Waste material collection device for machining of guide rod of road marker

A waste collection and guide rod technology, which is applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems affecting waste collection and blockage, and achieve the effect of reducing labor intensity, avoiding pollution, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

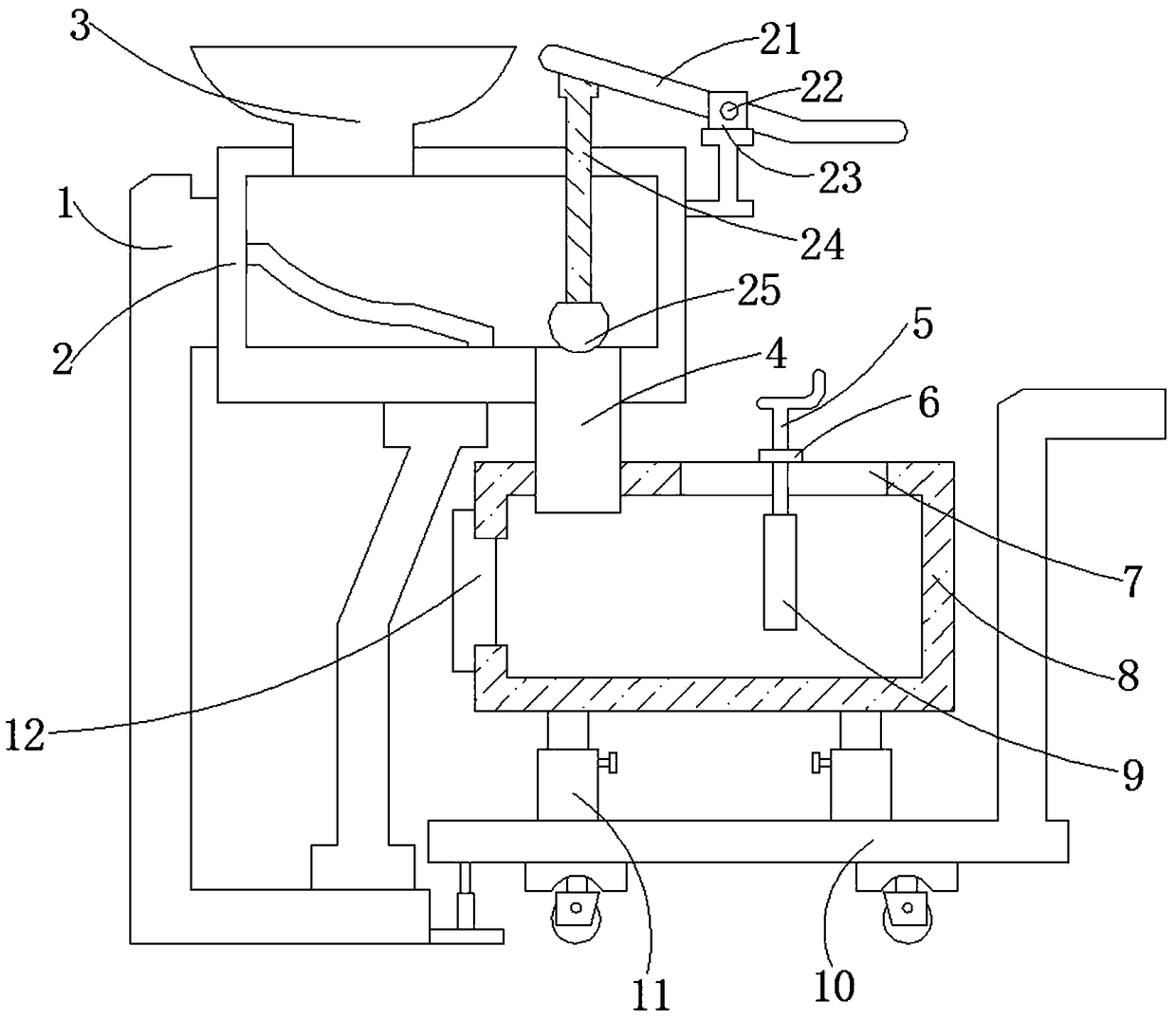

[0023] Embodiment 1: When using the collection device to collect the waste generated by the processing of the guide rod, it is necessary to place the entire device on the lower side of the processing device close to the guide rod, so that the waste generated during the processing passes through the feed channel 3 , transported to the inside of the collection box 2, and under the action of the guide plate provided in the collection box 2, the waste falling into the collection box 2 can slide down to the inside of the delivery channel 4, and through the transmission of the delivery channel 4, it can Let the waste fall into the interior of the recovery box 8, and collect the waste generated during the