Anti-surge control method of high-pressure waste gas recycling supercharger of diesel engine

A technology of exhaust gas recirculation and control method, which is applied in the direction of electrical control, engine control, fuel injection control, etc., which can solve problems such as increased fuel consumption, slowing down of changes in intake air volume and intake pressure, and affecting acceleration performance. Intake resistance, noise and movement avoidance, surge avoidance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

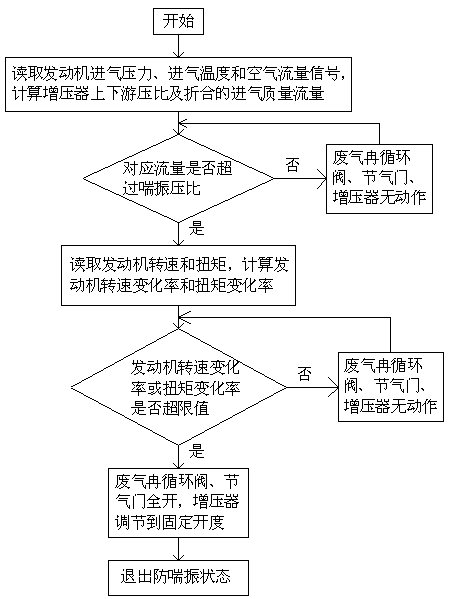

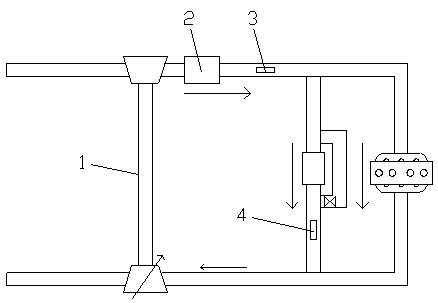

[0073] Please see attached image 3 , with image 3 It is a typical layout of the intake and exhaust system of diesel engines above the National V. Considering reducing NOx emission and increasing EGR rate, and pursuing higher engine torque output, usually a higher target pressure is set for the supercharger, which increases the risk of supercharger surge, especially at some sudden torque and speed. drop under transient conditions.

[0074] Use the signal of the intake pressure sensor to get the inlet pressure P 21 =1880hPa and air mass flow rate dmAir=170kg / h, the outlet pressure P of the supercharger compressor is calculated according to the pipeline pressure model 20 =1904hPa; similarly use the ambient pressure P 0 =1009hPa and air mass flow rate dmAir=170kg / h, the inlet pressure P of the turbocharger is calculated according to the pipeline pressure model 1 =1001hPa, finally get the actual pressure ratio of the supercharger CR=P 20 / P 1 =1.887. And each supercharger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com