High-modulus and low-extension polyester industrial yarns used for geofabric and production method thereof

A technology of polyester industrial yarn and geotextile, applied in the directions of stretch spinning, melt spinning, filament/thread forming, etc., can solve the problems of low tensile strength, fatigue resistance, low anti-aging ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

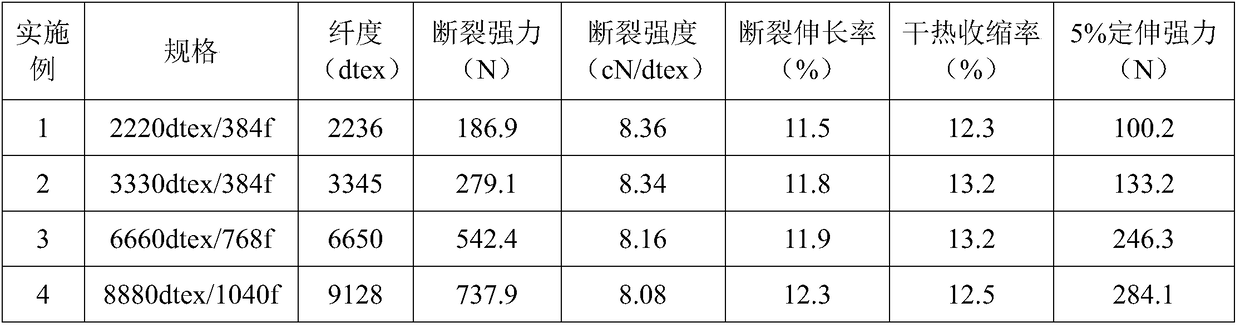

Examples

Embodiment 18

[0025] Example 18 Preparation of high modulus and low elongation polyester industrial yarn for spinning 2000D geotextile

[0026] The production method includes the following steps:

[0027] S1: Raw material ratio: raw material of high modulus low elongation polyester industrial yarn for geotextile, 50 to 70 parts of terephthalic acid, 20 to 30 parts of ethylene glycol, 0.018 to 0.035 parts of catalyst, and 0.35 to 0.75 parts of oil.

[0028] S2: Preparation of raw materials: Put terephthalic acid, ethylene glycol and catalyst into the vertical esterification tank 1 to carry out the first esterification reaction through the stirring of the stirring blade; the reaction products in the esterification tank 1 are transported to the horizontal via pipeline The esterification kettle 2 performs the second esterification reaction; after the two-step esterification reaction is completed, the reactants are transported to a stirred vertical reactor 3 for pre-condensation; the oligomer obtained ...

Embodiment 26

[0035] Example 26 Preparation of high modulus low elongation polyester industrial yarn for spinning 3000D geotextile

[0036] The production method includes the following steps:

[0037] S1: Raw material ratio: raw material of high modulus low elongation polyester industrial yarn for geotextile, 50 to 70 parts of terephthalic acid, 20 to 30 parts of ethylene glycol, 0.018 to 0.035 parts of catalyst, and 0.35 to 0.75 parts of oil.

[0038] S2: Preparation of raw materials: Put terephthalic acid, ethylene glycol and catalyst into the vertical esterification tank 1 to carry out the first esterification reaction through the stirring of the stirring blade; the reaction products in the esterification tank 1 are transported to the horizontal via pipeline The esterification kettle 2 performs the second esterification reaction; after the two-step esterification reaction is completed, the reactants are transported to a stirred vertical reactor 3 for pre-condensation; the oligomer obtained by t...

Embodiment 33

[0045] Example 33 Preparation of high modulus low elongation polyester industrial yarn for spinning 6000D geotextile

[0046] The production method includes the following steps:

[0047] S1: Raw material ratio: raw material of high modulus low elongation polyester industrial yarn for geotextile, 50 to 70 parts of terephthalic acid, 20 to 30 parts of ethylene glycol, 0.018 to 0.035 parts of catalyst, and 0.35 to 0.75 parts of oil.

[0048] S2: Preparation of raw materials: Put terephthalic acid, ethylene glycol and catalyst into the vertical esterification tank 1 to carry out the first esterification reaction through the stirring of the stirring blade; the reaction products in the esterification tank 1 are transported to the horizontal via pipeline The esterification kettle 2 performs the second esterification reaction; after the two-step esterification reaction is completed, the reactants are transported to a stirred vertical reactor 3 for pre-condensation; the oligomer obtained by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com