Self-checking method of automatic over-phase control system of motor train unit and realizing circuit

An automatic over-phase and control system technology, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., can solve problems such as failure to maintain and give targeted instructions, failure to accurately locate fault locations, etc. To achieve the effect of saving labor, good detection effect and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

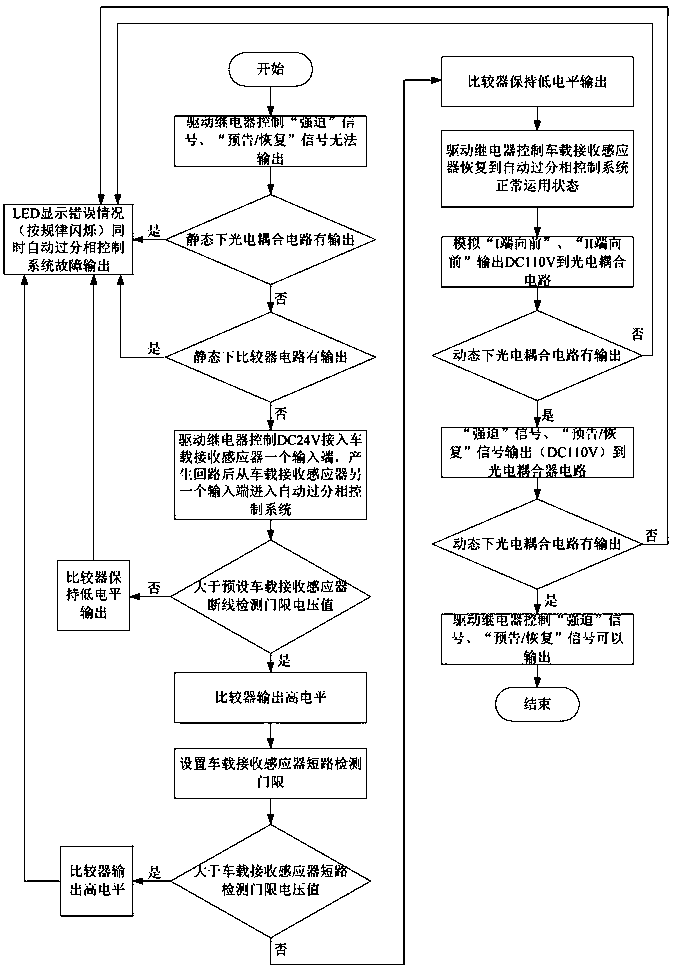

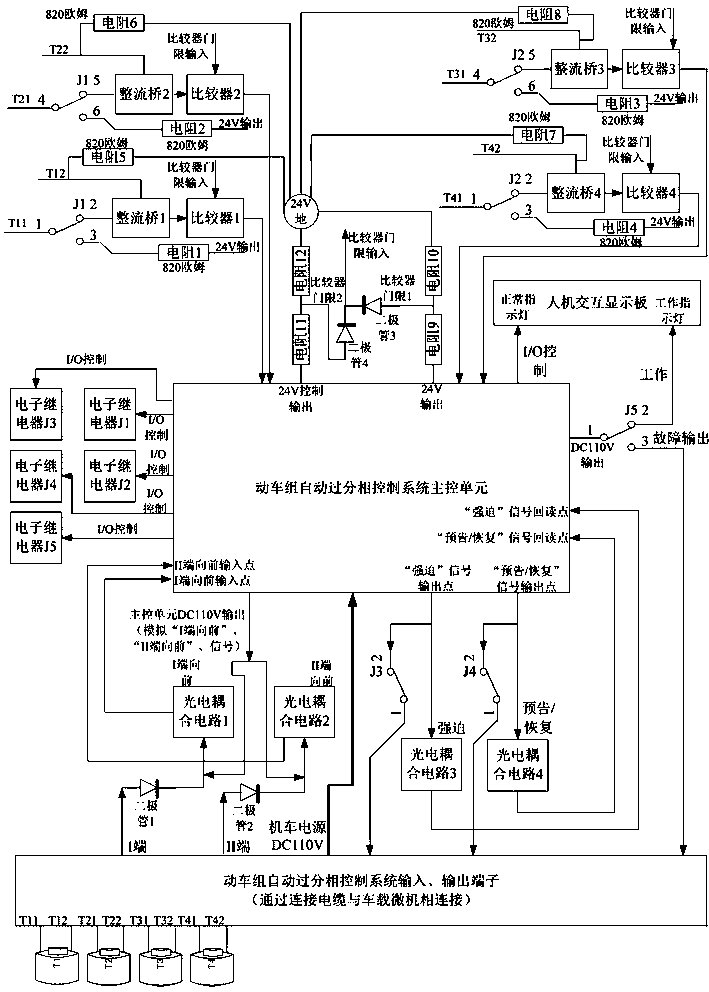

[0027] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the following in conjunction with the attached Figure 1-2 The present invention is described in detail for further specific implementation.

[0028] A self-inspection method of the automatic over-phase separation control system of a multiple train set of the present invention comprises the following steps:

[0029] S1: Start the automatic over-phase control system, the main control unit of the automatic over-phase control system drives the electronic relay used to control whether the "forced" signal and the "prediction / recovery" signal are output to the locomotive control system, so that the normally closed contact is broken. Open to control the output signal of the automatic phase separation control system cannot be output to the locomotive control system;

[0030] S2: Detect whether the photoelectric coupling circuit in the automatic over-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com