A semi-open centrifugal pump impeller and its optimal design method

A centrifugal pump impeller, optimized design technology, applied in the field of centrifugal pump research, can solve the problems of blade outlet boundary layer separation, low dead center lift, front cover leakage, etc., to reduce swirl and cavitation, improve lift and efficiency , The effect of improving pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

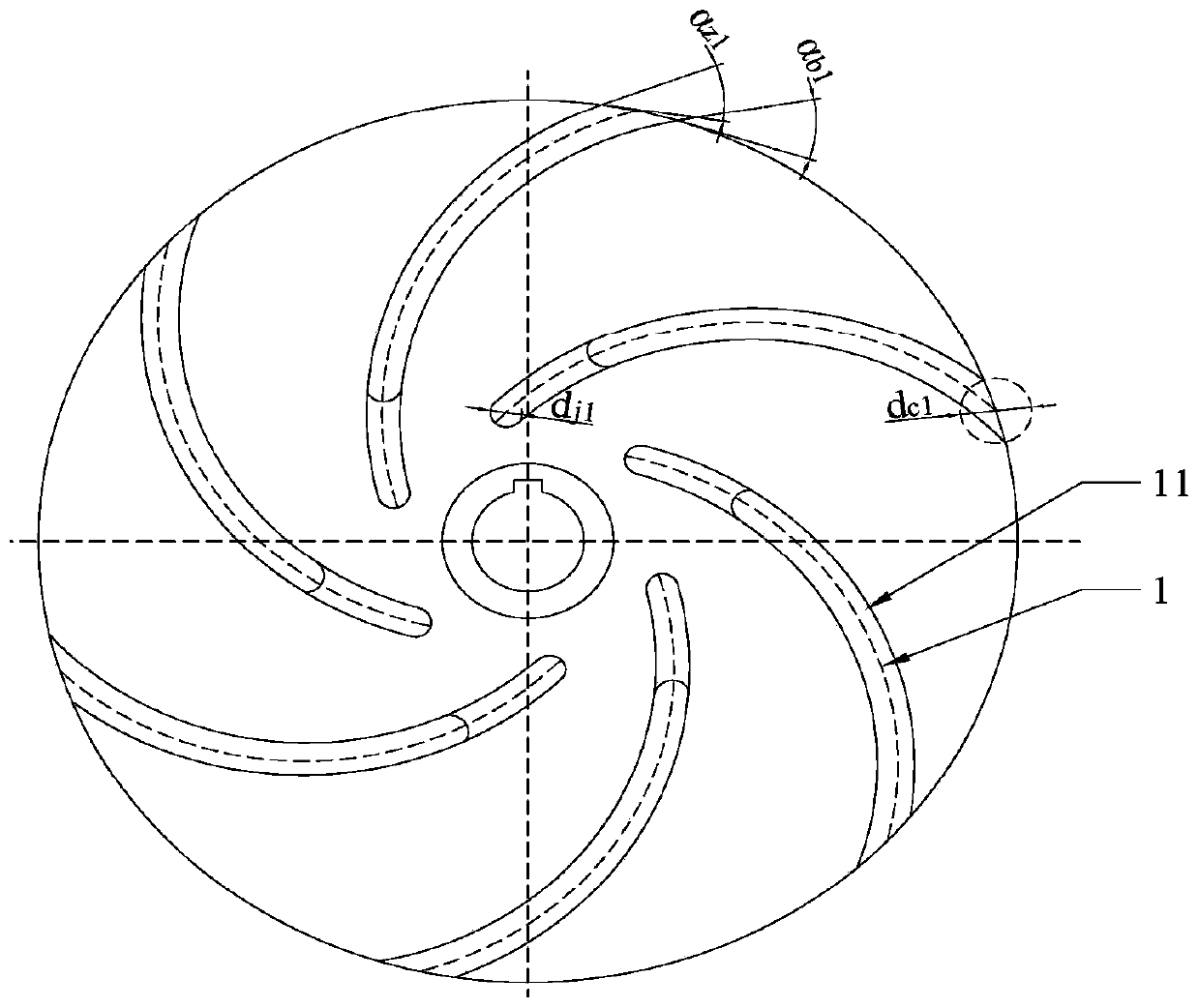

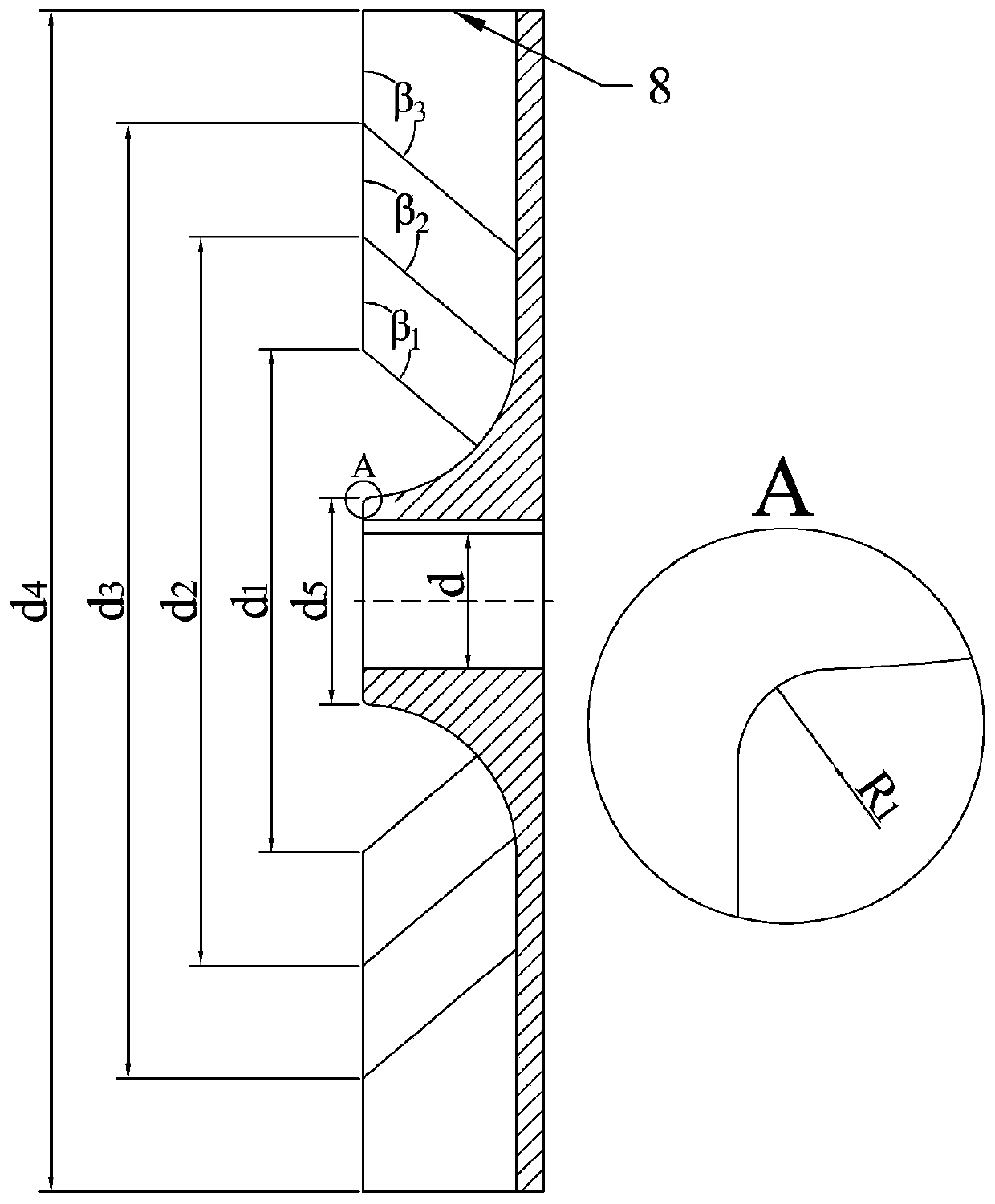

[0036] Such as figure 1 As shown, the optimization object is the impeller of the semi-open impeller centrifugal pump of A1 type, and its rated speed is 2900 rpm. 1 =6, impeller outer diameter d4 =200mm, blade inlet diameter d 1 =85.2mm, inclination angle β at the blade inlet 1 =130°, the blade placement angle α of the outlet 8 of the positive blade surface 9 of the blade 2 Z1 and the blade setting angle α of the outlet 8 of the back blade surface 10 b1 equal and alpha z1 = α b1 =29°, the circumferential blade thickness d of the blade inlet j1 =6.5mm, the circumferential blade thickness d of the blade outlet c1 =14.6mm, the inner diameter of the hub d=23mm, the diameter of the hub at the impeller inlet d 5 = 35mm.

