Method for preparing high sodium carbonate type lead carbonate by utilizing lead-containing fly ash

A technology of lead carbonate and soda ash, which is applied in the direction of lead carbonate, etc., can solve the problems of product purity and related standards that are not specified, and achieve the effects of expanding comprehensive utilization channels, high leaching rate, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

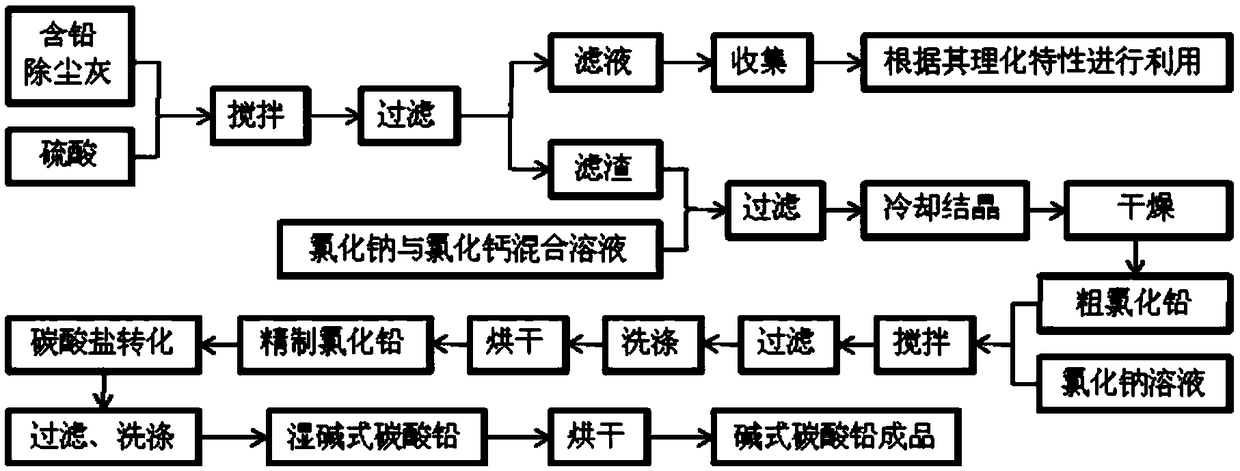

Method used

Image

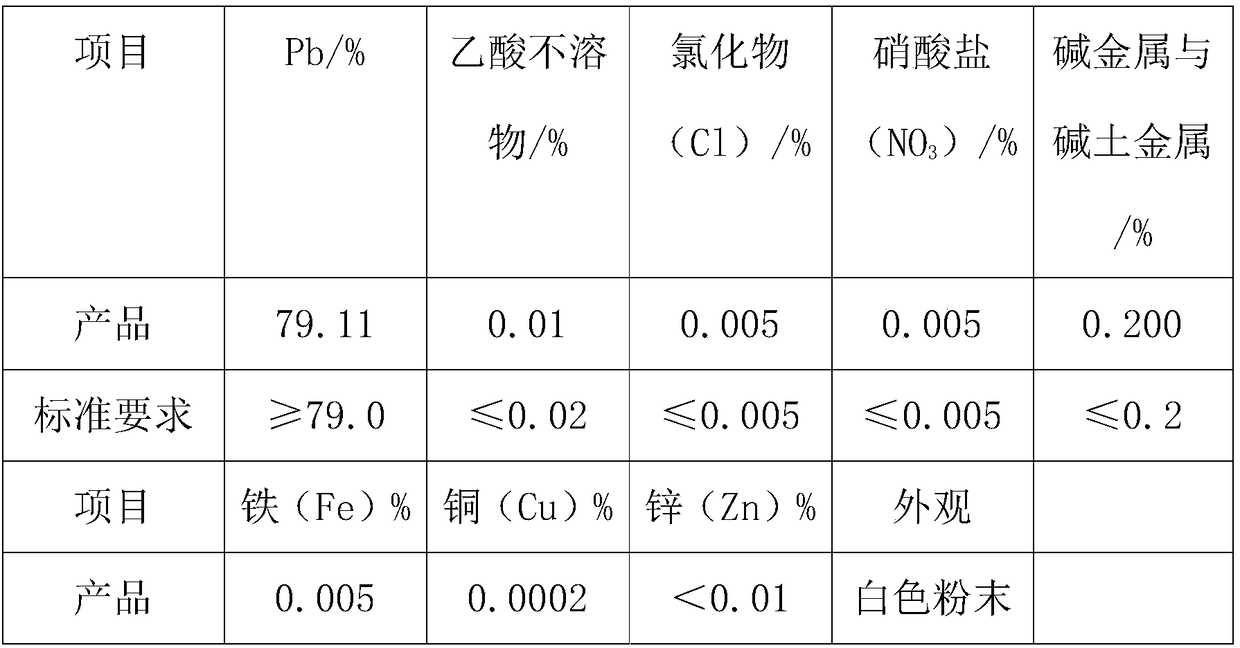

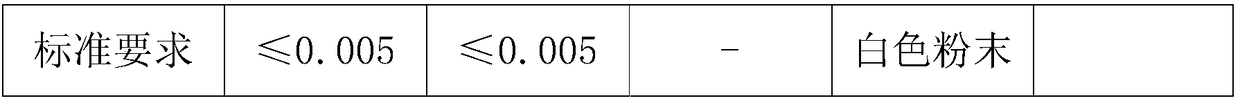

Examples

Embodiment 1

[0035] A kind of method that utilizes lead-containing dedusting ash to produce high purity lead carbonate, comprises the following steps:

[0036] 1), the main components and particle size distribution of the lead-containing dust removal ash used are shown in Table 1 and Table 2. Take 200g of lead-containing dust removal dust and add it to 700mL of sulfuric acid solution with a concentration of 150g / L, heat it to 65°C and keep it warm. Then stir and react for 30 minutes under the condition of stirring at 300r / min. After the reaction is complete, filter, collect the filtrate and filter residue respectively, dry the filter residue at 110°C, and analyze the chemical composition. The test results are shown in Table 3;

[0037] 2), preparation concentration is 200mL of sodium chloride solution of 180g / L, adds 12g industrial calcium chloride in the prepared sodium chloride solution, it is mixed with sodium chloride and calcium chloride mixed solution, will prepare Put the mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com