Novel dialysis tube used for hemodialysis equipment

A hemodialysis and dialysis tube technology, applied in the field of new dialysis tubes, can solve the problems of slow dialysis efficiency, increase in medical waste, and slow dialysis efficiency, and achieve the effect of heating up, simple overall structure, and avoiding discomfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

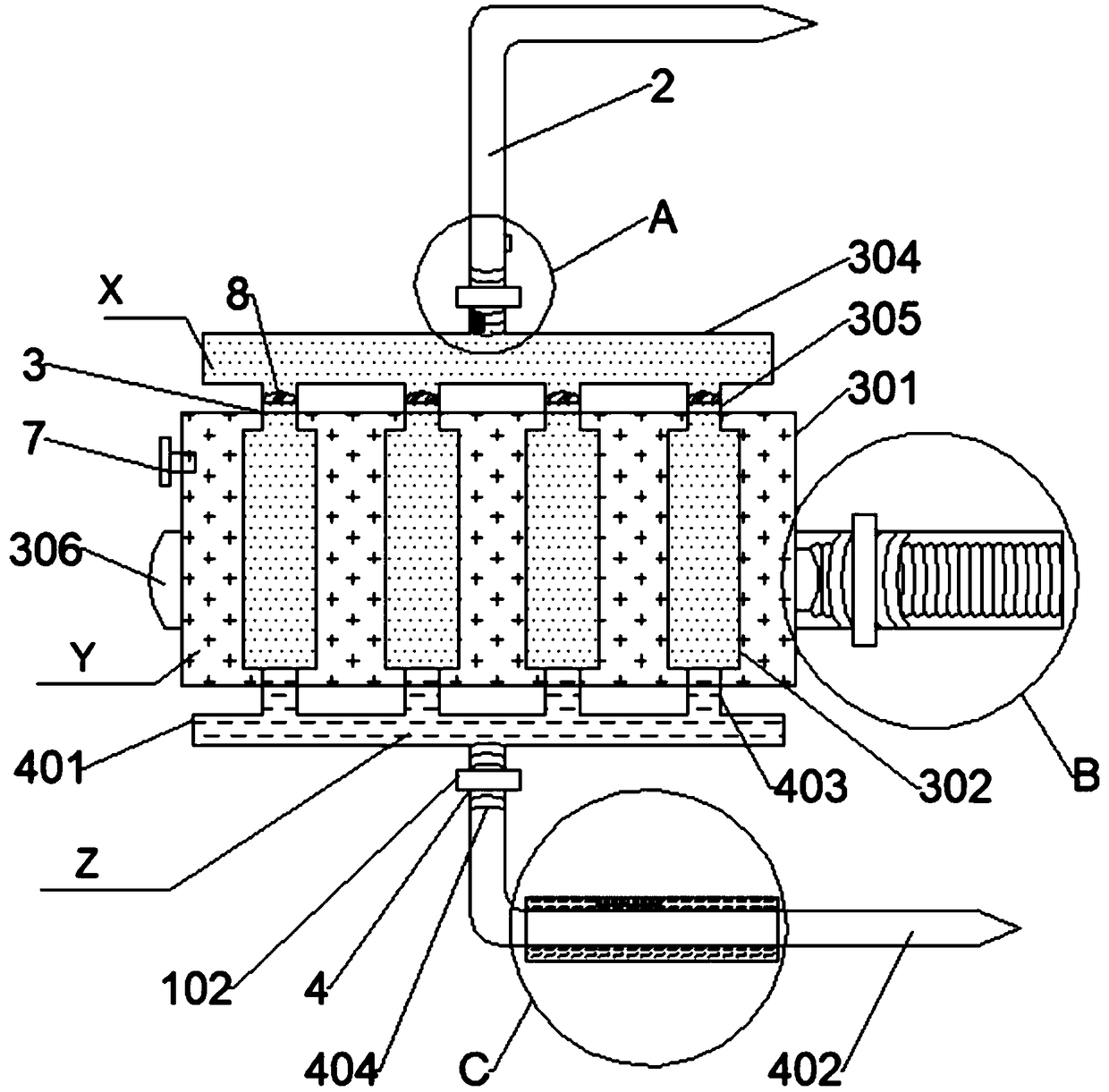

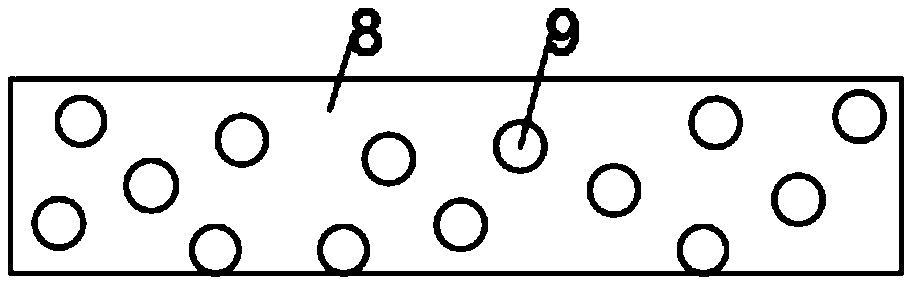

[0042] Such as Figure 1 to Figure 7As shown, the present invention provides a new type of dialysis tubing for hemodialysis equipment, including a dialysis control device 1 and a dialysis needle tube 2 for drawing blood from the patient's body. When performing dialysis operations, the dialysis needle