Prefabricated assembly grouting sleeve capable of monitoring grouting fullness and stress variation and manufacturing method thereof

A grouting sleeve, prefabricated assembly technology, applied in the direction of force measurement, measurement force, measurement device, etc. by measuring the change of optical properties of the material when it is under stress, can solve problems such as anxiety, and ensure the monitoring effect and signal transmission distance. Long, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

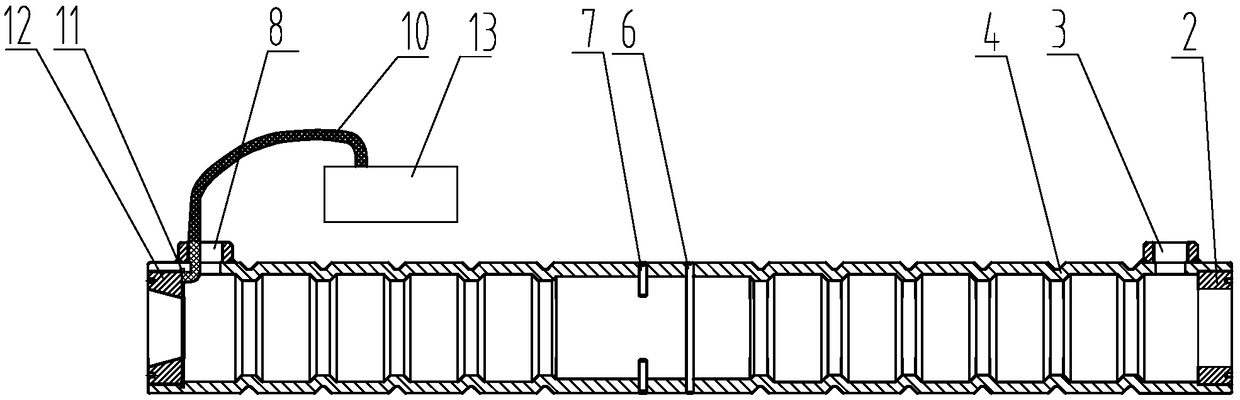

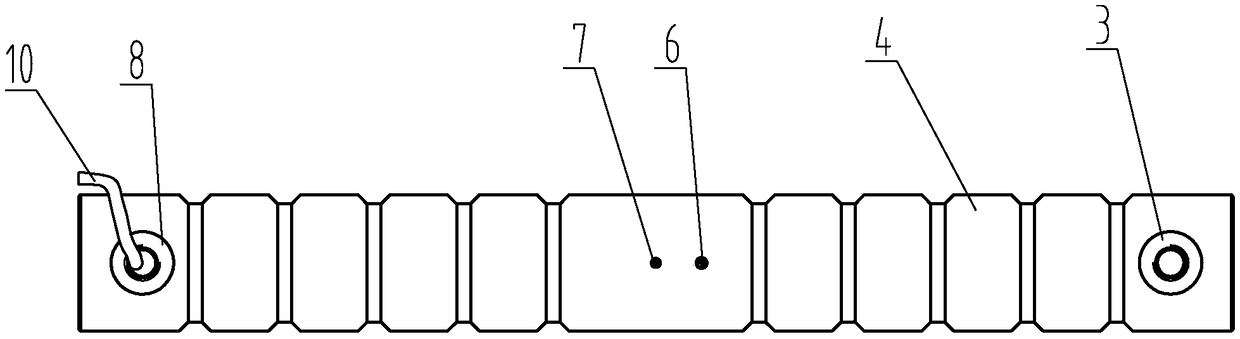

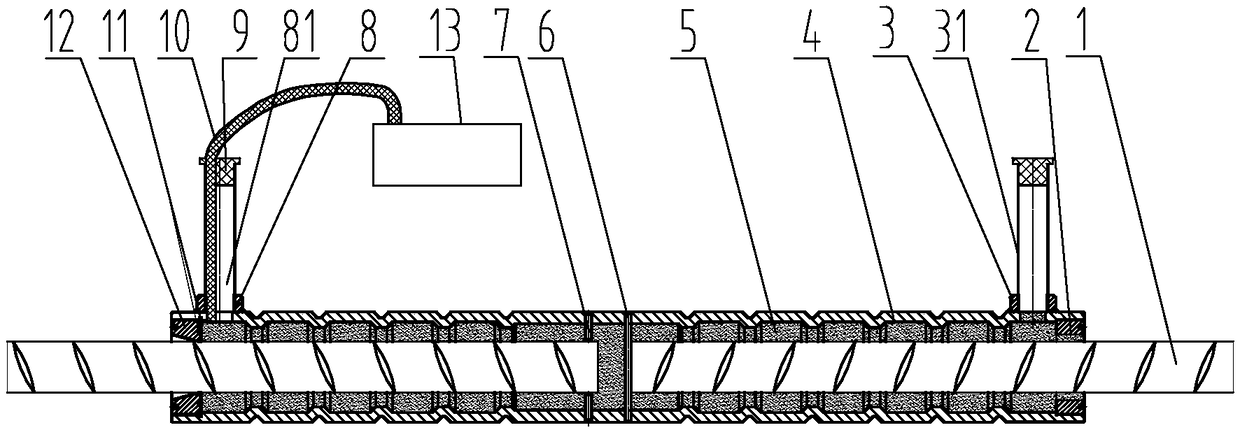

[0041] A prefabricated assembled grouting sleeve capable of monitoring grouting fullness and stress changes, including a grouting sleeve body 4 with a cavity, the grouting sleeve body 4 is rolled from ordinary round steel, the grouting sleeve Both ends of the body 4 are the insertion ends of the steel bar 1, and one port of the grouting sleeve body 4 is provided with a sealing ring 2, and the other port is provided with a sealing end cap 12, and the sealing end cap 12 is connected with the grouting sleeve body. 4 is threaded; the grouting sleeve body 4 is provided with a grouting port 3 on the side of one end of the sealing ring 2, and the grouting sleeve body 4 is provided with a grouting port 8 on the side of one end of the sealing end cover 12; The middle part of the grouting sleeve body 4 is also provided with a positioning pin 6 and a centering pin 7 respectively; the prefabricated assembled grouting sleeve also includes a fiber grating sensor 11 and a demodulator 13; the ...

Embodiment 2

[0053] A method for manufacturing a prefabricated assembled grouting sleeve capable of monitoring grouting fullness and stress changes, which is a method of installing and manufacturing a prefabricated assembled grouting sleeve described in Embodiment 1 that can monitor grouting fullness and stress changes; Include the following steps:

[0054] A. Material preparation: Prepare the round steel used to make the grouting sleeve body;

[0055] B. Install the corresponding rolling tooling used to make the grouting sleeve body;

[0056] C. Roll forming grouting sleeve body 4;

[0057] D. According to the technical requirements, the grouting sleeve body 4, the sealing ring 2 and the sealing end cover 12 are all processed with grooves and holes;

[0058] E. Weld grouting port 3 and grouting port 8;

[0059] F. After cleaning the fiber grating sensor 11, stick it in the small installation groove and weld the lead wire on one side;

[0060] G. Welding the lead wire of the fiber grat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com