processing of the guide rod, which avoids the pollution of the processing environment caused by the waste generated during the processing, and also saves the time for manual cleaning of the waste, and reduces the waste disposal. labor intensity.

Embodiment 2

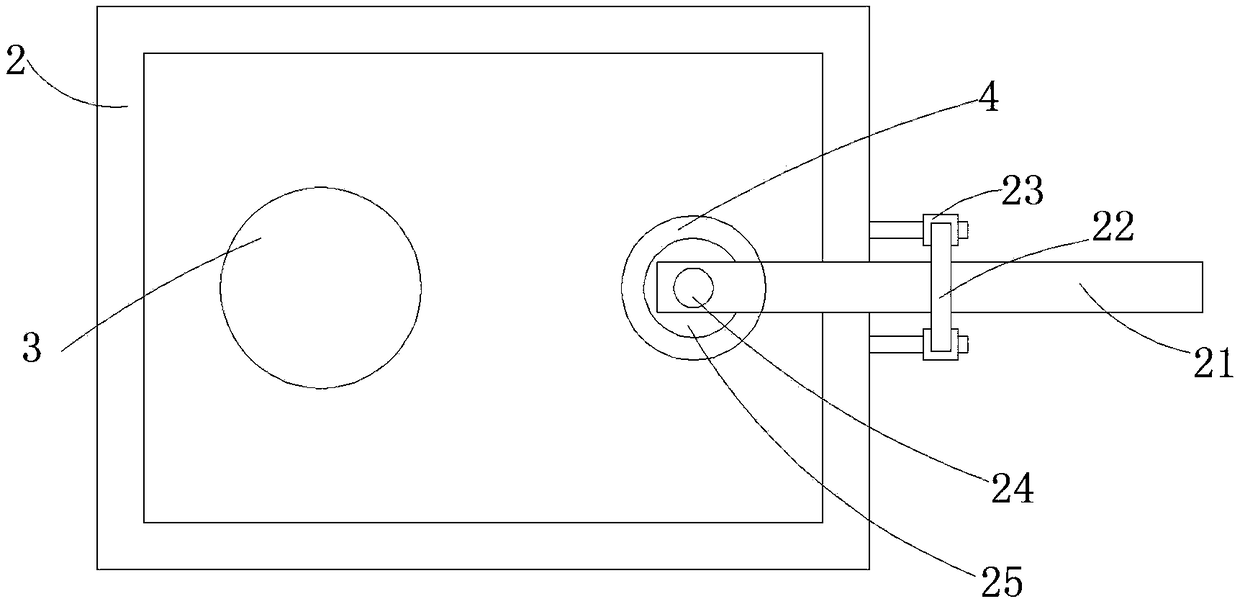

[0024] Embodiment 2: In the process that the waste material generated by the guide rod processing continuously falls into the collection box 2, the waste material blockage may occur in the conveying channel 4. At this time, the first connecting rod 21 is manually held, and the first connecting rod 21 is wound The fixed rod 22 pushes up and down, and when the first connecting rod 21 is pushed, it will drive the second connecting rod 24 to move up and down in the collection box 2, and the piston block 25 moves up and down in the conveying channel 4. The conveying movement in the direction pushes the waste materials near the conveying channel 4, avoiding the clogging phenomenon when the conveying channel 4 transports waste materials, and improving the service life of the waste material collecting device.

