Round pipe welding device for industrial machine

A technology for welding equipment and industrial machinery, applied in auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of uniform rotation and difficulty of circular pipe, and achieve the effect of improving work efficiency, improving applicability, and ensuring vertical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

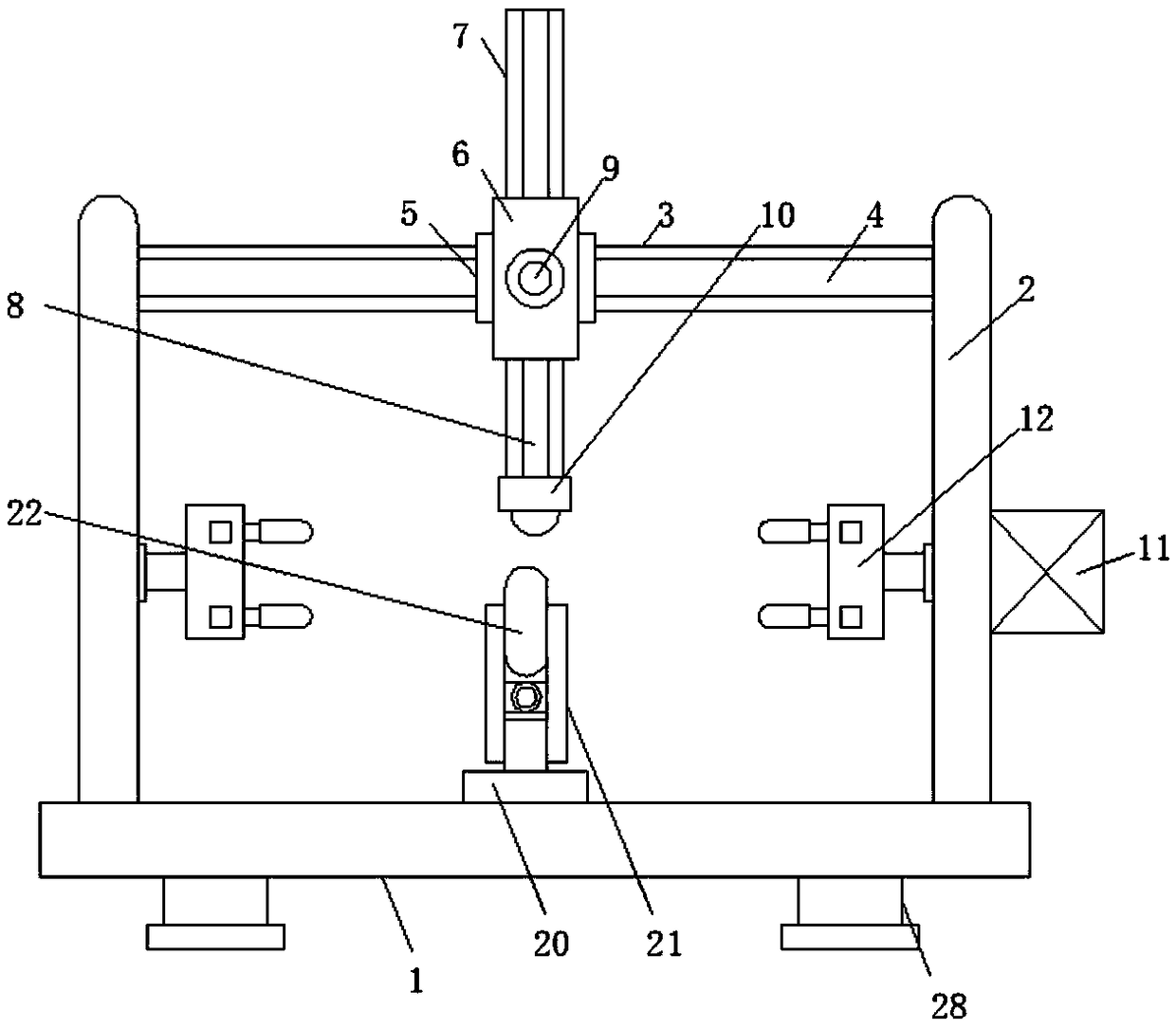

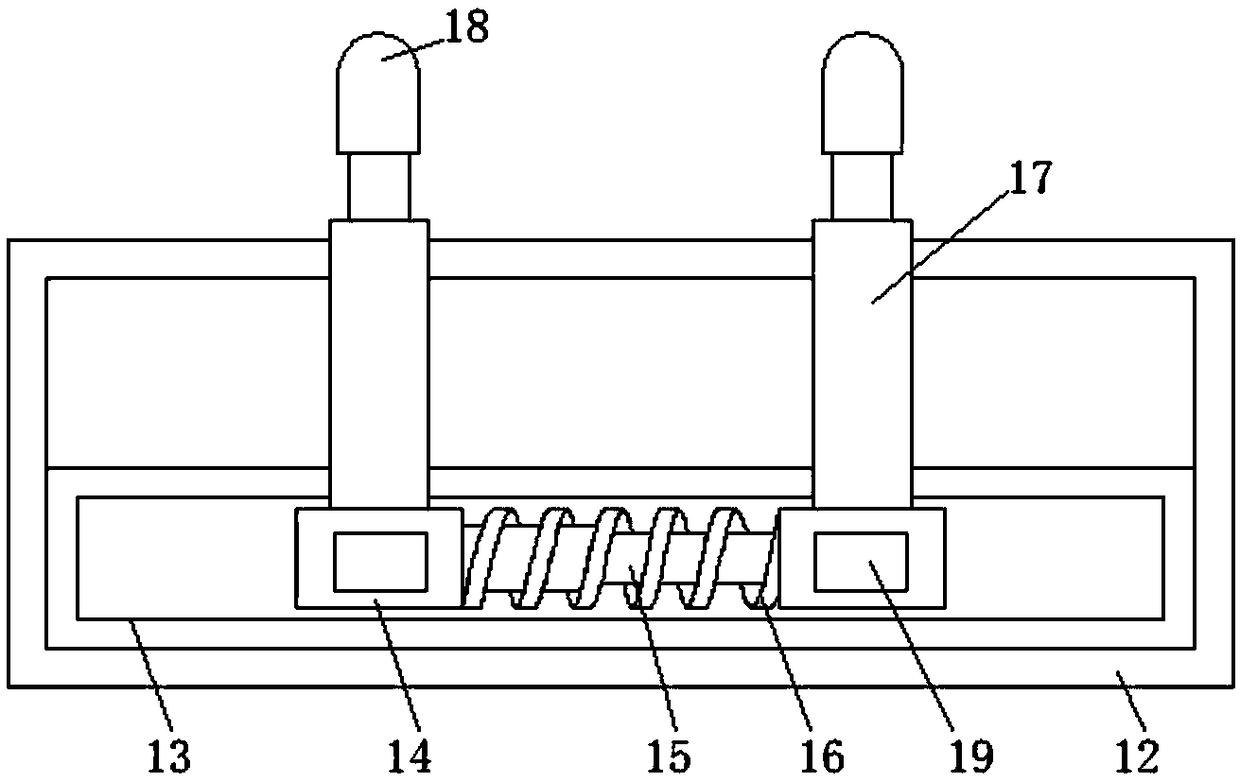

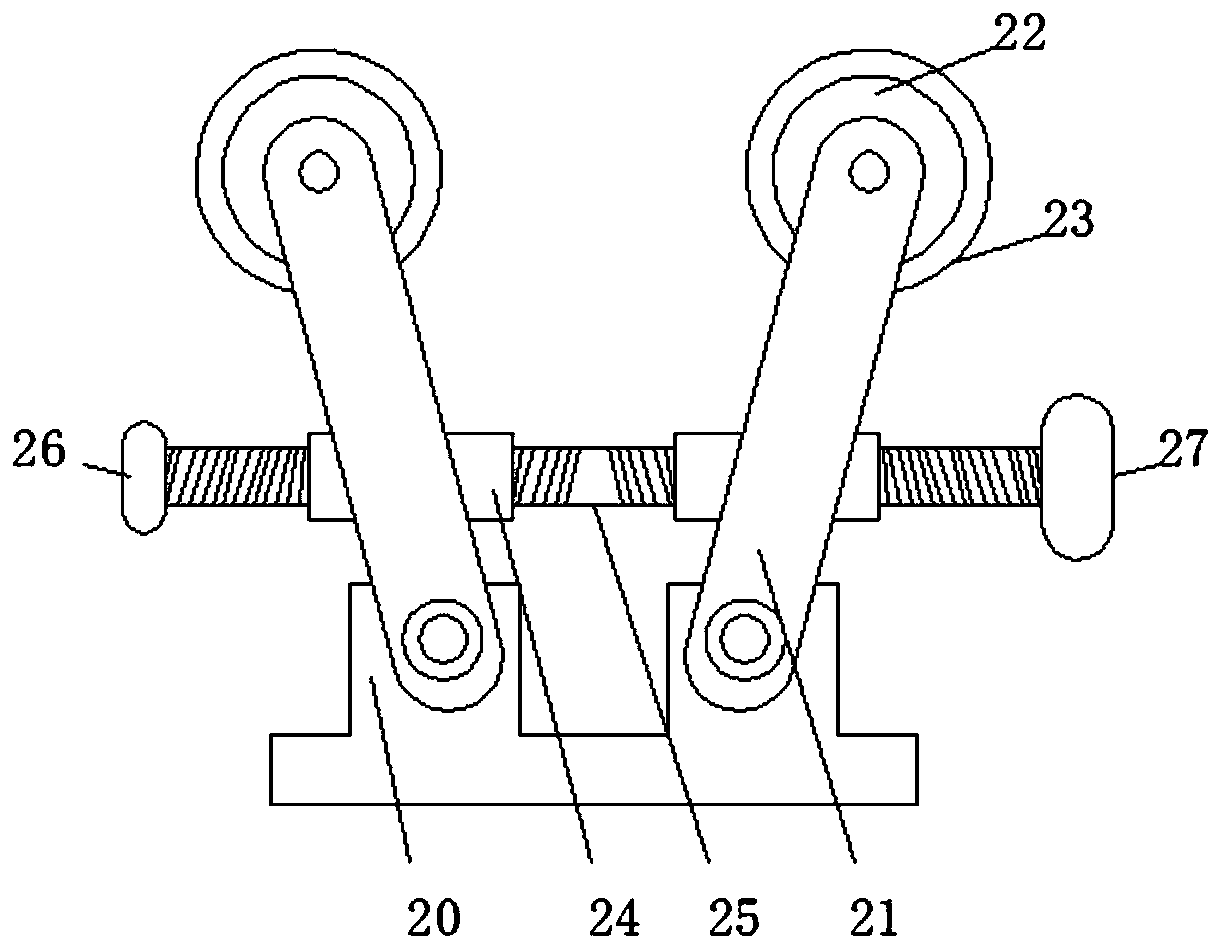

[0022] Such as Figure 1-3 As shown, the present invention provides a technical solution: a round pipe welding device for industrial machinery, including a bottom plate 1, the middle position of the top of the bottom plate 1 is fixedly connected with a hinged seat 20, and the two sides of the front of the hinged seat 20 are respectively connected to the The bottom of the front of the articulated rod 21 is hinged, and the top of the articulated rod 21 is connected with a support wheel 22 through a pin shaft rotation, and the outer wall of the articulated rod 22 is fixedly connected with a rough layer 23, and the middle position of the back of the articulated rod 21 is fixedly connected with a threaded sleeve 24, the threaded sleeve 24 is threadedly connected with a threaded rod 25, the left end of the threaded rod 25 is fixedly connected with the limit block 26, and the right end of the threaded rod 25 is fixedly connected with the adjustment block 27, and the setting of the tub...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap