A food safety risk online assessment and control method

A technology for food safety and control methods, applied in data processing applications, instruments, calculations, etc., can solve problems such as large hidden dangers of food safety, untimely detection, long sampling and testing cycles, etc., to reduce product hazards and prevent products from entering the market. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

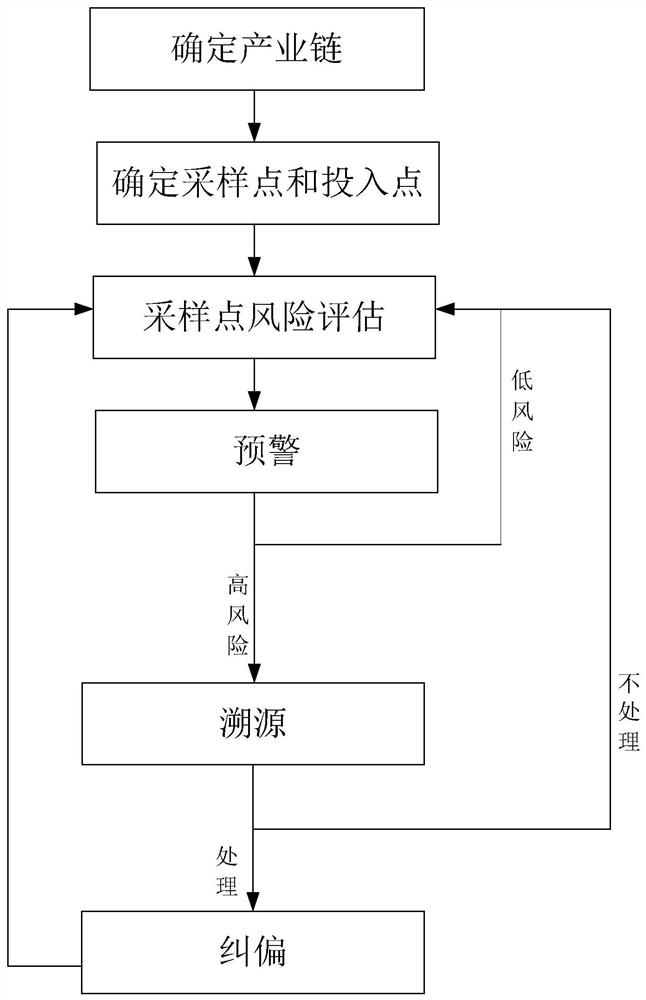

[0039] A food safety risk online assessment and control method, such as figure 1As shown, the following steps are included: (1) Determine the industrial chain; (2) Determine the material input point i with material input on the industrial chain, and correspond to the sampling point at the input point i, and set other sampling points in addition according to HACCP requirements; (3) Risk assessment: Calculate the sampling density, the content of hazard factors at the input point, the risk index, and the degree of risk to evaluate the risk of the final product; (4) Early warning: conduct early warning analysis based on the evaluation results of step (3), and enter the step for high risk (5), low-risk, enter the next sampling point and repeat step (3); (5) traceability: step (4) early warning enters the traceability program, finds the hazard node on the industrial chain, and enters step (6) when the node is the input point of the input , the hazard node is not the input point of t...