tube 2 is inserted into the patient's artery Inside, one end of the dialysis needle tube 2 is provided with a hemodialysis device 3, and the hemodialysis device 3 is respectively connected with a blood return device 4 for retransporting the dialysis-purified blood to the patient's body and a blood return device 4 for separating and discharging the blood after dialysis to produce dialysis. Mass liquid sorting mechanism 5 of waste.

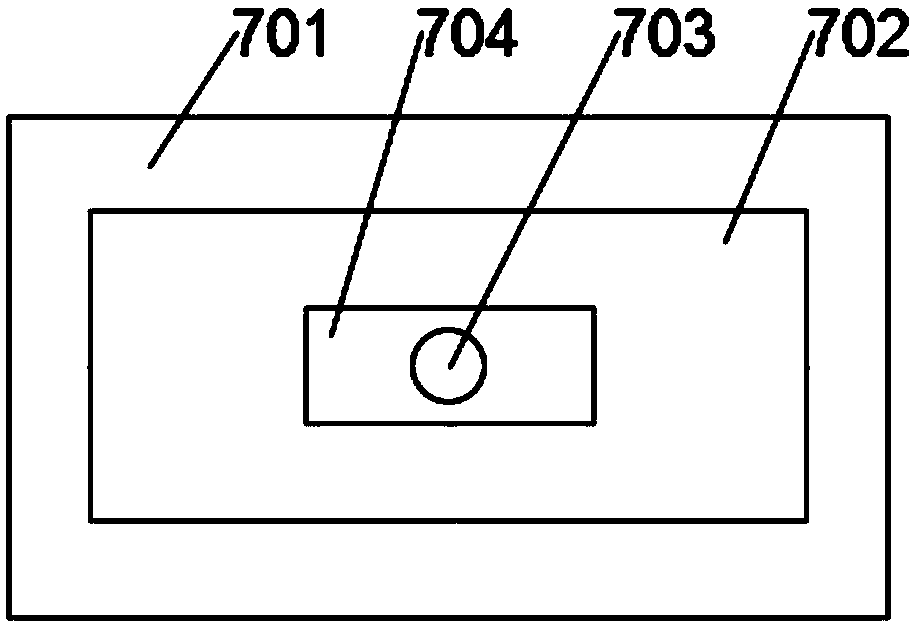

[0043] The hemodialysis device 3 includes a dialysis bag 301 filled with dialysate and several fibrous dialysis membranes 302 in a tubular structure, the fibrous dialysis membranes 302 are arranged in the dialysis bag 301, and the arrangement of a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com