Sediment treating device for recovering wastewater of enterprise

A waste water recovery and treatment device technology, which is applied in the direction of processing waste water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of increasing the footprint of treatment equipment, increasing the cost of waste water treatment manufacturers, and increasing the cost of waste water treatment and other problems, to achieve the effect of reducing floor space, reducing processing costs and increasing flocculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

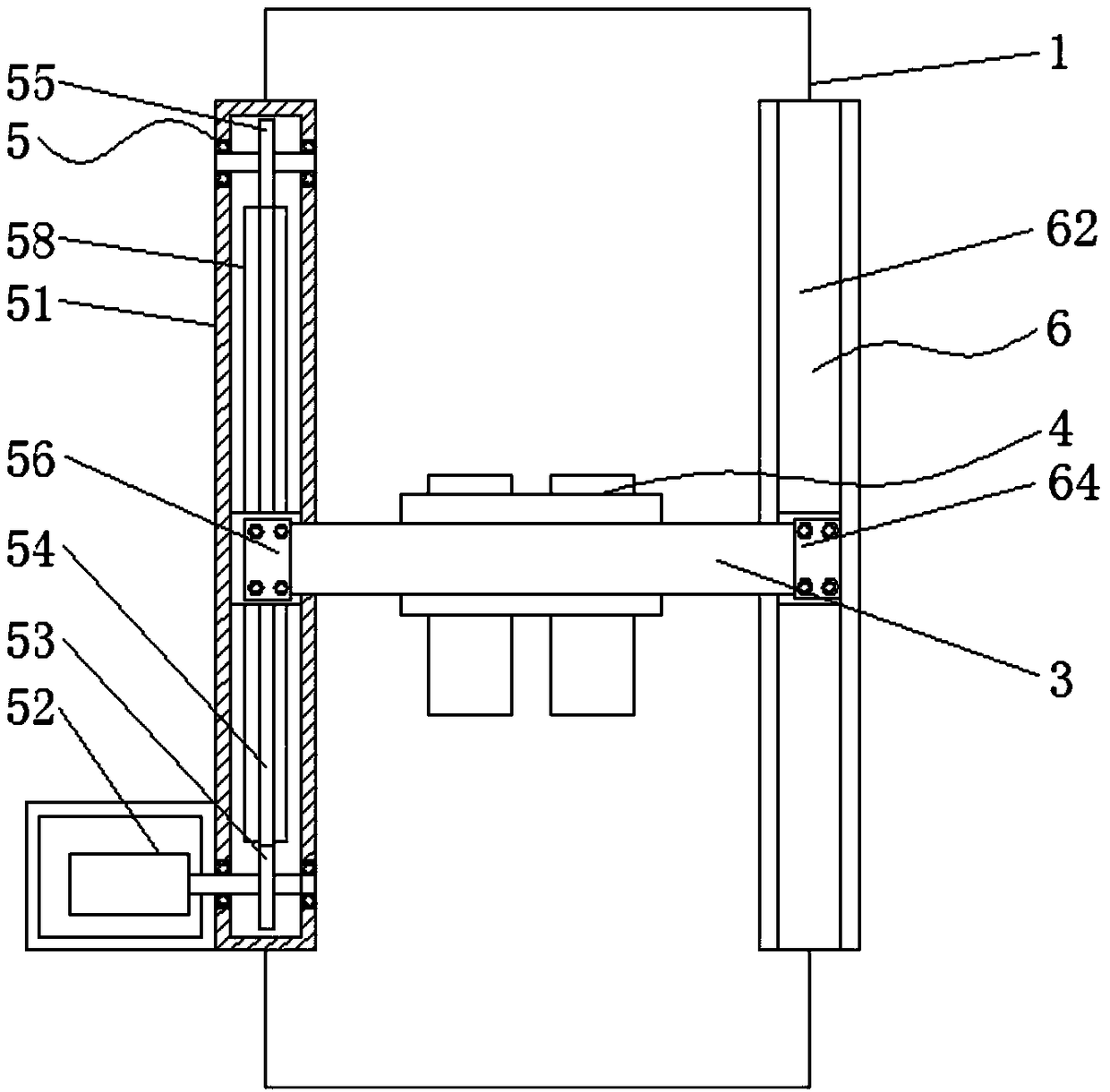

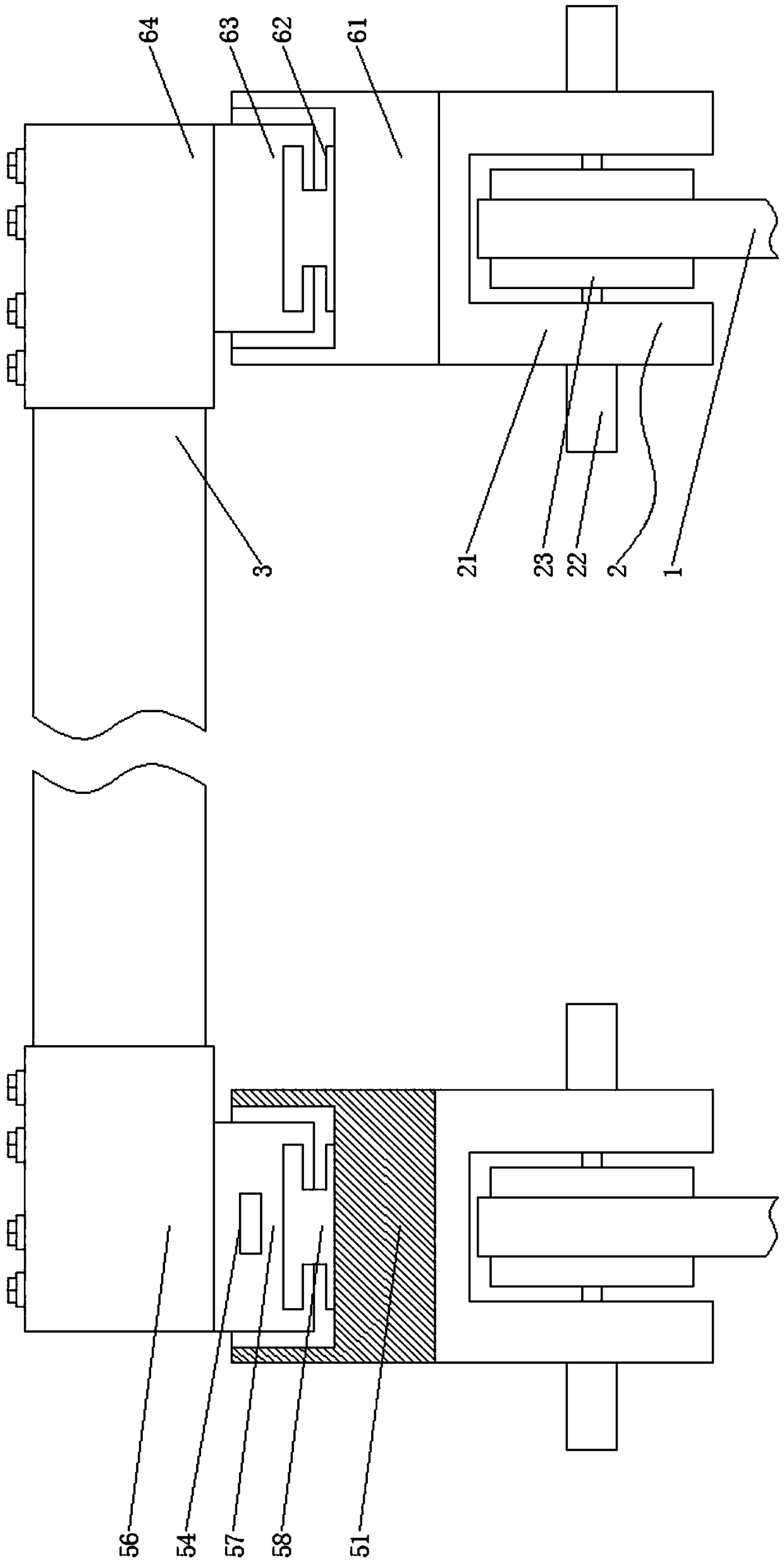

[0023] combine Figure 1-Figure 8 This embodiment discloses a filter device for recycling waste water in a papermaking enterprise, comprising a waste water collection tank 1, a fixing device 2, a support beam 3, and a walking filter device 4; the waste water collection tank 1 is provided with mobile drive devices on both sides. 5 and a moving driven device 6, the moving driving device 5 and the moving driven device 6 are respectively arranged on the two ends of the waste water collection tank 1 through two sets of fixing devices 2, and the moving driving device 5 and the moving driven device 6 A support beam 3 is arranged between them, and the walking filter device 4 is arranged on the support beam 3; one end of the waste water collection tank 1 is connected with the waste water outlet pipe through a pipeline, and the other end of the waste water collection tank 1 It is connected with the recycling pipeline through the pipeline, and a set of sediment treatment device 7 is also...

