Ground source heat pipe self-circulating building cooling and heating system

A self-circulating heat pipe technology, applied in heating systems, heating methods, air-conditioning systems, etc., can solve the problems of environmental pollution and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

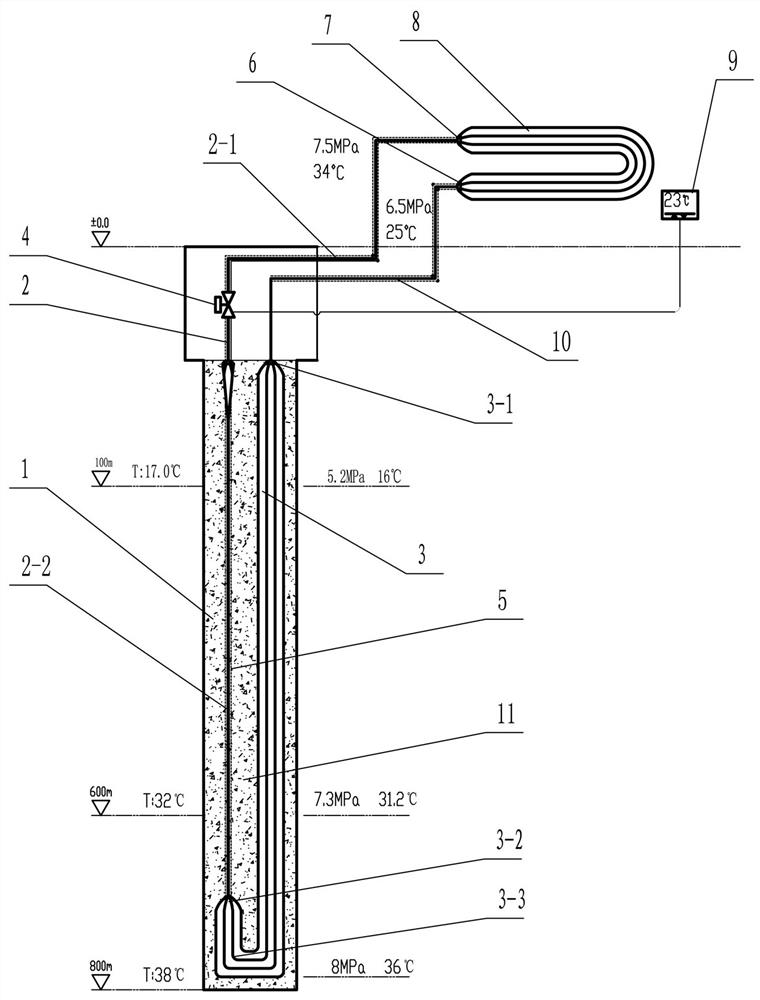

Embodiment 1

[0024] Example 1, such as figure 1As shown, a ground source heat pipe is self-circulating a heating system, which includes a heating circulation line connected to the ground heat exchanger and the underground heat exchanger, and the upper heat exchanger uses a metal indoor capillary 8 in front of the chamber capillary front port and The ports are provided with indoor capillary front port dispenser 6 and the indoor capillary port dispenser 7 for allocating the hydraulic tube. The underground heat exchanger can be used in a multi-set conversant heat transfer tube 3, and the heat transfer tube is disposed in a rock hole 1 in which the temperature layer is 100 meters to kilometers, the heat transfer tube is a U-type heat transfer tube, heat transfer One end of the tube is higher, that is, the heat transfer tube high port 3-1; the other end is low, the heat transfer tube low port 3-2, the height of the heat transfer tube high port is provided in the height of the constant temperature l...

