Catalyst for catalytic oxidation of formaldehyde at room temperature and preparation method thereof

A catalytic oxidation and catalyst technology, which is applied in the fields of catalyst materials, environmental catalysis and environmental protection, can solve the problems of human health hazards and long volatilization period, and achieve the effect of low cost, easy operation and long-term activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

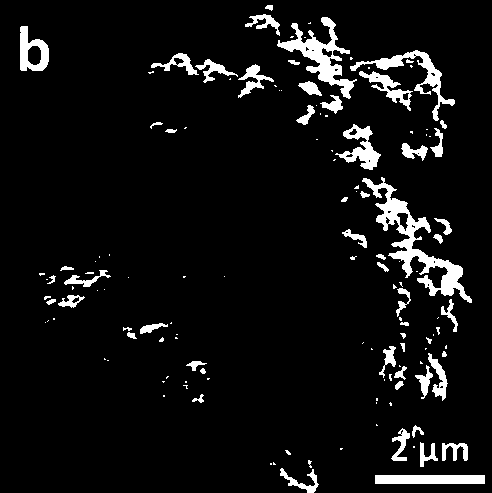

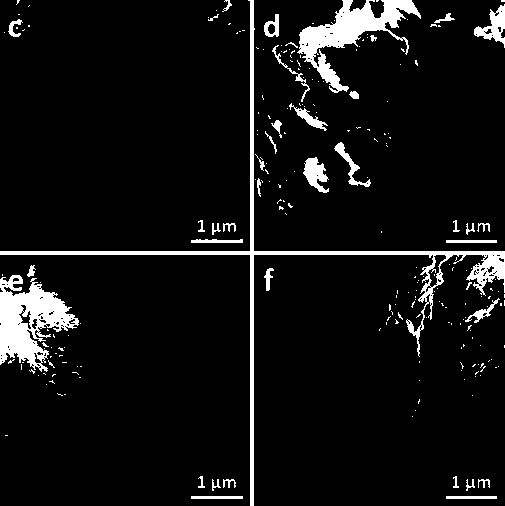

Image

Examples

Embodiment 1

[0028] A simple preparation method of nano-sheet AlOOH, the steps are as follows:

[0029] 1) Measure 100 ml of cyclohexane and 20.5 g of PEG (polyethylene glycol), mix them in a beaker, stir at room temperature for 10-20 minutes, and rotate at 900-1000 rpm;

[0030] 2) Weigh 2.016 g Al(NO 3 ) 3 ·9H 2 O, add deionized water and dissolve to 20 ml to obtain Al(NO 3 ) 3 Solution

[0031] 3) Slowly add the solution obtained in step 2) to the mixture described in step 1), and then stir at room temperature for 10-20 minutes at 900-1000 rpm;

[0032] 4) In the solution obtained in step 3), add 3.85 ml of concentrated ammonia water dropwise, the solution begins to appear white precipitation, keep stirring at room temperature for more than 2 hours, rotating speed 900-1000rpm;

[0033] 5) Centrifuge the solution obtained in step 4) at 2000-2500 rpm for 3-5 min. After centrifugation, take the precipitate, add deionized water for cleaning, centrifuge again, and repeat the centrifugal cleaning step ...

Embodiment 2

[0037] A kind of AlOOH / MnO 2 The composite catalyst and its preparation method, the preparation steps are as follows:

[0038] 1) Measure 100 ml of cyclohexane and 20.5 g of PEG (polyethylene glycol), mix them in a beaker, stir at room temperature for 10-20 minutes, and rotate at 900-1000 rpm;

[0039] 2) Weigh 2.016 g Al(NO 3 ) 3 ·9H 2 O, add deionized water and dissolve to 20 ml to obtain Al(NO 3 ) 3 Solution

[0040] 3) Slowly add the solution obtained in step 2) to the mixture described in step 1), and then stir at room temperature for 10-20 minutes at 900-1000 rpm;

[0041] 4) In the solution obtained in step 3), add 3.85 ml of concentrated ammonia water dropwise, the solution starts to appear white precipitation, keep stirring at room temperature for more than 2 hours, the speed is 900-1000 rpm;

[0042] 5) Centrifuge the solution obtained in step 4) at 2000-2500 rpm for 3-5 min. After centrifugation, take the precipitate, add deionized water for cleaning, centrifuge again, and re...

Embodiment 3

[0052] The AlOOH and MnO generated on the surface of the metal Al mesh 2 The composite catalyst and its preparation method, the preparation steps are as follows:

[0053] 1) At room temperature, immerse the metal Al mesh in a 0.1 wt% NaOH solution for 2 minutes to remove the surface alumina layer, and then rinse with deionized water;

[0054] 2) Put the treated metal Al mesh in a hydrothermal kettle, add deionized water, and heat to 120°C for 2 hours to generate AlOOH on the surface of the Al mesh;

[0055] 3) Immerse the Al mesh with AlOOH on the surface described in step 2) in 0.1 M KMnO 4 In the solution for more than 12 hours, AlOOH / MnO is formed on the surface 2 The composite is rinsed with deionized water and dried at room temperature to obtain AlOOH / MnO attached to the surface of the metal Al mesh 2 Composite catalyst material.

[0056] The catalyst prepared in this example combines AlOOH and MnO generated on the surface of the metal Al mesh 2 Composite, due to the existence of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com