Venturi reversing device and urea reversed pumping device based on device

A reversing device, Venturi technology, applied in the direction of muffler, exhaust device, exhaust treatment, etc., can solve the problems that affect the reliability and service life of the urea pump assembly, poor sealing, large volume, etc., to avoid urea Deposition adhesion, low manufacturing cost, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

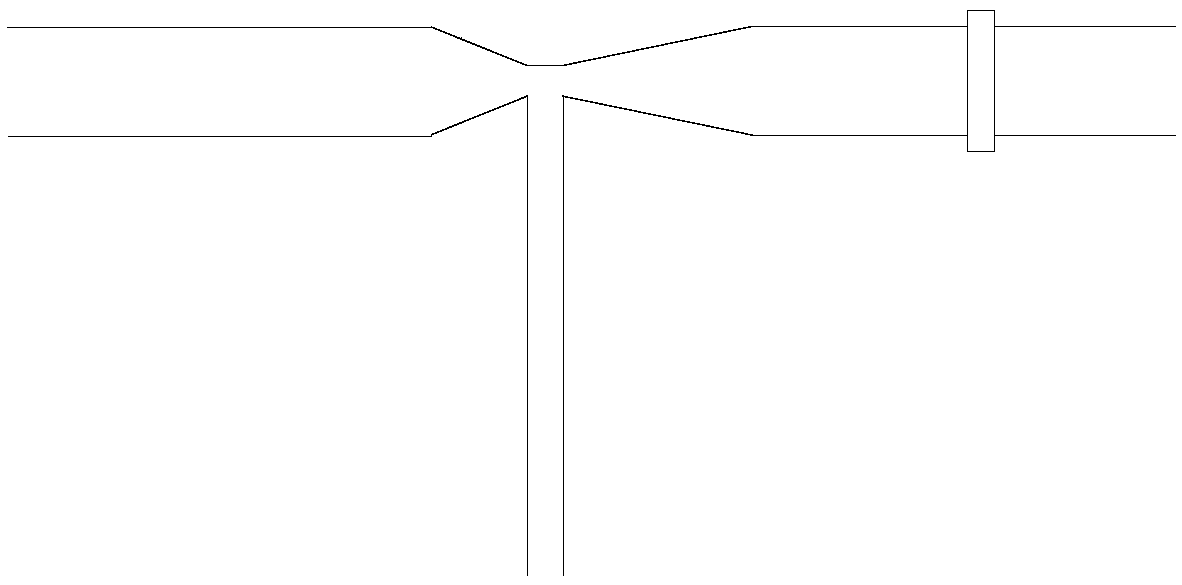

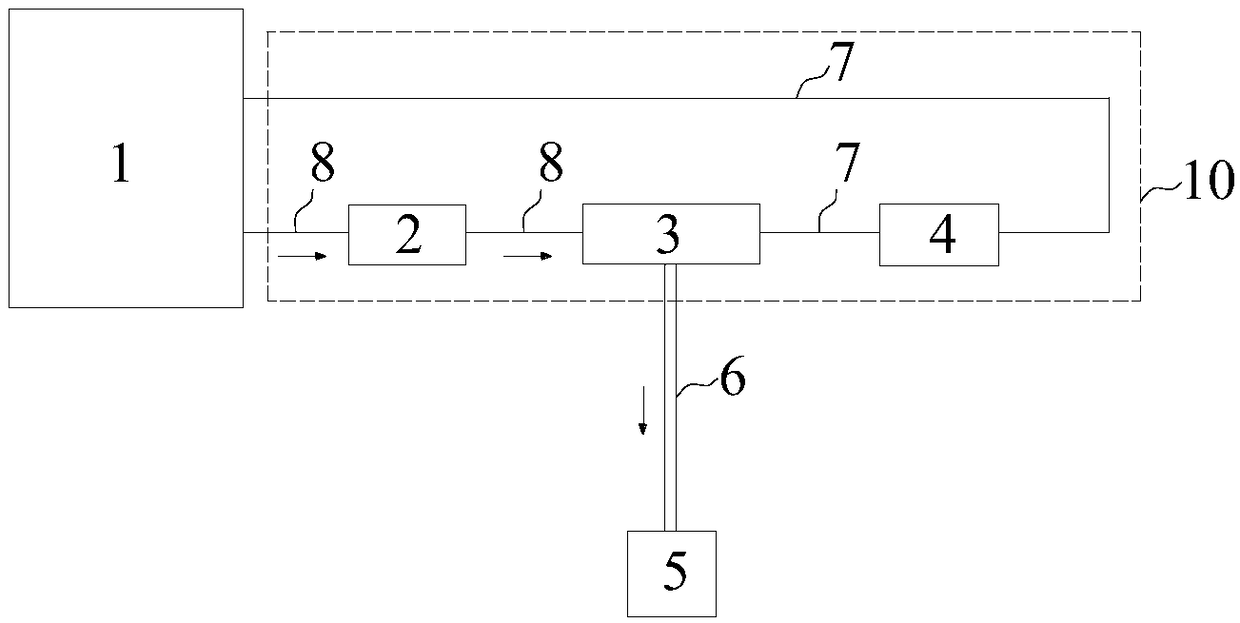

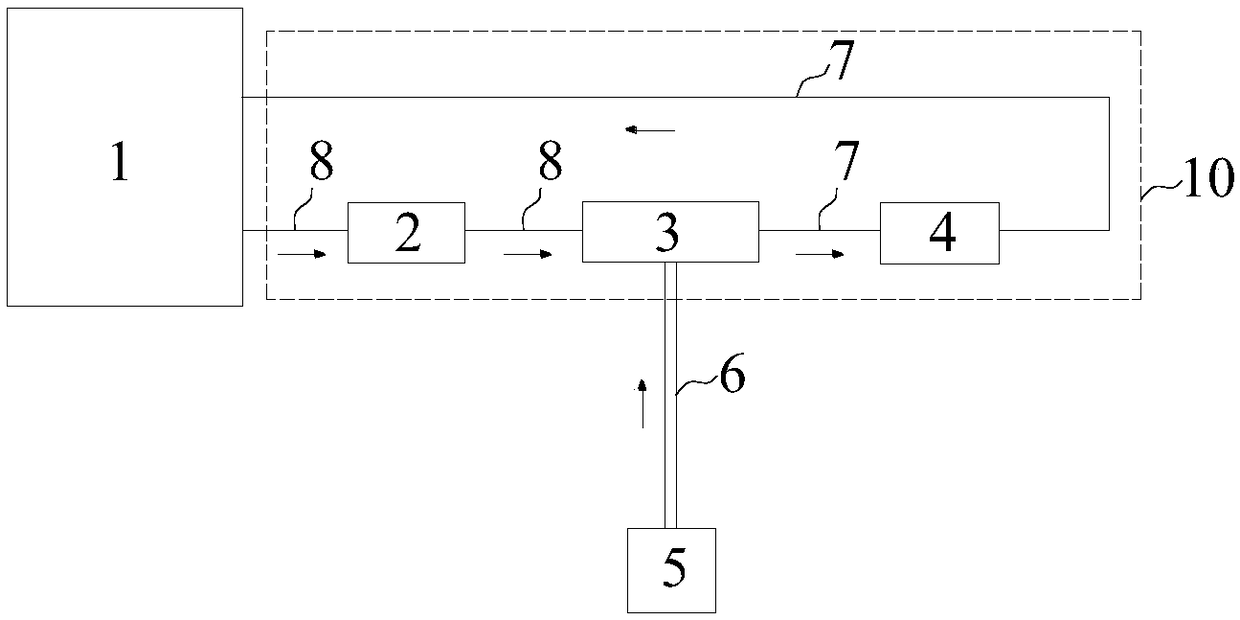

[0042] Such as figure 2 or image 3 As shown, the urea back pumping device includes a urea tank 1, a urea pump assembly 10, and an injection pipe 6, and the urea pump assembly 10 includes a urea tank 1, a booster pump 2, a Venturi tube 3, a liquid outlet pipe 8, a second A valve 4, the first liquid return pipe 7:

[0043] The urea tank 1, the booster pump 2 and the Venturi tube 3 are communicated through the liquid outlet pipe 8 to form the pipeline of the urea outflow part, and then the Venturi tube 3, the first valve 4 and the urea tank 1 are passed through the first loop The liquid pipe 7 is connected to form a complete urea circulation loop, and at the same time, the throat 302 of the Venturi pipe 3 is connected to the urea nozzle 5 through the injection pipe 6 .

Embodiment 2

[0045] Such as Figure 6 As shown, on the basis of the urea back pumping device in Embodiment 1, the outlet of the booster pump 2 and the first liquid return pipe 7 are communicated through the second liquid return pipe 9 to stabilize the pressure of the pipeline.

Embodiment 3

[0047] Such as Figure 7 As shown, on the basis of the urea back pumping device in Embodiment 1, the first valve 4 and the first liquid return pipe 7 are communicated through the second liquid return pipe 9 to stabilize the pressure of the pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com