Sole material and method for manufacturing wet anti-slip sole

A technology of sole material and rubber material, which is applied in the field of shoe manufacturing, can solve problems such as poor wear resistance, failure to meet the needs of sports products, and failure to balance anti-slip and wear resistance, etc., to achieve strong grip and excellent rubber wetness The effect of anti-slip characteristics and excellent flexural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

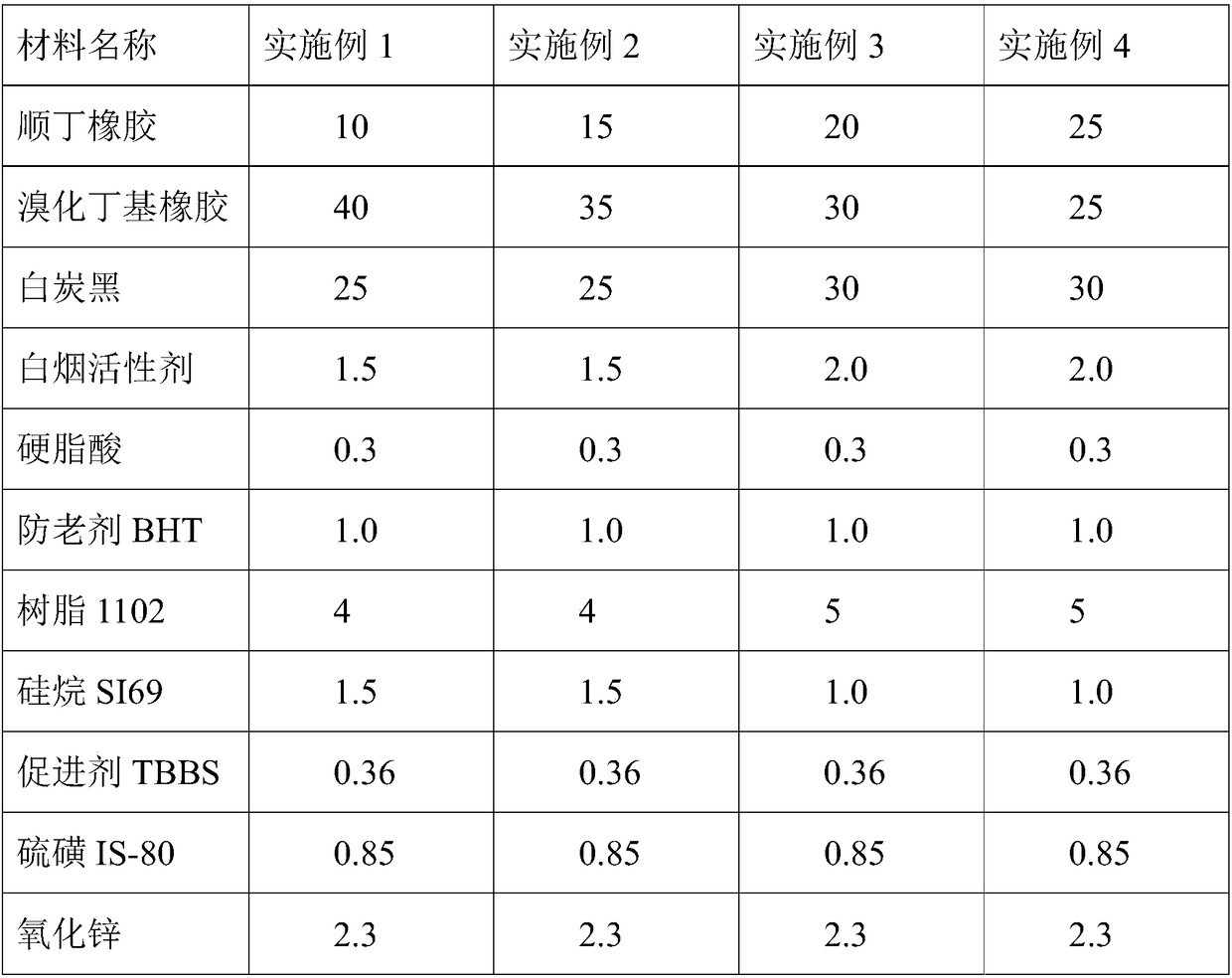

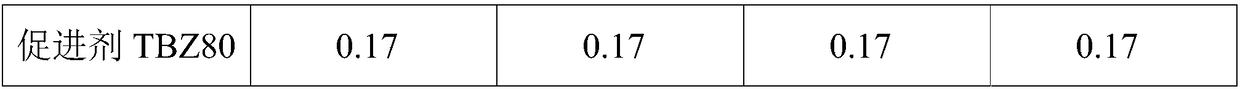

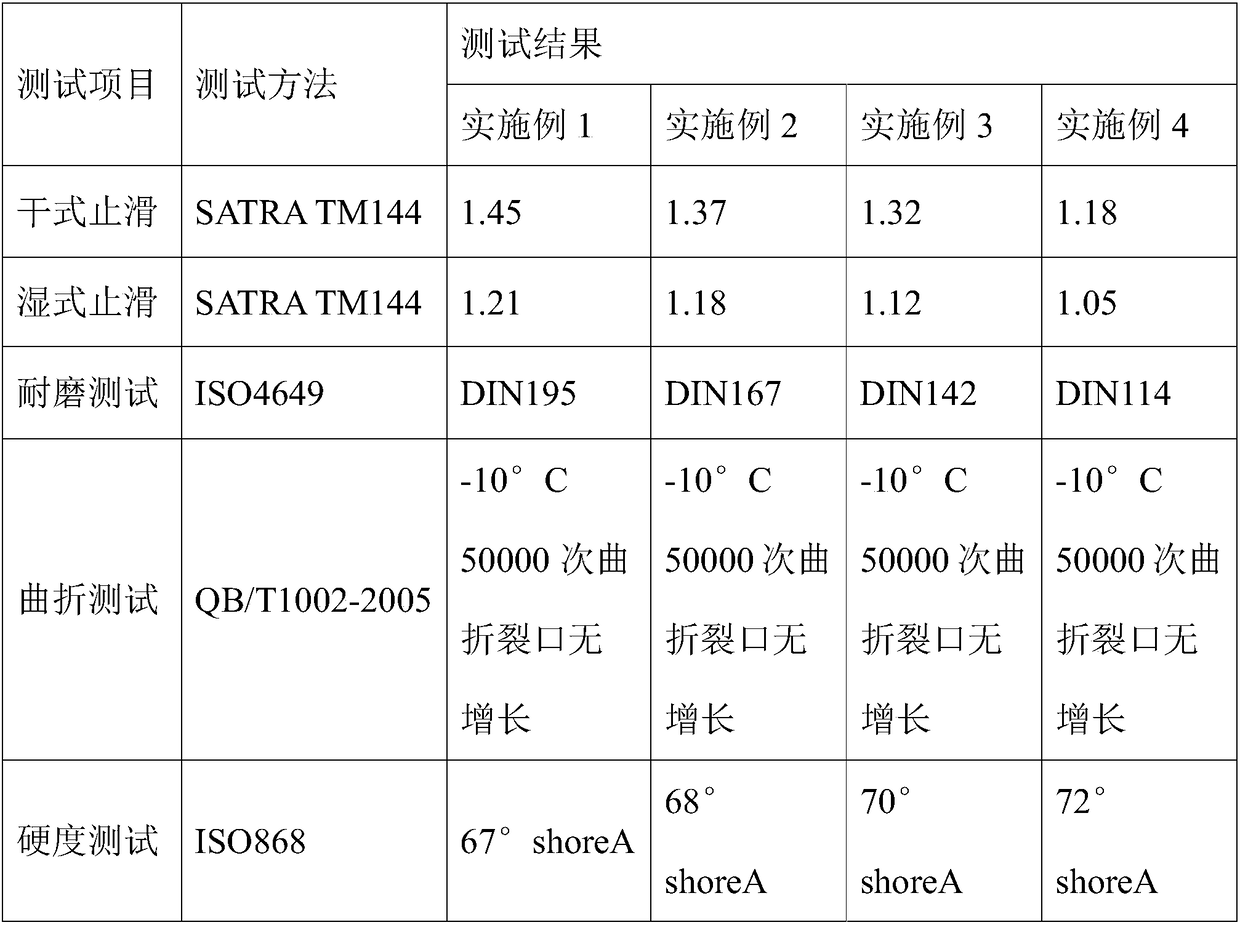

[0021]

[0022]

[0023] A method for making wet anti-slip soles, using the sole material of any one of the above-mentioned specific embodiments, comprising the following steps:

[0024] The above-mentioned various components are prepared according to the above-mentioned mass parts ratio, and the butadiene rubber, bromobutyl rubber, white carbon black, stearic acid, anti-aging agent, white smoke active agent, accelerator, silane coupling agent and resin After mixing in the internal mixer to 120°C, unload, cool in water, store and mature; then refine the rubber material through an open mill, add the sulfur, accelerator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com