Metal plate strip rolling quenching speed control system and method

A metal strip and speed control technology, which is applied in heat treatment process control, manufacturing tools, heat treatment equipment, etc., can solve problems such as low efficiency, inoperable roller tables, and out-of-synchronization of roller table speeds, so as to improve production efficiency and improve Accurate effect on surface quality and roll speed control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

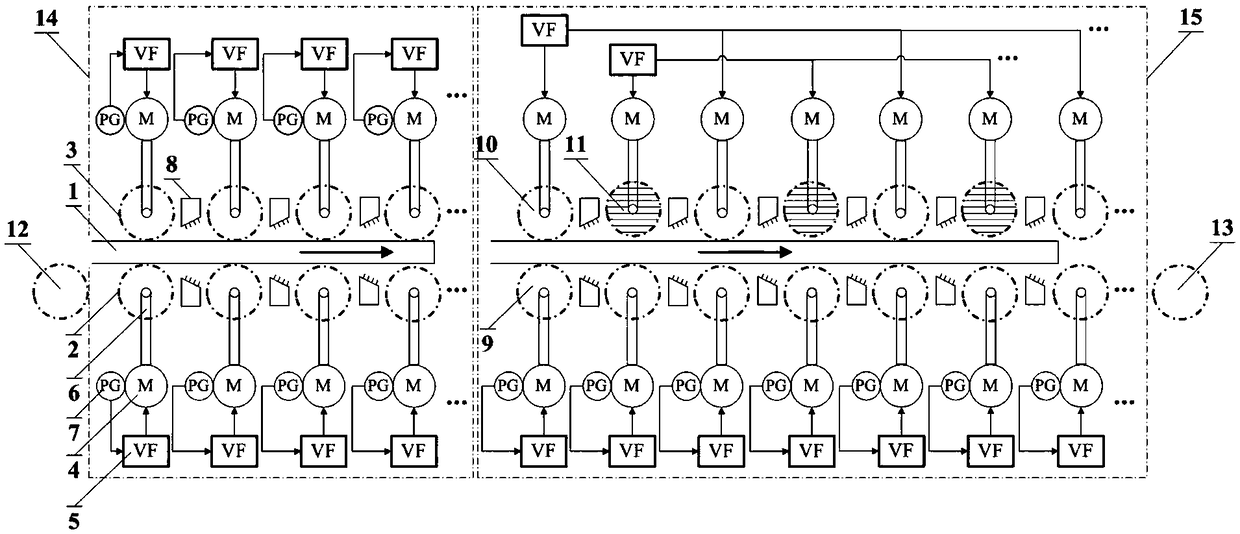

[0024] Embodiment 1, this embodiment provides the implementation process of a metal plate and strip roller quenching speed control system of the present invention, such as figure 1 shown. Roller table transmission system 14 in the high-pressure area. Each roller table transmission motor 4 controls the lower load-bearing roller table 2 in the high-pressure area and the upper restraint roller table 3 in the high-pressure area through a separate transmission connection mechanism 6. Start and stop, the actual speed of each roller table is measured by the roller table encoder 7 installed on the roller table transmission motor 4 and fed back to the corresponding transmission frequency conversion system 5, the transmission frequency conversion system 5 is based on the feedback roller table speed to the roller table transmission motor 4 Implement closed-loop vector control; roller table transmission system 15 in the low pressure area, each roller table drive motor 4 controls each roll...

Embodiment 2

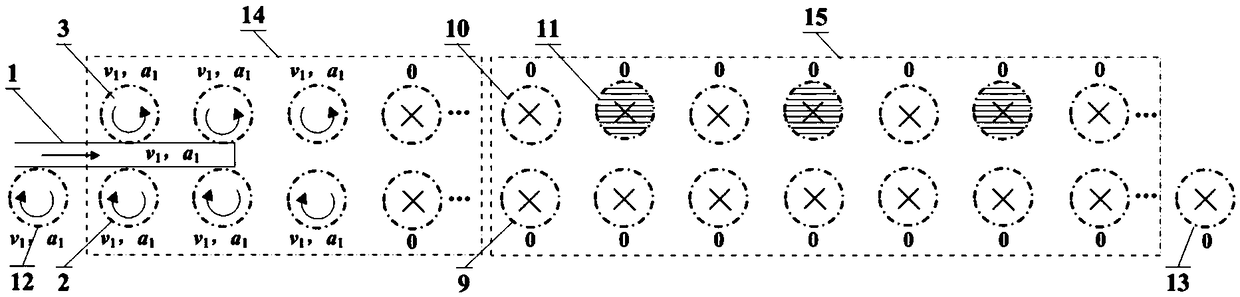

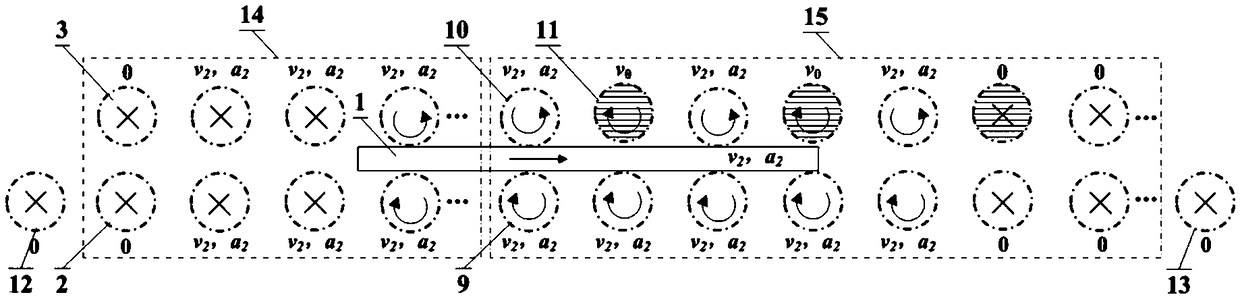

[0025] Embodiment 2, this embodiment provides the implementation process of a method for controlling the speed of roller quenching of metal plates and strips according to the present invention, such as figure 1 , 2 , 3, 4, and 5, use 60mm thick, 3000mm wide, and 8m long metal strips as an example to illustrate the implementation process. After the metal plate and strip 1 is heated, the initial speed v of the quenching and cooling process 1 When reaching the roller table 12 on the upstream side of the roller quenching machine, the roller table transmission system 14 in the high-pressure zone rotates forward at the same speed as the first bearing roller table 2 in the lower part of the high-pressure zone. The upper constraining roller table 3 in the high-pressure zone reverses at the same speed, and sends the metal plate and strip 1 into the high-pressure zone roller transmission system 14; when the metal plate and strip 1 reaches the high-pressure zone roller transmission system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com