Separation device and separation method for separating micro-plastic and cellulose crystals in soil

A cellulose crystallization and separation device technology, applied in centrifuges and other directions, can solve the problems of small size of microplastics and crystalline cellulose, inability to achieve sample solution separation work, and mixed sediment, saving experimental raw materials and improving accuracy. and effectiveness, improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

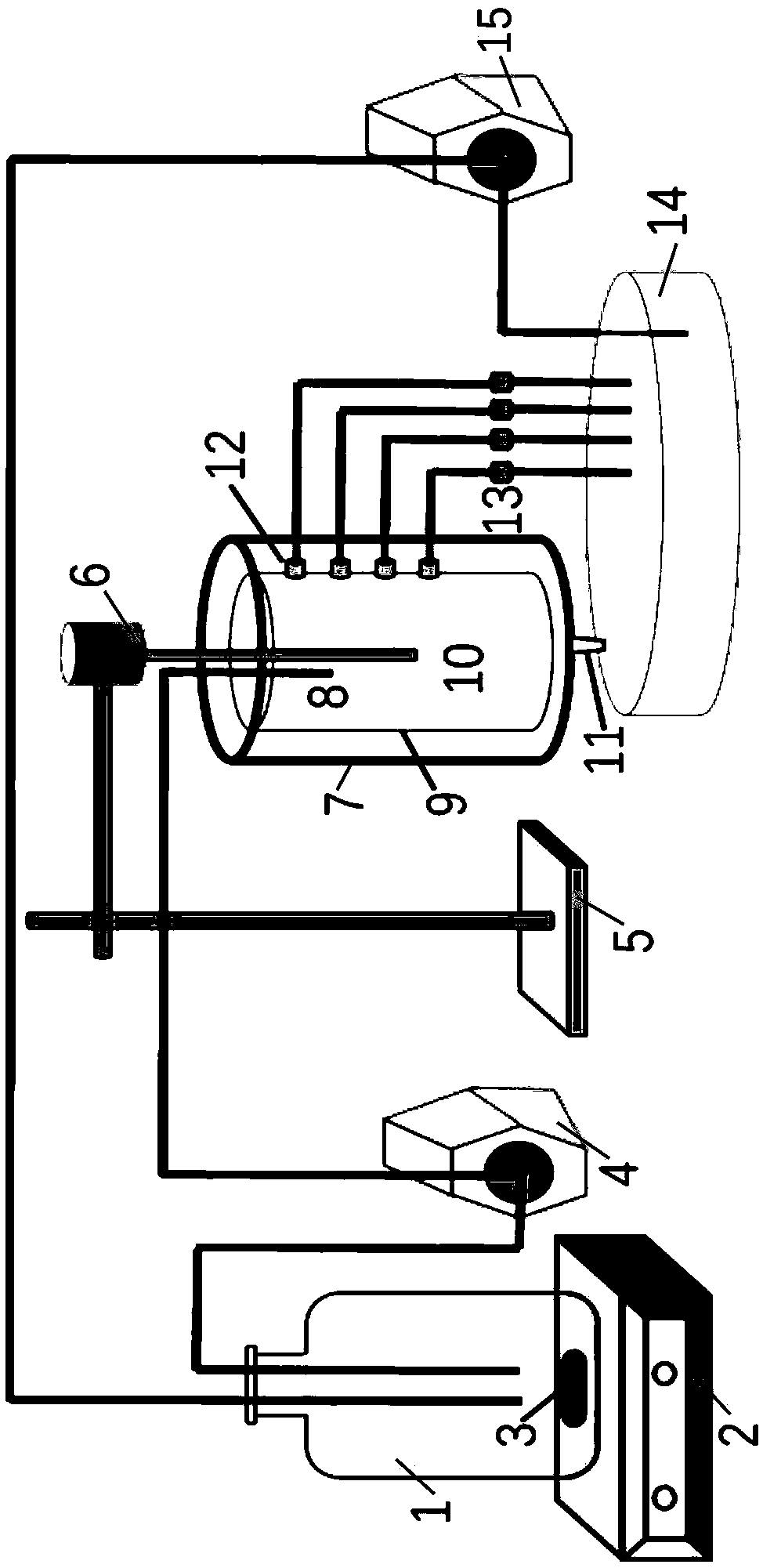

[0024] In order to better understand the purpose, function and specific design of the present invention, the separation device and separation method for separating microplastics and cellulose crystals in soil according to the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] The separation device for separating microplastics and cellulose crystals in soil of the present invention includes a sample preparation system, a fractional separation system, a fractional collection system and a circulation system. Among them, the sample preparation system is set at the front end of the separation device to prepare the soil suspension; the fractionation separation system is set behind the sample preparation system and connected to the pipeline of the sample preparation system, and the soil suspension flows into the fractionation system through the pipeline, The fractionation is carried out in the fractionation system; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com