Three-component compound catalyst, as well as preparation method and application thereof

A ternary composite and catalyst technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc. High efficiency, lower costs, and the effect of being conducive to industrialization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

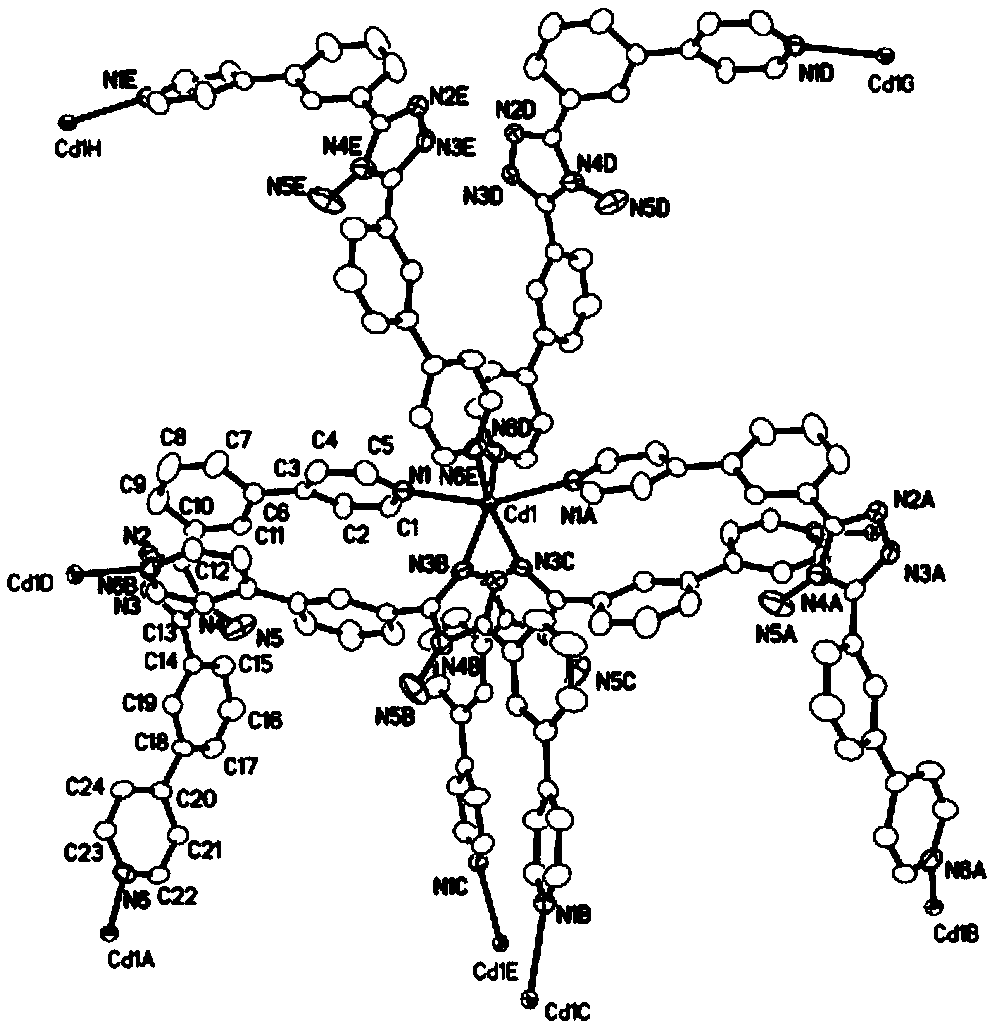

[0052] Example 1 : NaYF 4 :Yb,Tm@Cd-MOF@TiO 2 preparation of

[0053] Formulated with Cd(BF 4 ) 2 (60mg, 0.186mmol), 25mg NaYF 4 : Yb, Tm and 0.1g PVP homogeneous turbid solution of 2mL water, preparation containing 4-amino-3,5-bis(4-pyridine-3-phenyl)-1,2,4-triazole (46.4mg ,0.100mmol) of 3mL methanol solution, add the aqueous turbid solution dropwise to the ligand-containing methanol solution, sonicate for 10min to form a gel, add 20mgTiO 2 NPs, stirred evenly, stood still for 12 hours, centrifuged, soaked and washed with ethanol three times, and dried at 80°C for 12 hours to obtain NaYF 4 :Yb,Tm@Cd-MOF@TiO 2 , represented by the structural formula as 7.15NaYF 4 :Yb,Tm@4.77Cd 2 (C 20 h 18 N 6 )@TiO 2 .