Embodiment 2

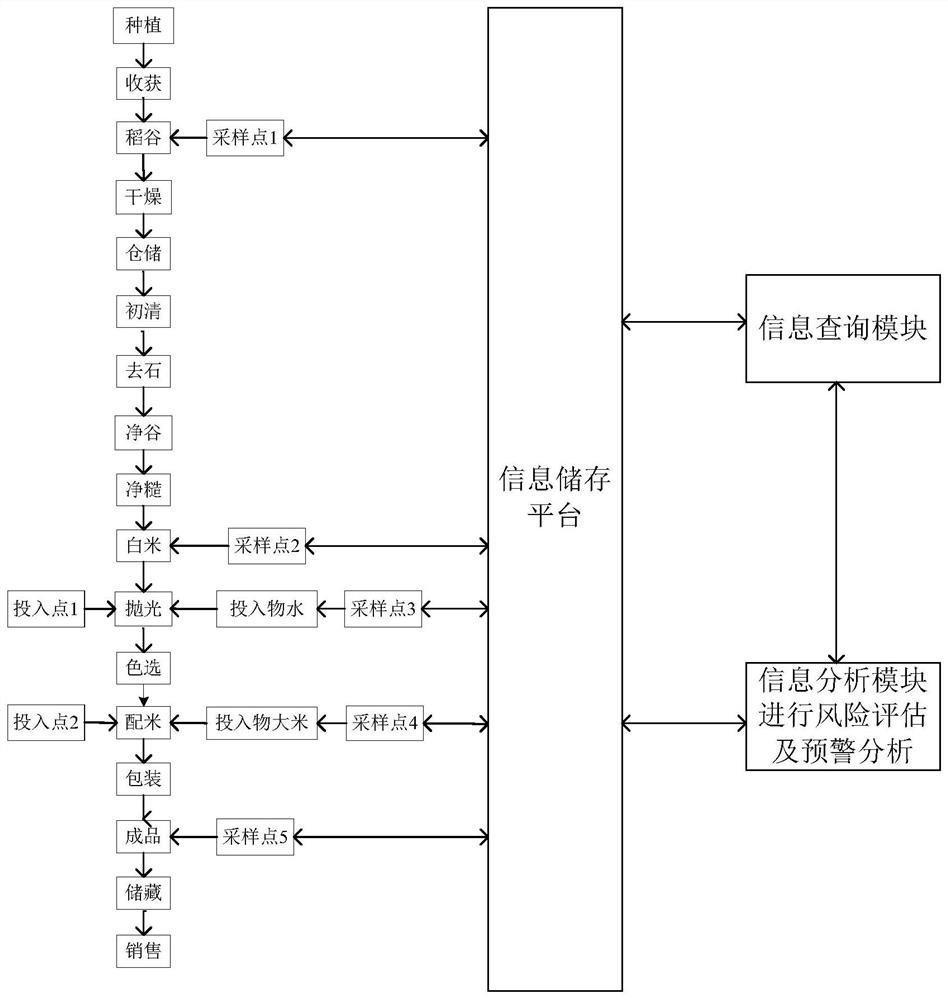

[0041] Taking the rice production and processing industry chain as an example, the specific operation steps of the online rice safety risk assessment and control method are as follows:

[0042] (1) Determine the rice industry chain: establish an industry chain including rice production and processing according to the rice processing process, such as figure 2 shown;

[0043] (2) Determine sampling points and material input points: according to the industrial chain determined in step (1), set sampling point j on the industrial chain, set the first sampling point 1 at the paddy, and set the first sampling point 1 at the paddy after processing into rice and before polishing. Two sampling points 2, the polishing agent water in the polishing process is the third sampling point 3, the rice added in the rice blending process is the fourth sampling point 4, the fifth sampling point 5 is set at the finished product, and the same sampling point is calculated The time C between the two ...

Embodiment 3

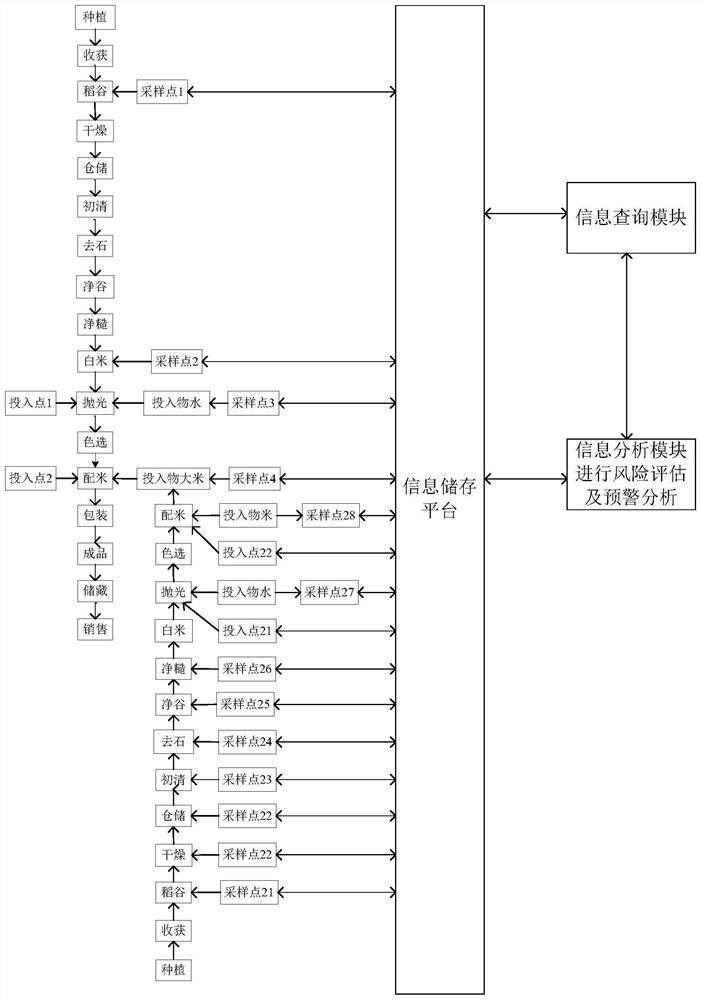

[0068] A food safety risk online assessment and control method, the process flow is as follows figure 1 shown. The online assessment and control method of food safety risk is applied to the online assessment and control of heavy metal content in rice, and the specific steps are as follows:

[0069] (1) Determine the industrial chain: determine the industrial chain of food from source to dining table, including food production and processing technology; and industrial branch chains including all inputs, such as image 3 shown;

[0070] (2) Determine the sampling points and material input points: list the material input points during the processing process. In the main industrial chain, the material input points are polishing and rice blending. In the industrial branch chain, the material input points are also polishing With rice distribution; the setting of the sampling point of the main industry chain is the same as that of embodiment 2, and each processing node in the branc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com