Efficient VCP copper-plating brightening agent

A technology of brightener and copper plating, which is applied in the field of brightener, can solve problems such as inability to meet PCB manufacturing requirements, and achieve the effects of excellent deep plating ability, excellent throwing ability, and no stress on the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

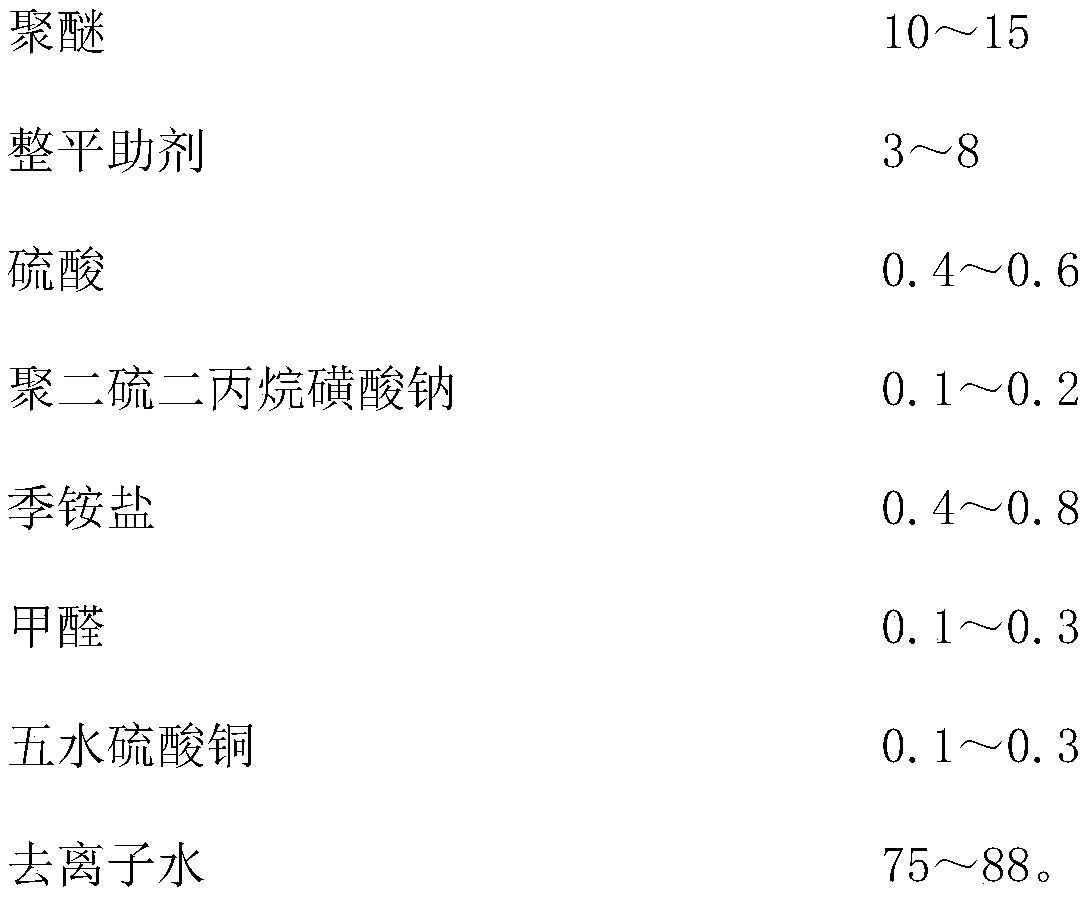

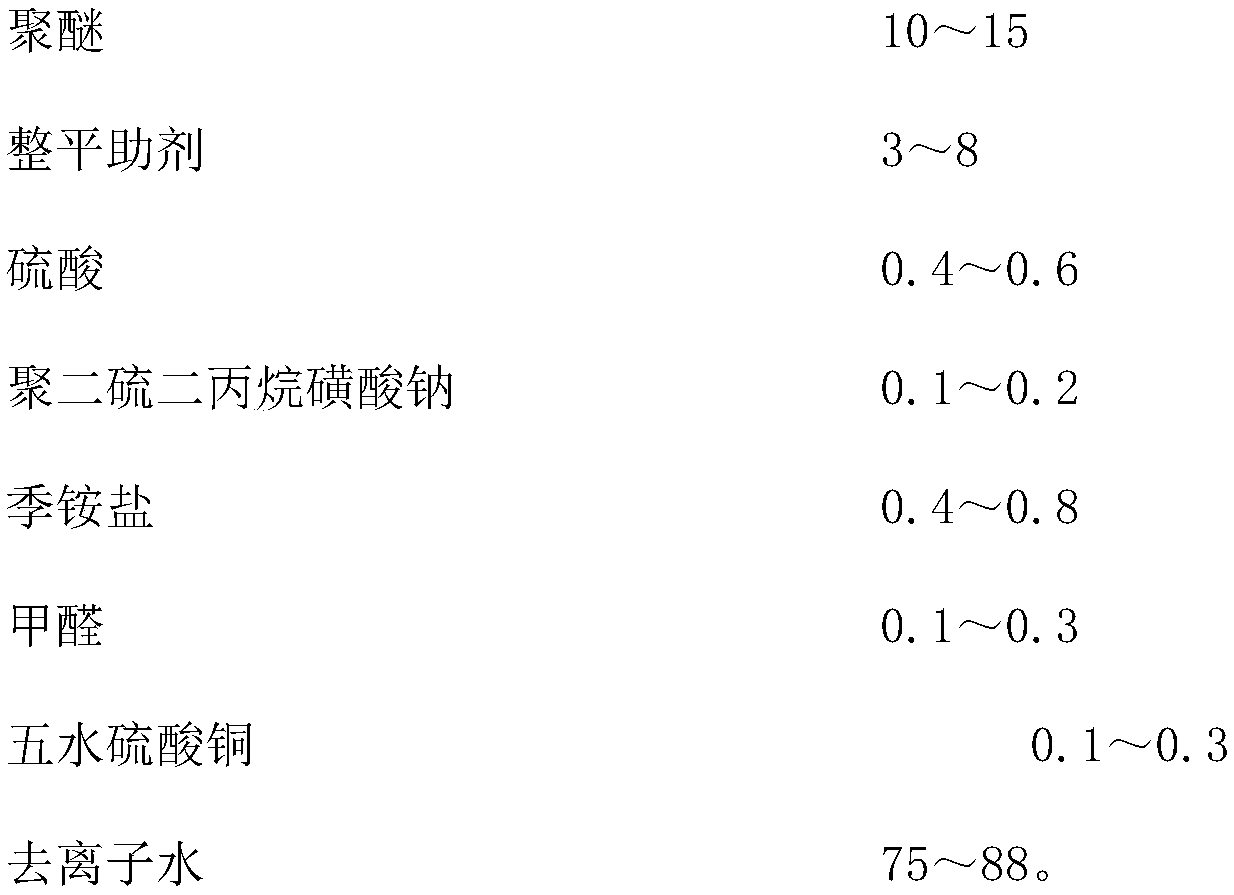

[0020] Components and ratios (parts by weight) are as follows: polyether 10, leveling aid 5, sulfuric acid 0.5, polydithiodipropanesulfonate sodium 0.15, quaternary ammonium salt 0.5, formaldehyde 0.2, copper sulfate pentahydrate 0.25, deionized Water 83.4.

[0021] Preparation steps:

[0022] a. Add deionized water into the reaction kettle, start stirring, slowly add sulfuric acid, and stir evenly.

[0023] b. Add polyether, leveling aid, sodium polydisulfide dipropane sulfonate, and quaternary ammonium salt to the reaction kettle in sequence and stir until completely dissolved.

[0024] c. Add formaldehyde to the reactor and stir evenly.

