Easily-stripped environmentally-friendly film, and bamboo chopstick adsorbing technology thereof

An easy-to-peel, environmentally-friendly technology, which is applied to tableware, applications, and home appliances, can solve problems affecting degradation performance and achieve the effects of easy-to-peel film, environmental protection, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

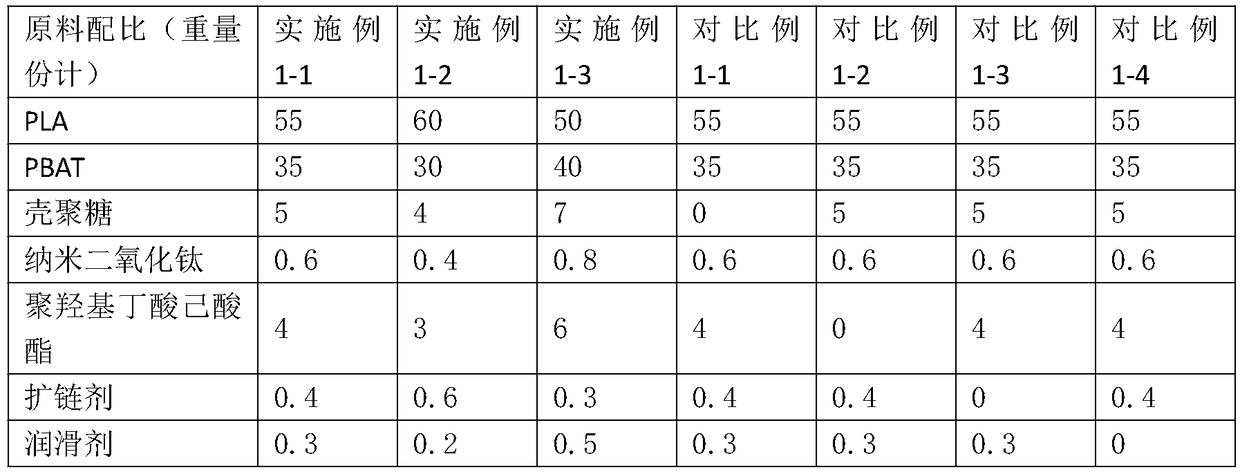

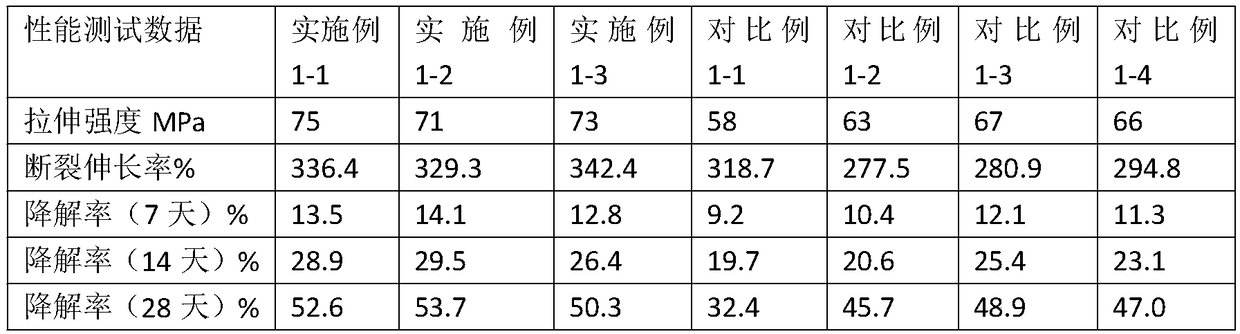

Embodiment 1

[0031] An easy-to-peel environmentally friendly film, comprising the following components: polylactic acid (PLA), poly(butylene terephthalate-co-hexanediol butanediol) ester (PBAT), chitosan, nano-titanium dioxide, poly Hydroxybutyrate caproate, chain extender and lubricant. Among them, the weight average molecular weight of PLA is 1.35×10 5 g·mol -1 ;PBAT weight average molecular weight 4×10 5 g·mol -1 ; The chain extender is KL-E4370; the lubricant is ethylene bis stearic acid amide.

[0032] Preparation method: 1) Preparation of environmentally friendly film modified material: according to the above ratio, polylactic acid (PLA), poly(butylene terephthalate-co-hexanediol butanediol) ester (PBAT), chitosan Sugar, nano-titanium dioxide, polyhydroxybutyrate caproate, chain extender and lubricant are mechanically blended, and the uniformly mixed raw materials are put into the hopper of a twin-screw extruder, melt-extruded and granulated to obtain an environmentally friendly ...

Embodiment 2

[0048] An easy-to-peel environment-friendly film, comprising the following components: 65 parts of polylactic acid (PLA), 40 parts of poly(butylene terephthalate-co-hexanediol butanediol) ester (PBAT), 2 parts of chitosan 1 part, 1 part of nano-titanium dioxide, 8 parts of polyhydroxybutyrate caproate, 0.2 part of chain extender and 0.8 part of lubricant. Among them, the weight average molecular weight of PLA is 1.6×10 5 g·mol -1 ; PBAT weight average molecular weight 4.2 × 10 5 g·mol -1 ; The chain extender is KL-E4300; the lubricant is ethylene bis stearic acid amide.

[0049] Preparation method: 1) Preparation of environmentally friendly film modified material: according to the above ratio, polylactic acid (PLA), poly(butylene terephthalate-co-hexanediol butanediol) ester (PBAT), chitosan Sugar, nano-titanium dioxide, polyhydroxybutyrate caproate, chain extender and lubricant are mechanically blended, and the uniformly mixed raw materials are put into the hopper of a tw...

Embodiment 3

[0054] An easy-to-peel environment-friendly film, comprising the following components: 65 parts of polylactic acid (PLA), 45 parts of poly(butylene terephthalate-co-hexanediol butanediol) ester (PBAT), 10 parts of chitosan 0.1 part of nano-titanium dioxide, 7 parts of polyhydroxybutyrate caproate, 0.8 part of chain extender and 0.1 part of lubricant. Among them, the weight average molecular weight of PLA is 1.2×10 5 g·mol -1 ; PBAT weight average molecular weight 3.8 × 10 5 g·mol -1 ; The chain extender is KL-E4370; the lubricant is ethylene bis stearic acid amide.

[0055] Preparation method: 1) Preparation of environmentally friendly film modified material: according to the above ratio, polylactic acid (PLA), poly(butylene terephthalate-co-hexanediol butanediol) ester (PBAT), chitosan Sugar, nano-titanium dioxide, polyhydroxybutyrate caproate, chain extender and lubricant are mechanically blended, and the uniformly mixed raw materials are put into the hopper of a twin-sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com