Preparation method of new Al4SiC4 layered material

A layered material and a new type of technology, applied in the preparation of new Al4SiC4 layered materials, the field of high-purity new Al4SiC4 layered materials, can solve the problems of difficult machining, poor toughness, high brittleness, etc., to achieve widespread application value, technology Simple process and high purity results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

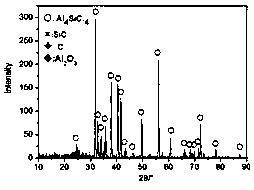

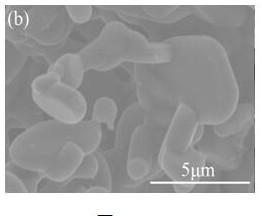

Embodiment 1

[0039] Using Al(OH) 3 , SiO 2 Provide Al, Si, and C elements with phenolic resin as raw materials, and use the chemical precursor method to synthesize the layered material Al 4 SiC 4 . Firstly, the method of measuring the carbon content in the phenolic resin is as follows: after dissolving a certain amount of phenolic resin in alcohol, put it in a 40°C drying oven to dry to obtain the phenolic resin colloid. Then, put the phenolic resin colloid into a vacuum drying oven heated at the bottom to fully dry and evaporate excess alcohol. Finally, put the dried powder into a multifunctional furnace and keep it warm at 1000°C for 1 hour. The ratio of the obtained carbon powder to the mass of the original phenolic resin is the carbon content of the phenolic resin. After measuring the carbon ratio of the phenolic resin, the powder is mixed, and the molar ratio is Al 2 o 3 :SiO2 2 :C=2:2:12. Put the mixed original powder into alcohol and wet mix it for 24 hours, then dry it in a...

Embodiment 2

[0041] Using Al(OH) 3 , SiO 2 Provide Al, Si, and C elements with phenolic resin as raw materials, and use the chemical precursor method to synthesize the layered material Al 4 SiC 4 . Firstly, the method of measuring the carbon content in the phenolic resin is as follows: after dissolving a certain amount of phenolic resin in alcohol, put it in a drying oven at 50°C to dry to obtain the phenolic resin colloid. Then, put the phenolic resin colloid into a vacuum drying oven heated at the bottom to fully dry and evaporate excess alcohol. Finally, put the dried powder into a multifunctional furnace and keep it warm at 900°C for 1 hour. The ratio of the obtained carbon powder to the mass of the original phenolic resin is the carbon content of the phenolic resin. After measuring the carbon ratio of the phenolic resin, the powder is mixed, and the molar ratio is Al 2 o 3 :SiO2 2 :C=2:1:13. Put the mixed original powder into alcohol and wet mix it for 24 hours, then dry it in...

Embodiment 3

[0043] Using Al(OH) 3 , SiO 2 Provide Al, Si, and C elements with phenolic resin as raw materials, and use the chemical precursor method to synthesize the layered material Al 4 SiC 4 . Firstly, the method of measuring the carbon content in the phenolic resin is as follows: after dissolving a certain amount of phenolic resin in alcohol, put it in a drying oven at 50°C to dry to obtain the phenolic resin colloid. Then, put the phenolic resin colloid into a vacuum drying oven heated at the bottom to fully dry and evaporate excess alcohol. Finally, put the dried powder into a multifunctional furnace and keep it warm at 1000°C for 1 hour. The ratio of the obtained carbon powder to the mass of the original phenolic resin is the carbon content of the phenolic resin. After measuring the carbon ratio of the phenolic resin, the powder is mixed, and the molar ratio is Al 2 o 3 :SiO2 2 :C=2:1:10. Put the mixed original powder into alcohol and wet mix it for 24 hours, then dry it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com