Multifunctional machine tool limiting device

A multi-functional machine tool and limit device technology, applied in feeding devices, metal processing machinery parts, metal processing, etc., can solve problems such as difficult stop, easy drop of contacts, machine tool impact, etc., to prevent mechanical collisions and improve reliability Effects on sex and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

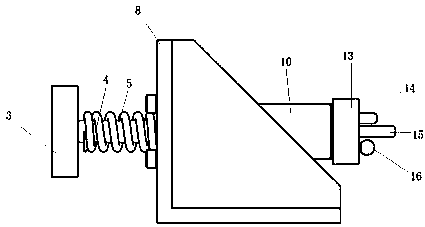

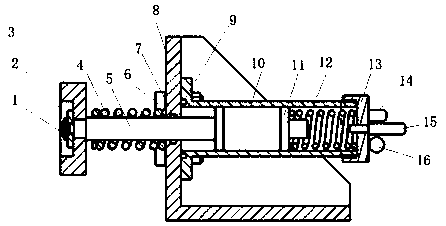

[0013] A limit device for a multifunctional machine tool, comprising a hydraulic buffer mechanism and a detection and feedback element. The base L plate 8 is fixedly installed on the machine tool, the hydraulic buffer mechanism is fixedly installed on the base L plate 8 , and the detection feedback element is installed on the end face 13 of the hydraulic buffer mechanism.

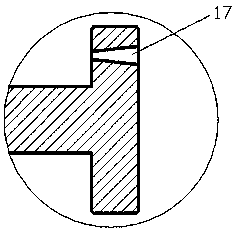

[0014] The hydraulic buffer mechanism is used to block the movement displacement of the machine tool moving unit, including screw 1, pressure plate 2, baffle plate 3, external compression spring 4, external piston rod 5, bolt 6, horizontal sealing ring 7, base L plate 8, vertical sealing Ring 9, flange 10, inner piston 11, inner compression spring 12, end cap 13. The end plate 3 is fixedly connected with the outer piston rod 5 through the screw 1, the outer compression spring 4 is set on the outer piston rod 5, one end of the flange 10 is fixedly connected with the base L plate 8 through the bolt 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com