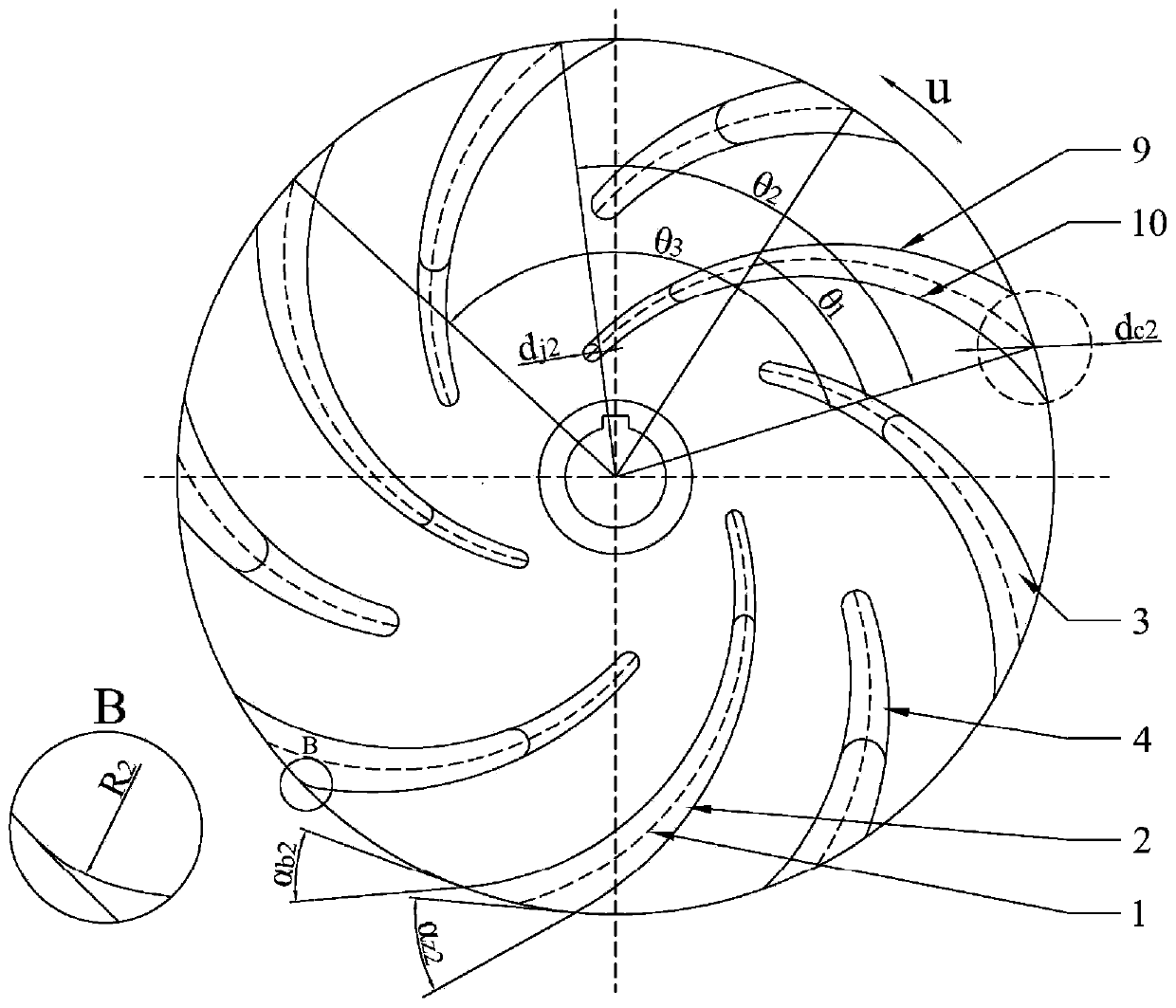

[0037] Such as figure 2 with image 3 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com