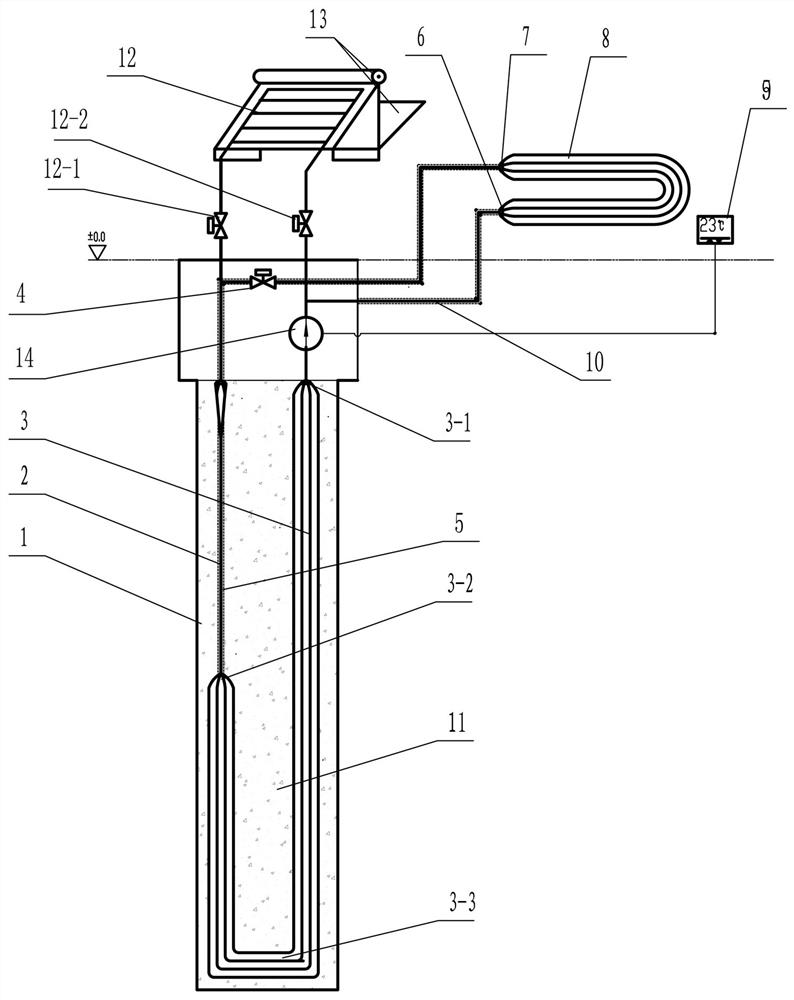

Embodiment 2

[0028] Example 2, such as figure 2 As shown, a ground source heat pipe is self-circulating a heat-warming system, which is made on the basis of the embodiment, which increases the solar collector 12, specifically: in the heating circulation line, with a solar collector plate The solar heat collecting plate front port is connected to the high port leading pipe from the high port, and the port of the solar collector is connected to the low port leading pipe over the low port 2-1, solar collector front port settings There is a solar collector front valve 12-2, and the solar collector rear port is provided with solar collector rear end valve 12-1. A solar collector plate covering the opening joint 13 can also be provided on the solar collector plate, which is provided on the solar collector plate or the back of the heat dissipation opening, or the can be opened as a sunshade. It is also possible to provide a circulating pump in the height port of the heat transfer tube, and a circulat...

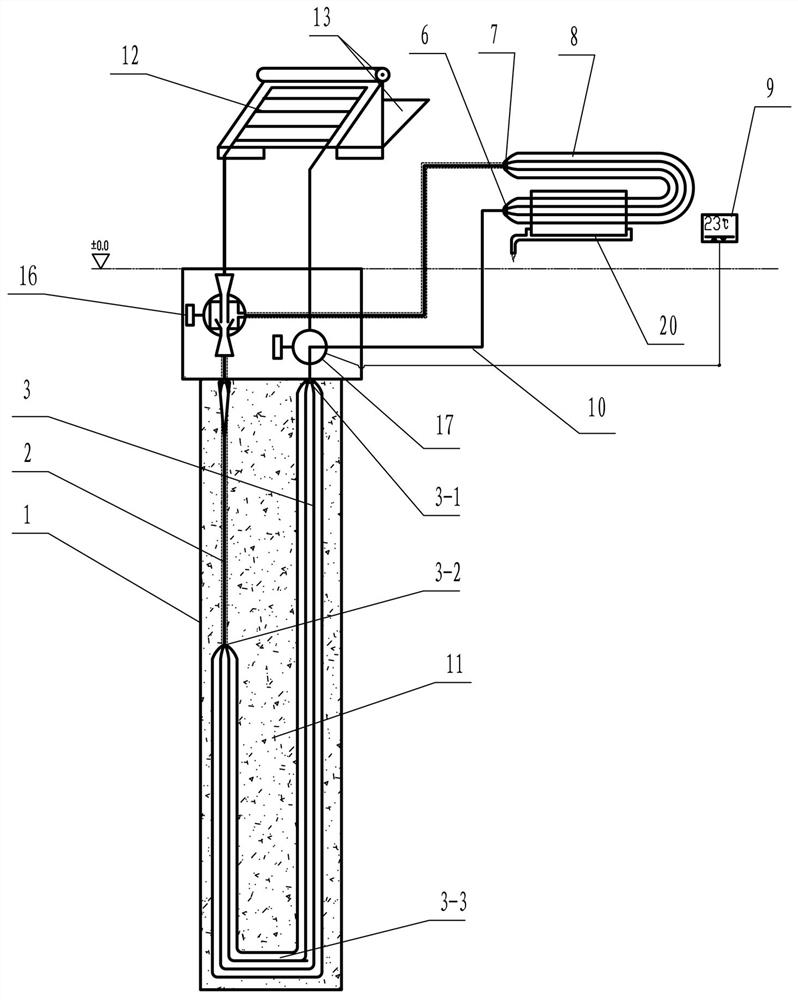

Embodiment 3

[0030] Example 3, image 3 As shown, a ground source heat pipe self-circulating building heating system is further improved on the basis of the second embodiment, the heating circulation line is connected in parallel with solar heat collecting plate 12, increasing the injection three-way valve 16, and a three-way valve 17. The flow branch of the solar collector front port, the high-port leading flow pipe, the upper section 10-1 of the high-port, the lower section 10-2 is connected between the three-way valve 17; another guide after the solar collector The flow tube, the low-port leading flow pipe upper segment 2-1 and the low port leading flow tube are connected between the lower sections 2-2 through the jet three-way valve 16, by setting the three-way valve and the injection three-way valve, the front end of the solar collector plate is replaced. Valves and rear end valves; the solar heat collecting plate can also be provided on the solar collector plate covering the opening and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com