A heating pipe network system and self-adaptive control method

A technology of heating pipe network and main control system, which is applied in the direction of heating system, heating method, household heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing this description is further described:

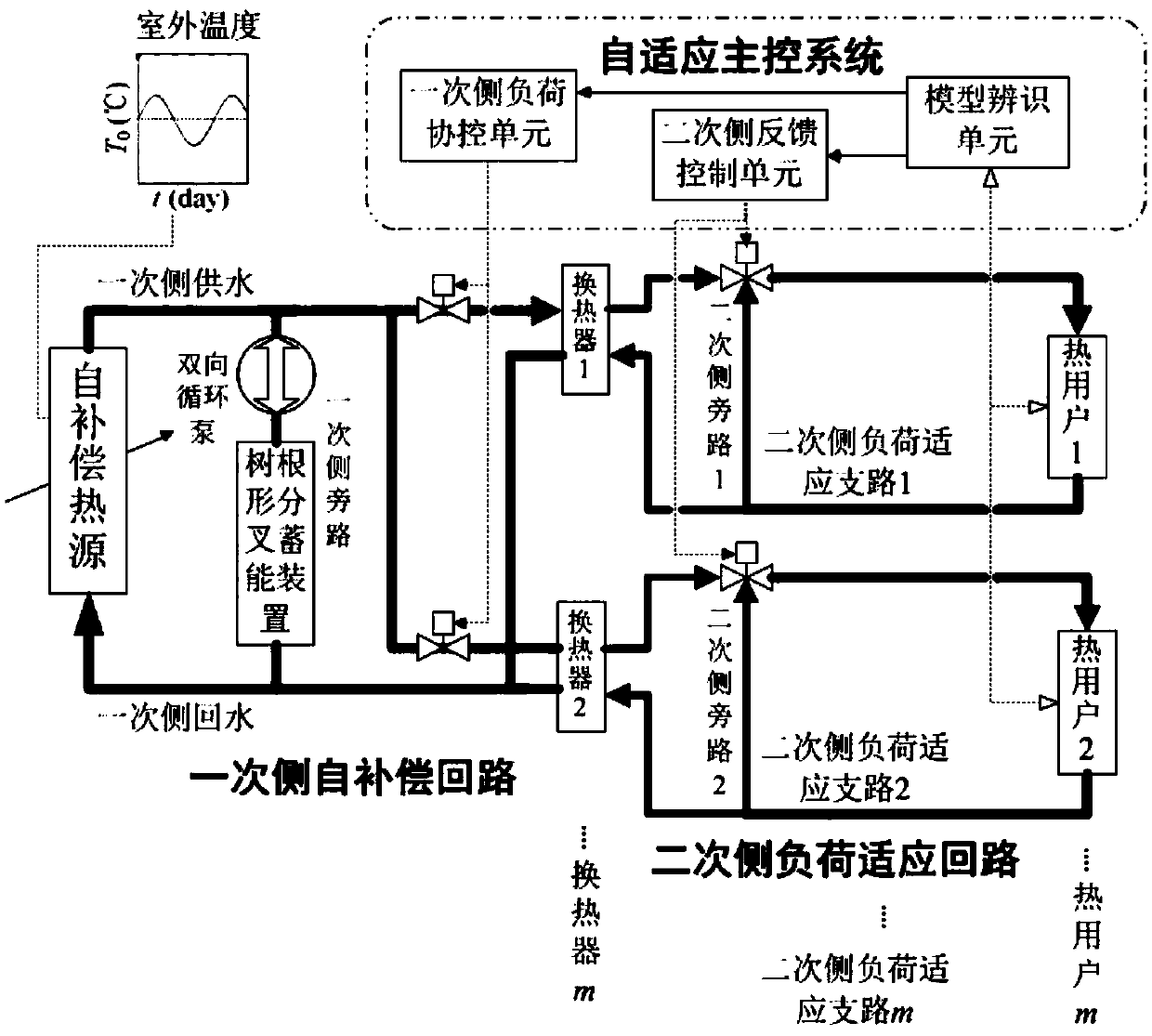

[0048] The present invention proposes a heating pipe network system and an adaptive control method. The structure of the heating pipe network and its adaptive system is as follows: figure 1 As shown, the heating pipe network system consists of three parts: the primary side self-compensation loop, the secondary side load adaptation loop, and the self-adaptive main control system. figure 1 Among them, the primary side self-compensation circuit includes self-compensation heat source, tree root-shaped hierarchical energy storage device, bidirectional circulation pump, primary side temperature control unit and heat exchanger. The secondary side load adaptation circuit includes m secondary side load adaptation branches with different heating characteristics, and the m secondary side load adaptation branches obtain the required energy from the primary side self-compensation circuit through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com