Embodiment 2

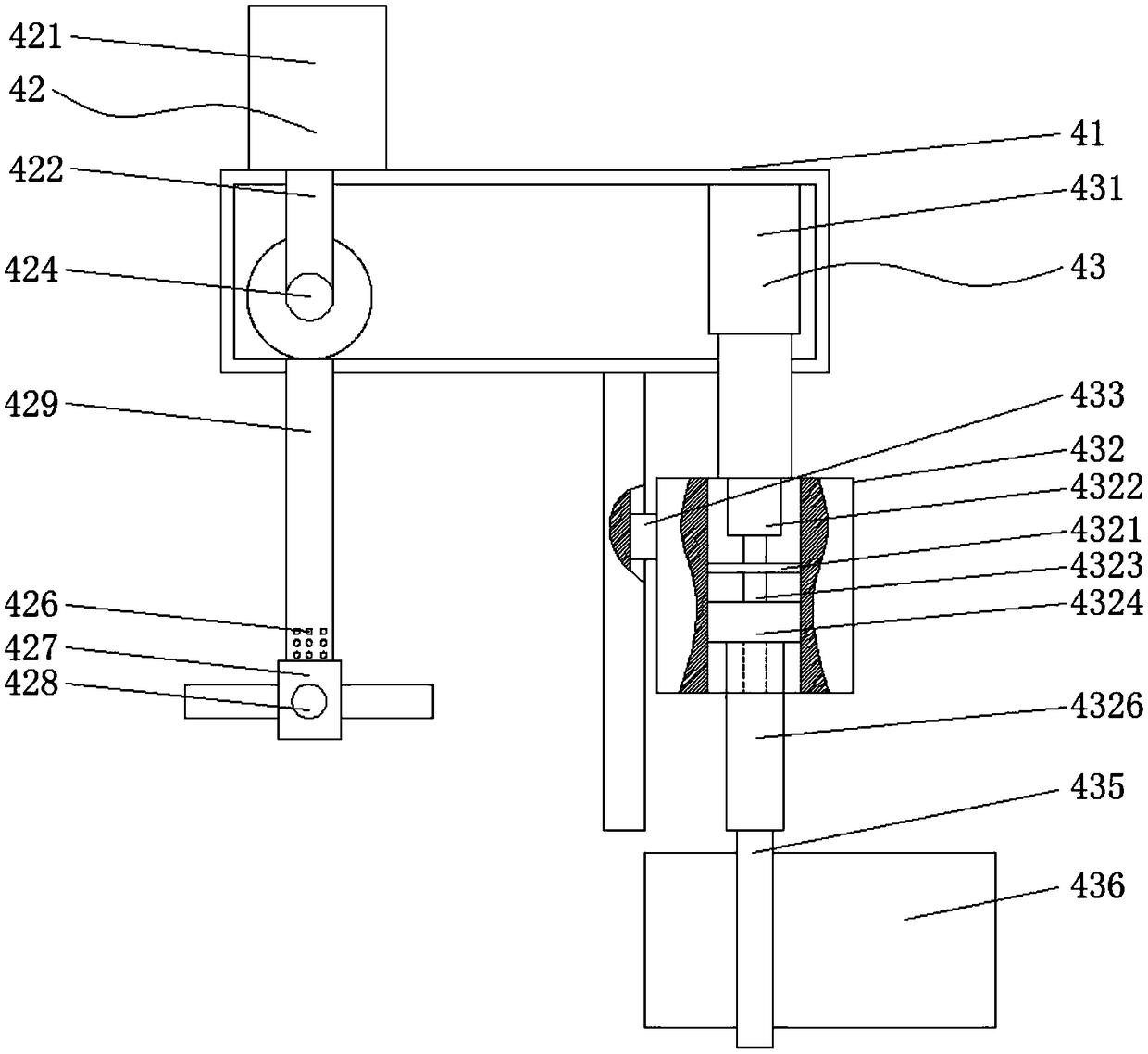

[0028] On the basis of Embodiment 1, the flocculation device 42 includes several sets of flocculant cylinders 421, all of which are fixed on the upper end of the installation frame 41 through a fixing frame, and the interior of the flocculant cylinders 421 is filled with Flocculants, each set of flocculant cylinders 421 is processed with a set of discharge holes at the lower end, and a set of discharge pipes 422 are arranged in the discharge holes, and all the discharge pipes 422 communicate with a set of first intermediate connecting pipes 423 , the first intermediate connecting pipe 423 is connected to a group of flocculation pumps 424 through a high-pressure pipe, and the other end of the flocculation pump 424 is connected to a second intermediate connecting pipe 425 through a high-pressure pipe, and the second intermediate connecting pipe 425 is connected to several sets of The flocculation discharge pipe 422 is connected, the end of the flocculation discharge pipe 422 is s...

Embodiment 3

[0030]Based on the second embodiment, in this implementation, each set of discharge pipes 422 is provided with a set of electronically controlled one-way valves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com