PMIA super-hydrophobic nano-fiber membrane for oil water separation and preparation method thereof

A nanofiber membrane, oil-water separation technology, applied in separation methods, liquid separation, semi-permeable membrane separation, etc., can solve the problems of poor hydrophobicity of oil-water separation nanofiber membranes, the oil-water separation efficiency needs to be improved, and the oil-water separation efficiency is low. Achieve good mechanical properties, good hydrophobicity, and improve the effect of hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

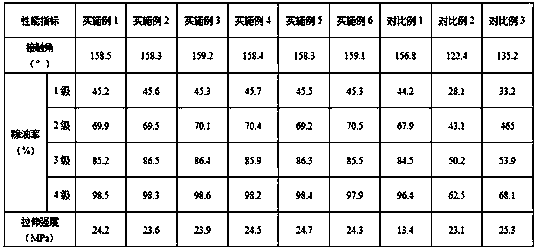

Examples

Embodiment 1

[0034] (1) Add poly-m-phenylene isophthalamide and lithium chloride to N,N-dimethylacetamide, stir until completely dissolved, then add polyethylene glycol, heat and stir evenly, after vacuum deaeration Inject into the electrospinning device and perform electrospinning to prepare PMIA nanofiber membrane; the electrospinning voltage is 14kV, the receiving distance is 16cm, and the spinning hole diameter is 300nm; the weight of each raw material is polyisoxylene 13 parts by weight of metaphenylene diamine, 4 parts by weight of lithium chloride, 76 parts by weight of N,N-dimethylacetamide, and 7 parts by weight of polyethylene glycol;

[0035] (2) Pretreat the nanofiber membrane prepared in step (1) with fluorine-containing alkyl silane, add aniline hydrochloride and titanium dioxide into water to disperse uniformly to make a mixed solution, and then spray and deposit the mixed solution on the pretreated nanofiber The surface of the film is subjected to oxidative polymerization unde...

Embodiment 2

[0039] (1) Add poly-m-phenylene isophthalamide and lithium chloride to N,N-dimethylacetamide, stir until completely dissolved, then add polyethylene glycol, heat and stir evenly, after vacuum deaeration Inject into the electrospinning device and perform electrospinning to prepare PMIA nanofiber membrane; the electrospinning voltage is 13kV, the receiving distance is 16cm, and the spinning hole diameter is 300nm; the weight of each raw material is polyisoxylene 13 parts by weight of metaphenylene diamine, 3 parts by weight of lithium chloride, 78 parts by weight of N,N-dimethylacetamide, and 6 parts by weight of polyethylene glycol;

[0040] (2) Pretreat the nanofiber membrane prepared in step (1) with fluorine-containing alkyl silane, add aniline hydrochloride and titanium dioxide into water to disperse uniformly to make a mixed solution, and then spray and deposit the mixed solution on the pretreated nanofiber The surface of the film is oxidized and polymerized under ultraviolet...

Embodiment 3

[0044] (1) Add poly-m-phenylene isophthalamide and lithium chloride to N,N-dimethylacetamide, stir until completely dissolved, then add polyethylene glycol, heat and stir evenly, after vacuum deaeration Inject into the electrospinning device and perform electrospinning to prepare PMIA nanofiber membrane; the electrospinning voltage is 17kV, the receiving distance is 17cm, and the spinning hole diameter is 400nm; the weight of each raw material is polyisoxylene 15 parts by weight of metaphenylene diamine, 5 parts by weight of lithium chloride, 72 parts by weight of N,N-dimethylacetamide, and 8 parts by weight of polyethylene glycol;

[0045] (2) Pretreat the nanofiber membrane prepared in step (1) with fluorine-containing alkyl silane, add aniline hydrochloride and titanium dioxide into water to disperse uniformly to make a mixed solution, and then spray and deposit the mixed solution on the pretreated nanofiber The surface of the film is oxidized and polymerized under ultraviolet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com