Embodiment 3

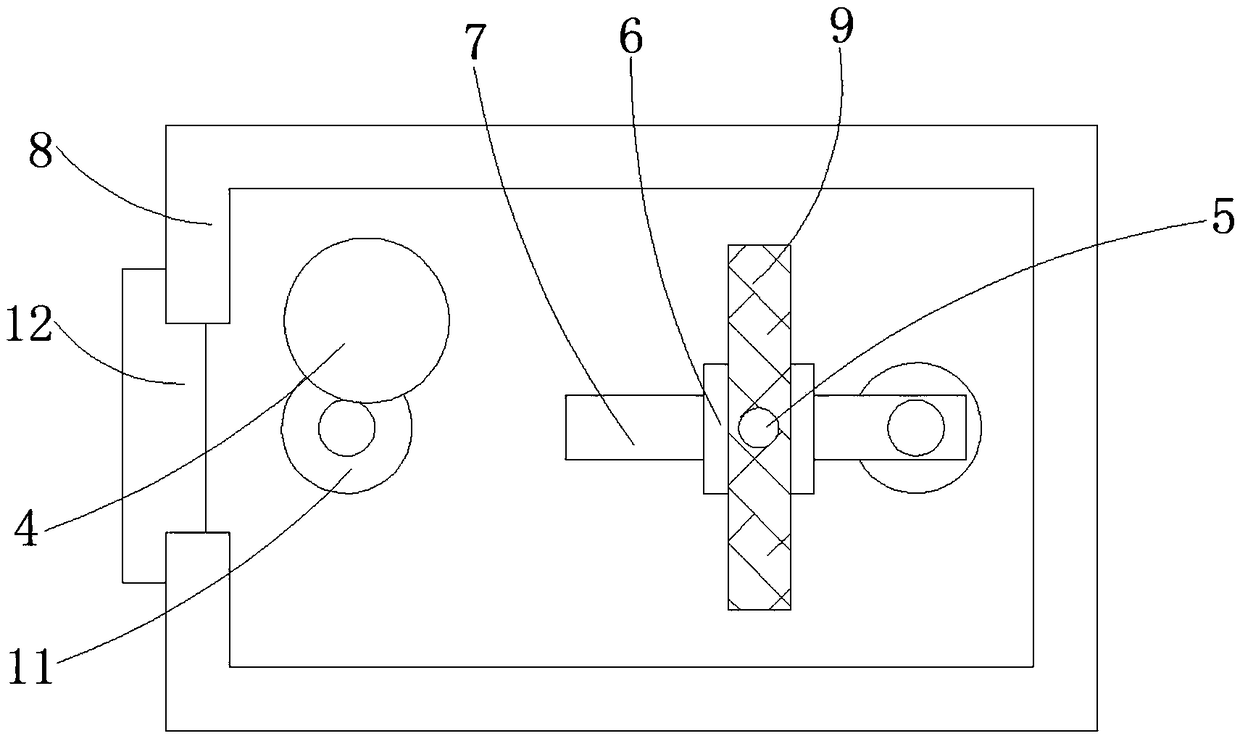

[0025] Embodiment 3: When the amount of waste collected in the recovery box 8 is gradually increasing, the movable push rod 5 can be manually held at this time, so that the movable push rod 5 can pull the linkage push plate 9, so that the position of the linkage push plate 9 can be adjusted. Increase the height, and hold the movable push rod 5 to make the interlocking push plate 9 obliquely set, and the interlocking push plate 9 will obliquely scrape the waste near the side of the conveying channel 4 to the side away from the conveying channel 4. The push plate 9 stacks waste materials in the recovery box 8, which improves the utilization rate of the space in the recovery box 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com