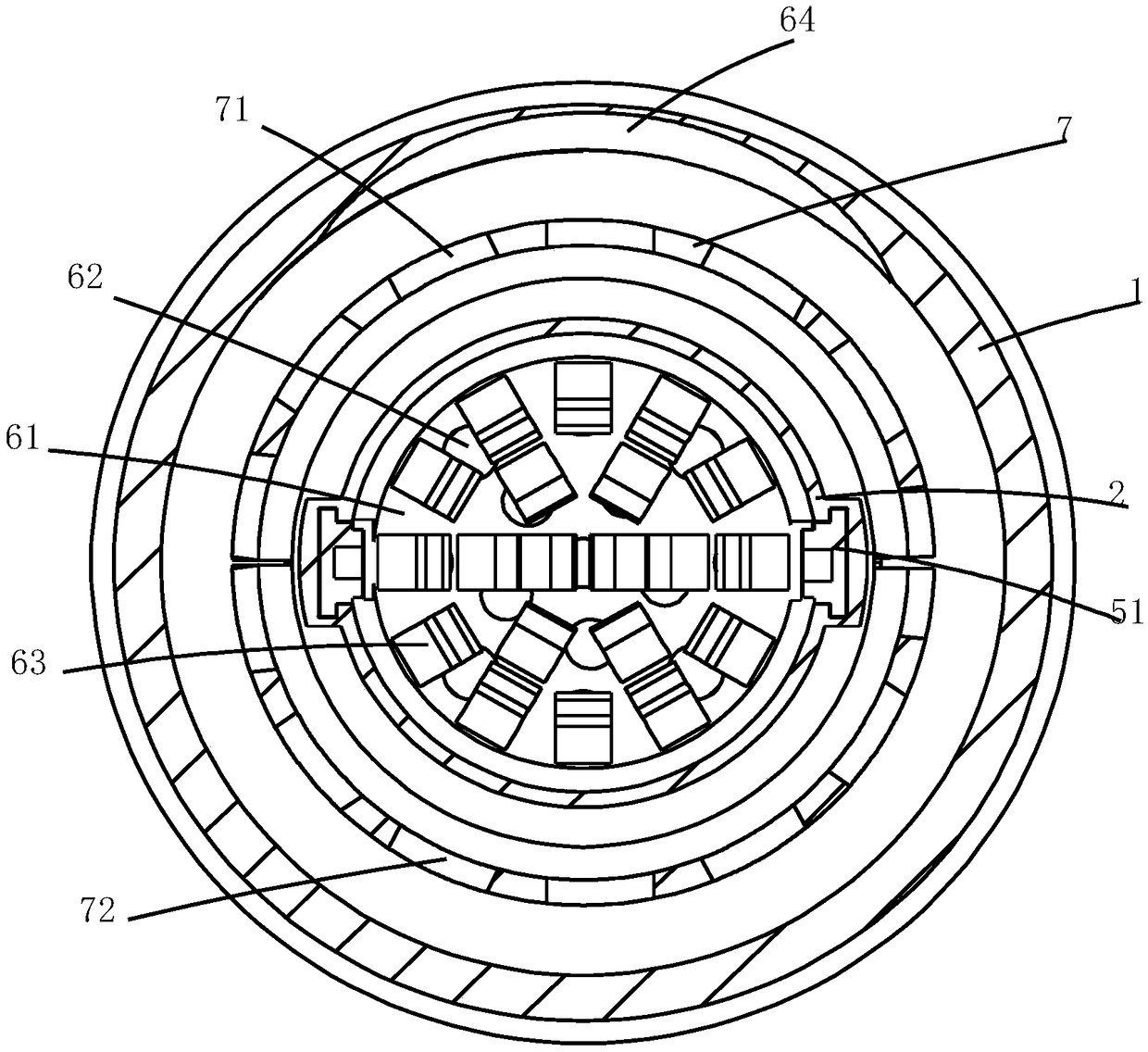

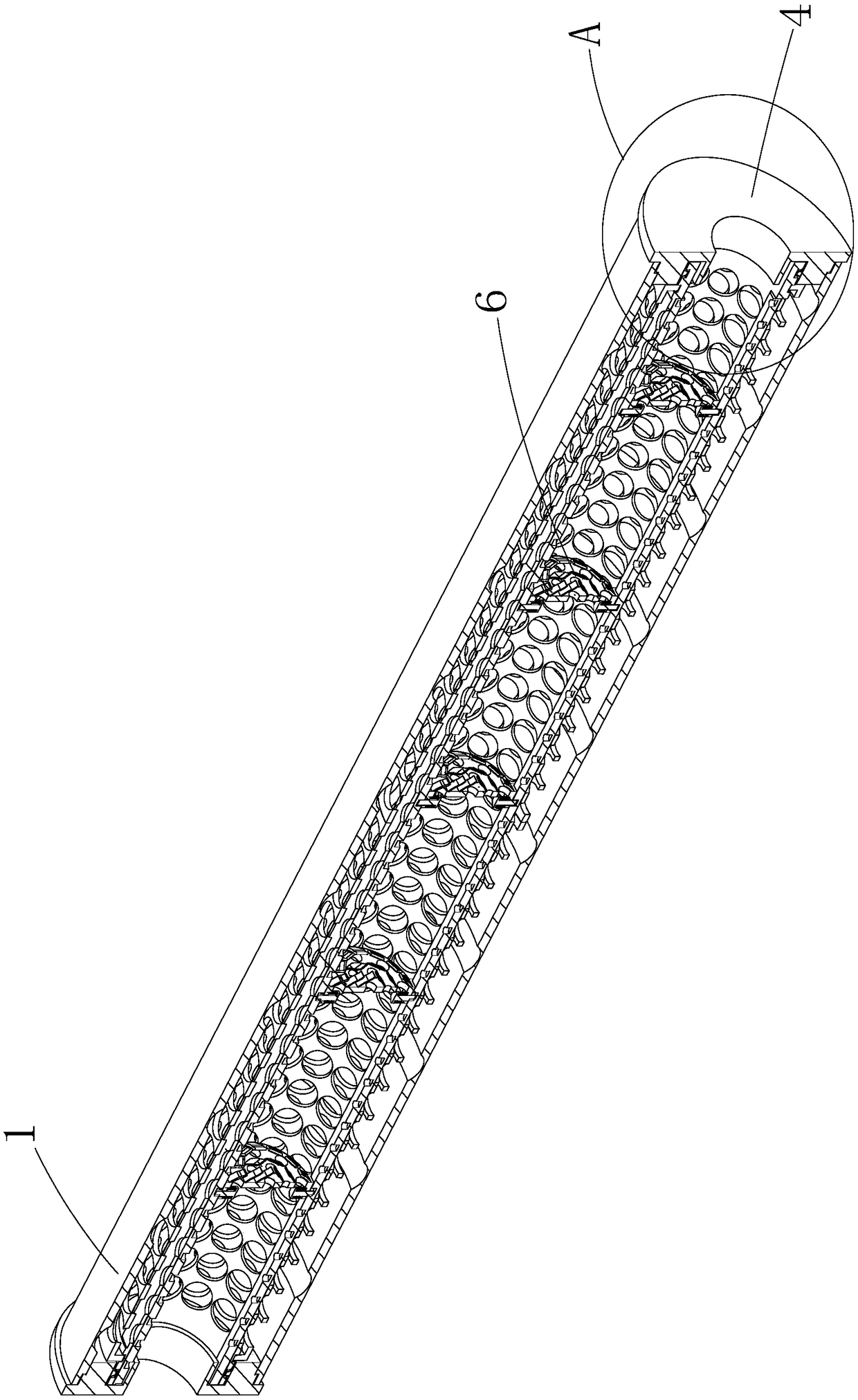

[0043] Such as Figure 1-16Shown, a kind of solid-gas microchannel reactor comprises sleeve pipe 1, reaction tube 2, catalytic structure 3, a plurality of drainage structures 6 and sealing structure 4, wherein said sleeve pipe 1 is a metal tube, and the sleeve pipe The end of 1 is provided with an external thread, and the end of the casing 1 can be connected to reaction microchannels of different specifications and sizes through the thread, and the gas is transported into the casing 1 through the reaction microchannel; the reaction tube 2 is also a metal microchannel. Channel, the reaction tube 2 is provided with a plurality of ventilation openings 20, the ventilation openings 20 can allow the gas entering the reaction tube 2 to flow out through the ventilation openings 20, and then enter the casing 1; and in the reaction The pipe 2 is concave downward except for both ends, and it is formed with a placement recess 24, and the catalytic structure is arranged in the placement re...

Embodiment 2

[0053] Such as Figure 17-20 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment discloses a filter structure 9 for filtering the gas to filter out solid impurities contained in the gas before the gas enters the reaction tube 2, specifically: the Described filter structure 9 comprises air intake pipe 91, filter 92 and air outlet pipe 93, wherein said air intake pipe 91 and air outlet pipe 93 are all a metal microchannel, and one end of said air inlet pipe 91 is connected to the outlet pipe 93. The phase screw connection of air pipe part 93, the other end of air intake pipe part 91 is movably connected with a metal connection nut 910, and the concrete connection mode of its connection nut 910 is prior art; The filter 92 is a metal filter cartridge with dense filter holes, and the filter 92 is detachably connected to the outlet pipe 93 .

[0054] Specifically, a connection platform 931 is provided on the outlet pipe piece 93, and a screw co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com