[0025] d. Add copper sulfate pentahydrate to the reaction kettle, stir until it is completely dissolved and evenly, and then the brightener is prepared

Embodiment 2

[0027] Polyether 12, leveling aid 4, sulfuric acid 0.5, sodium polydisulfide dipropane sulfonate 0.16, quaternary ammonium salt 0.6, formaldehyde 0.24, copper sulfate pentahydrate 0.2, deionized water 82.3. The preparation steps are the same as in Example 1.

Embodiment 3

[0029] Polyether 14, leveling aid 6, sulfuric acid 0.5, sodium polydisulfide dipropane sulfonate 0.15, quaternary ammonium salt 0.7, formaldehyde 0.2, copper sulfate pentahydrate 0.25, deionized water 77.95. Preparation steps are with embodiment 1

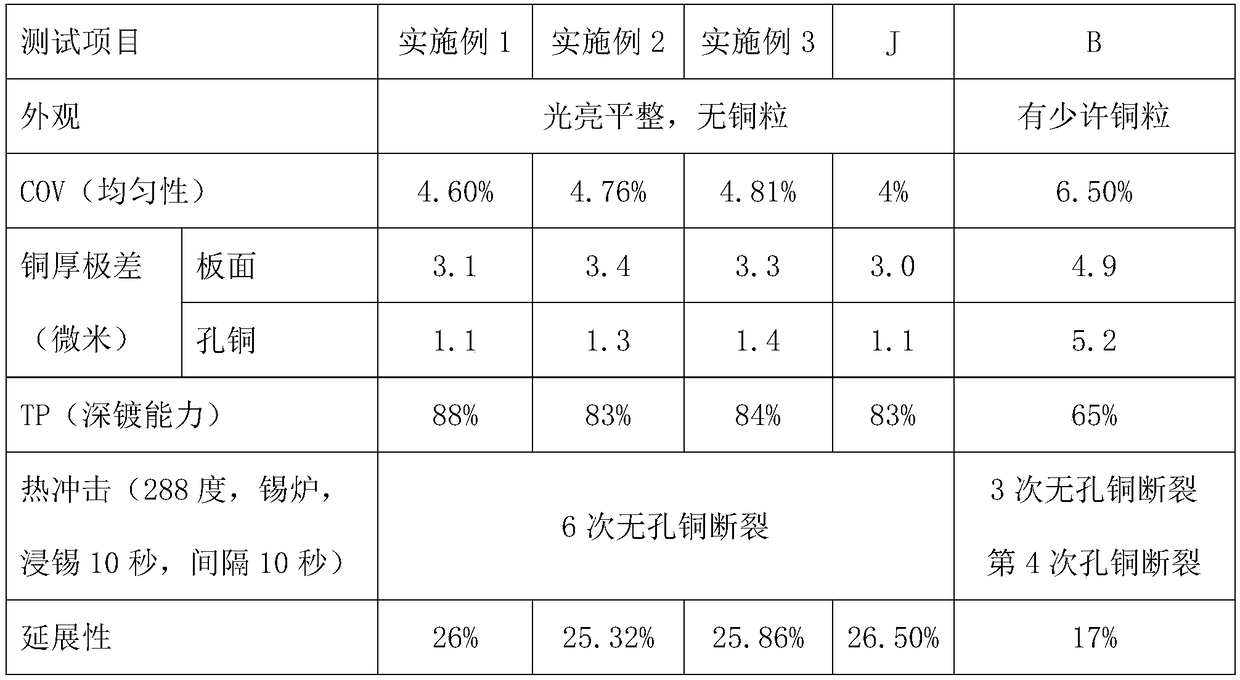

[0030] The VCP high-efficiency copper-plating brightener of the present invention is compared with a brightener of a famous brand in the United States, which is replaced by the code name J, and a brightener of a certain domestic brand is replaced by the code name B, for all-round performance comparison. The specific sample preparation is as follows: PCB with holes drilled There are 25 substrates, 5 boards for each brightener are used as experimental test boards, the test results are averaged, the ratio of thickness to diameter is 8:1, the thickness of substrate copper is 14 microns, the size is 603mm*518mm, the line speed is 0.7m / min, and the copper The thickness is 31.2 microns, and the current density is 4.2ASD.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com