Intelligent automatic control system for film lamination machine

A technology of automatic control system and laminating machine, applied in control/adjustment system, non-electric variable control, simultaneous control of multiple variables, etc., can solve the problems of low quality of lamination, difficult control of lamination operation, etc., to improve work efficiency Efficiency, easy control, effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] An intelligent automatic control system for a laminating machine according to the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

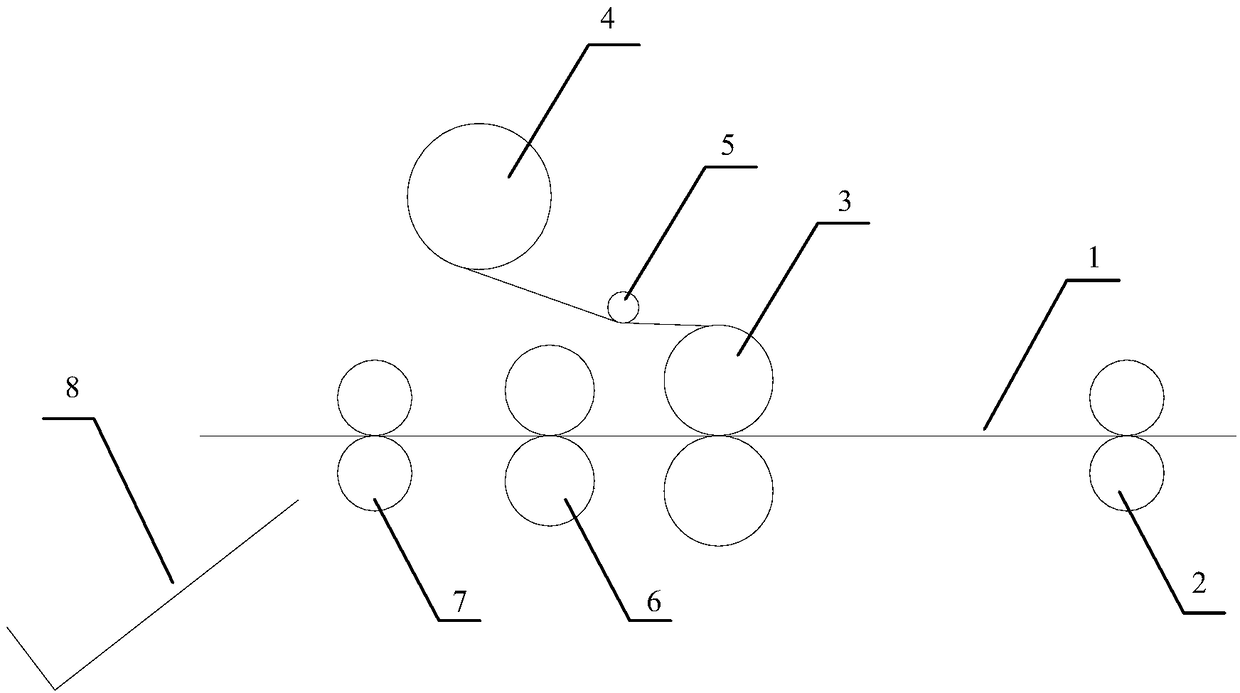

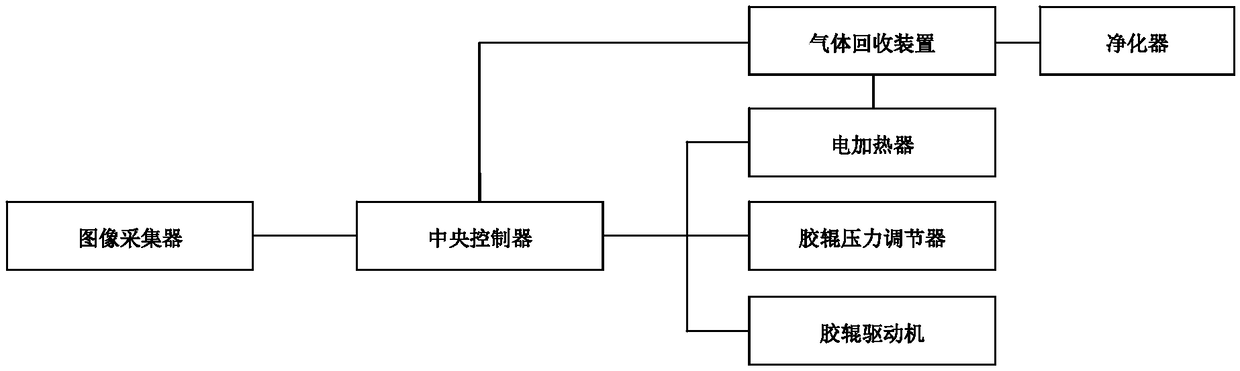

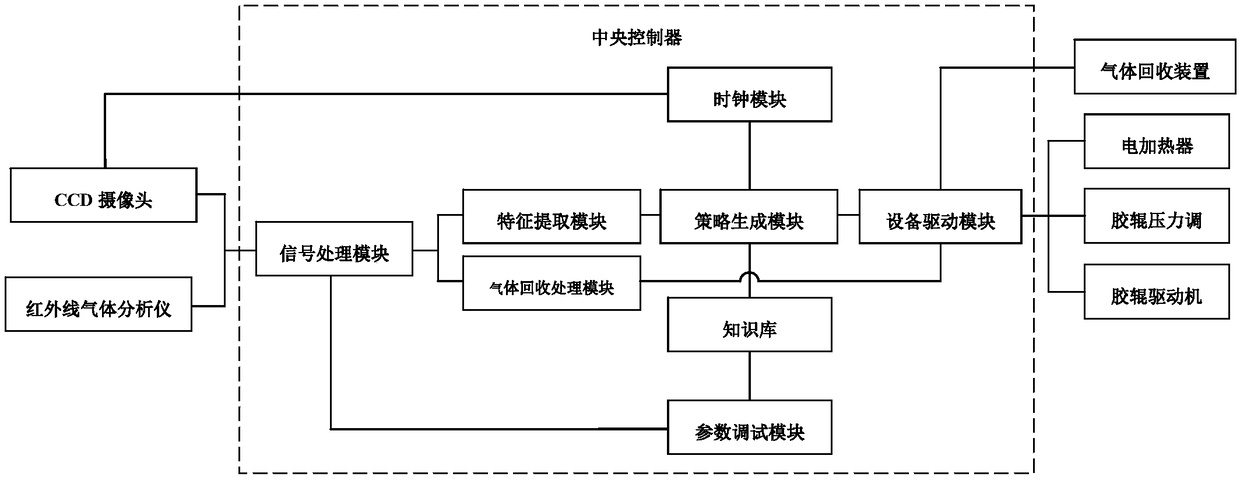

[0031] Such as figure 1 , 2As shown, an intelligent automatic control system for a laminating machine provided by the present invention includes: an image collector, a central controller, an electric heater, a rubber roller pressure regulator and a rubber roller driver, a gas monitor, a gas recovery device and purifier; the image collector is used to collect the image of the film-coated sample and send it to the central controller, and the gas monitor and gas recovery device are arranged on the electric heater where harmful gas is generated The monitor is used to monitor the components of the harmful gas and the concentration of each component, and generate component data and concentration data. The gas recovery device is used to collect the harmful gas and send it to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com