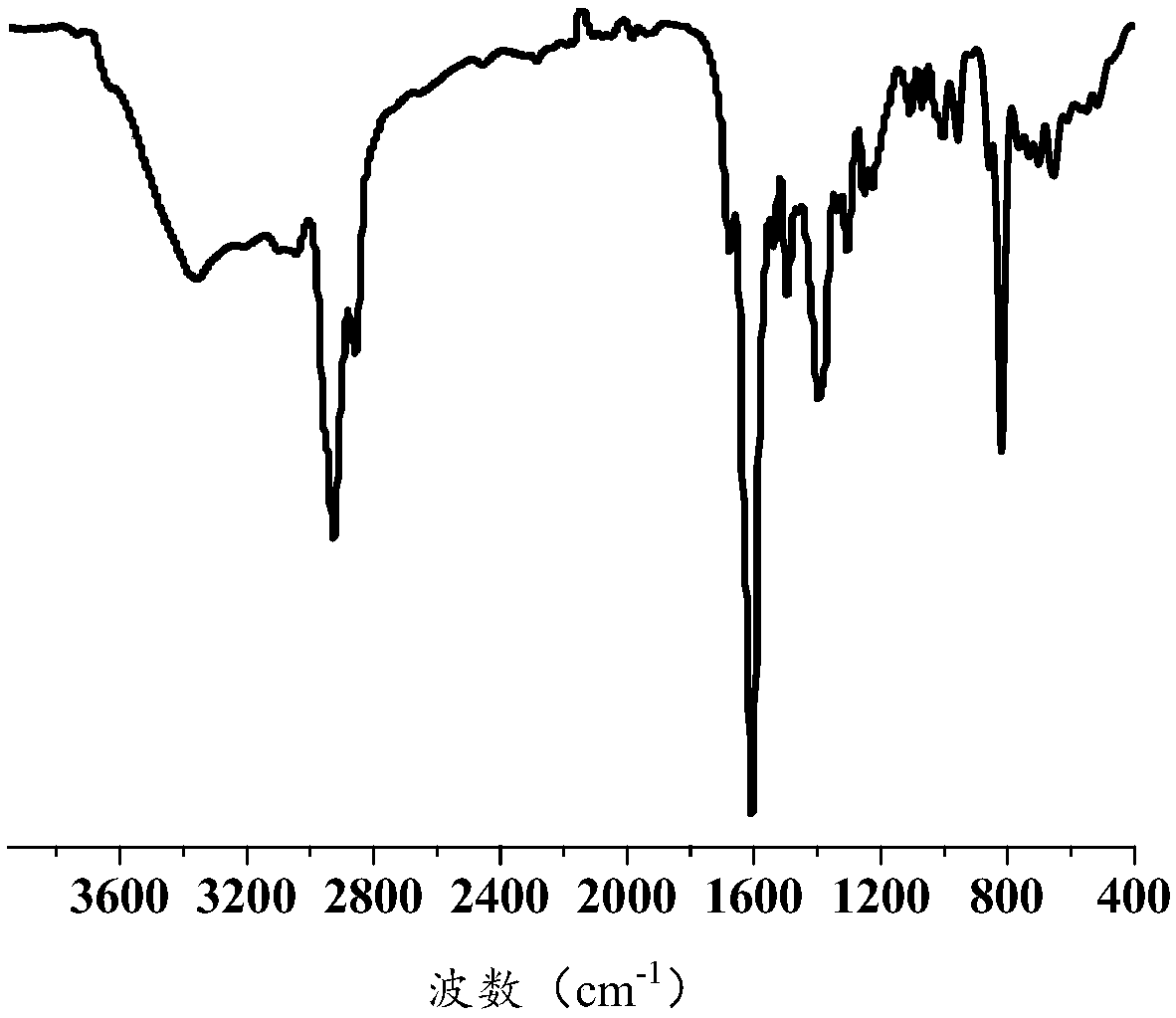

[0054] To the NaYF prepared in this embodiment 4 :Yb,Tm@Cd-MOF@TiO 2 For characterization, the IR spectrum is as figure 2 As shown, the SEM pattern is as image 3 Shown, the X-ray powder diffraction spectrum is shown as Figure 4 Shown, the ICP analysis ...

experiment example 2

[0058] Experimental example 2 : NaYF 4 :Yb,Tm@Cd-MOF@TiO 2 Photodegradation of dyes in water

[0059] Aqueous solution of methylene blue (10 -5 mol / L, 5ml) into the quartz cell, then add 5mg catalyst NaYF 4 :Yb,Tm@Cd-MOF@TiO 2 (prepared in Example 1), stirred for 5-10min, and then with a wavelength of 980nm and a power of 10w infrared lamps to irradiate the aqueous solution of the quartz cell, after the dye degradation reaction was completed, the catalyst was quickly centrifuged to reclaim the catalyst (98% recovery by mass) ), directly into the next photodegradation reaction, according to the above conditions, the catalyst is used for 5 cycles, and the degradation rate is calculated by ultraviolet spectrum testing, and the degradation effect is as follows: Figure 7 And shown in Table 2. The recovered catalyst was characterized by PXRD, NaYF 4 :Yb,Tm@Cd-MOF@TiO 2 Still keep the original frame (PXRD picture as Figure 8 shown).

[0060] Table 2NaYF 4 :Yb,Tm@Cd-MOF@...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com