Method for preparing large yellow croaker defatted fish egg protein emulsifier by enzymatic modification

A technology of fish egg protein and large yellow croaker, which can be used in food ingredients as emulsifiers, protein-containing food ingredients, and bulk chemical production, etc. It can solve problems such as poor solubility, weak emulsification, and no discovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

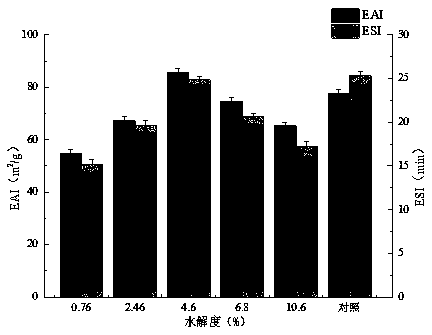

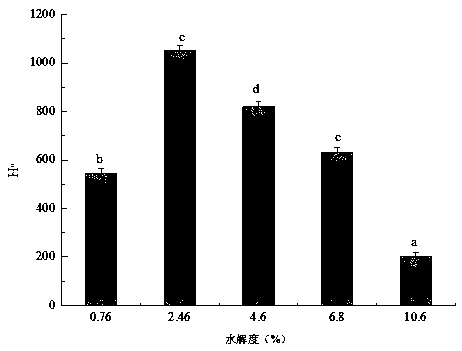

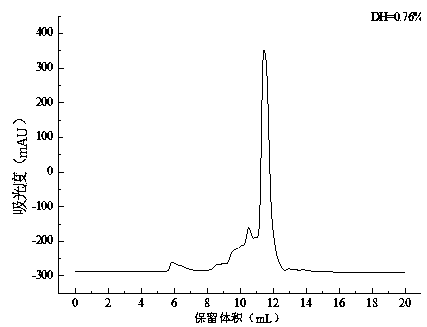

[0016] Weigh 1 kg of large yellow croaker defatted fish egg protein powder, add 10 kg of 0.01mol / L phosphate buffer solution with a pH of 6.5, and prepare large yellow croaker defatted fish egg protein powder with a material-to-liquid ratio (kg / kg) of 1:10 Dispersions. Add papain so that each gram of large yellow croaker defatted fish egg protein powder corresponds to 10,000 units of enzyme activity, stir well, adjust the pH to 6.5 with 0.1mol / L sodium hydroxide, and then place it in an enzymatic hydrolysis tank at a constant temperature of 55°C until the protein is hydrolyzed After the degree of hydrolysis reached 4.6%, the enzymolysis solution was heated to 85°C for 15 minutes to inactivate the activity of the enzyme, then cooled in an ice-water bath and centrifuged at 4°C and 5000 rpm / min for 15 minutes in a refrigerated centrifuge, and the supernatant was collected. The large yellow croaker defatted egg protein emulsifier was prepared after the supernatant was vacuum freez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com