Solar cell preparation method and solar cell module

A solar cell and module technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problem of low output power of solar cell modules, and achieve the effect of reducing current, reducing electrical loss, and preventing fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

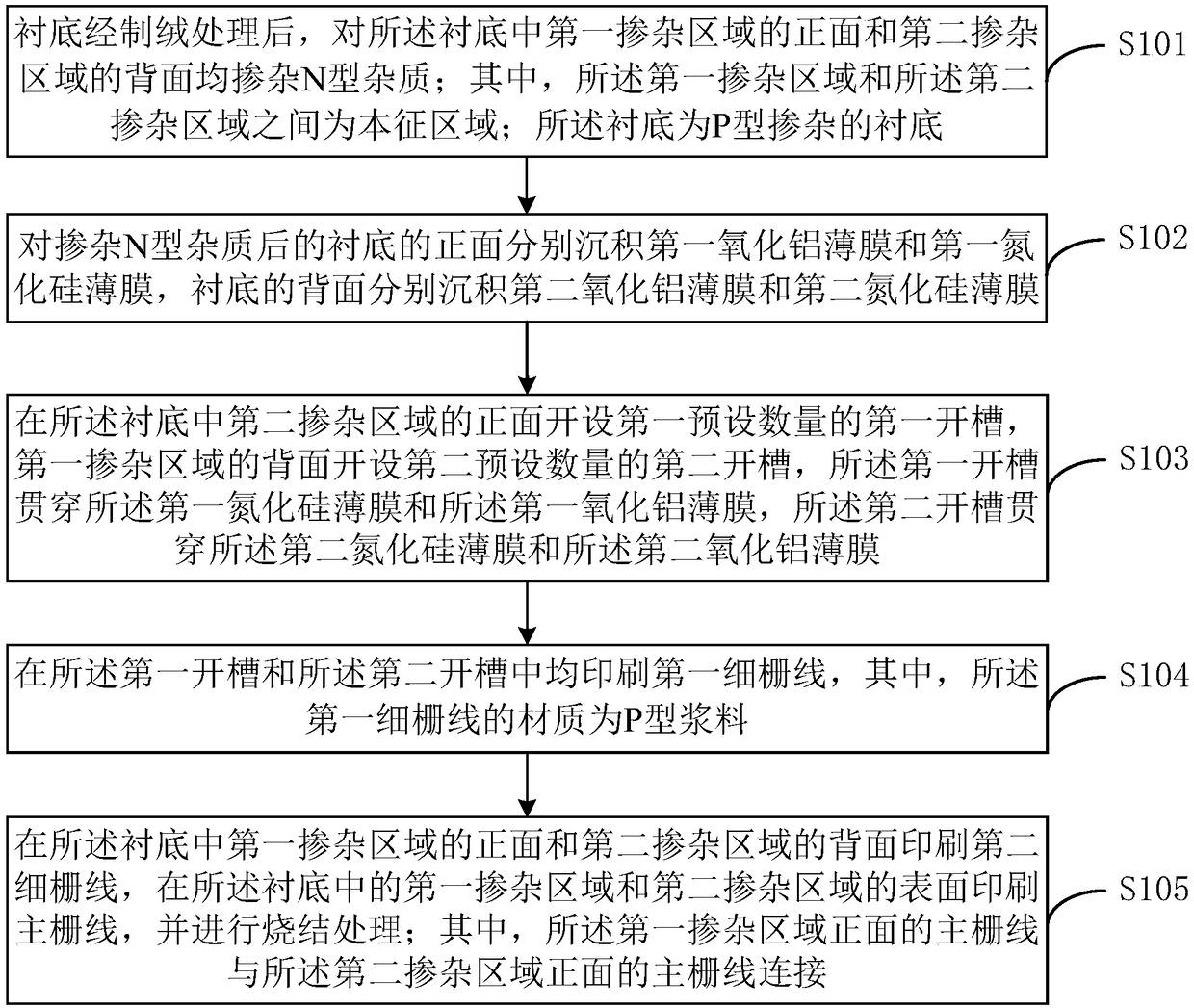

[0035] Please refer to figure 1 , the preparation method of solar cell comprises:

[0036] Step S101, after the substrate is textured, both the front side of the first doped region and the back side of the second doped region in the substrate are doped with N-type impurities; wherein, the first doped region and the Intrinsic regions are between the second doped regions; the substrate is a P-type doped substrate.

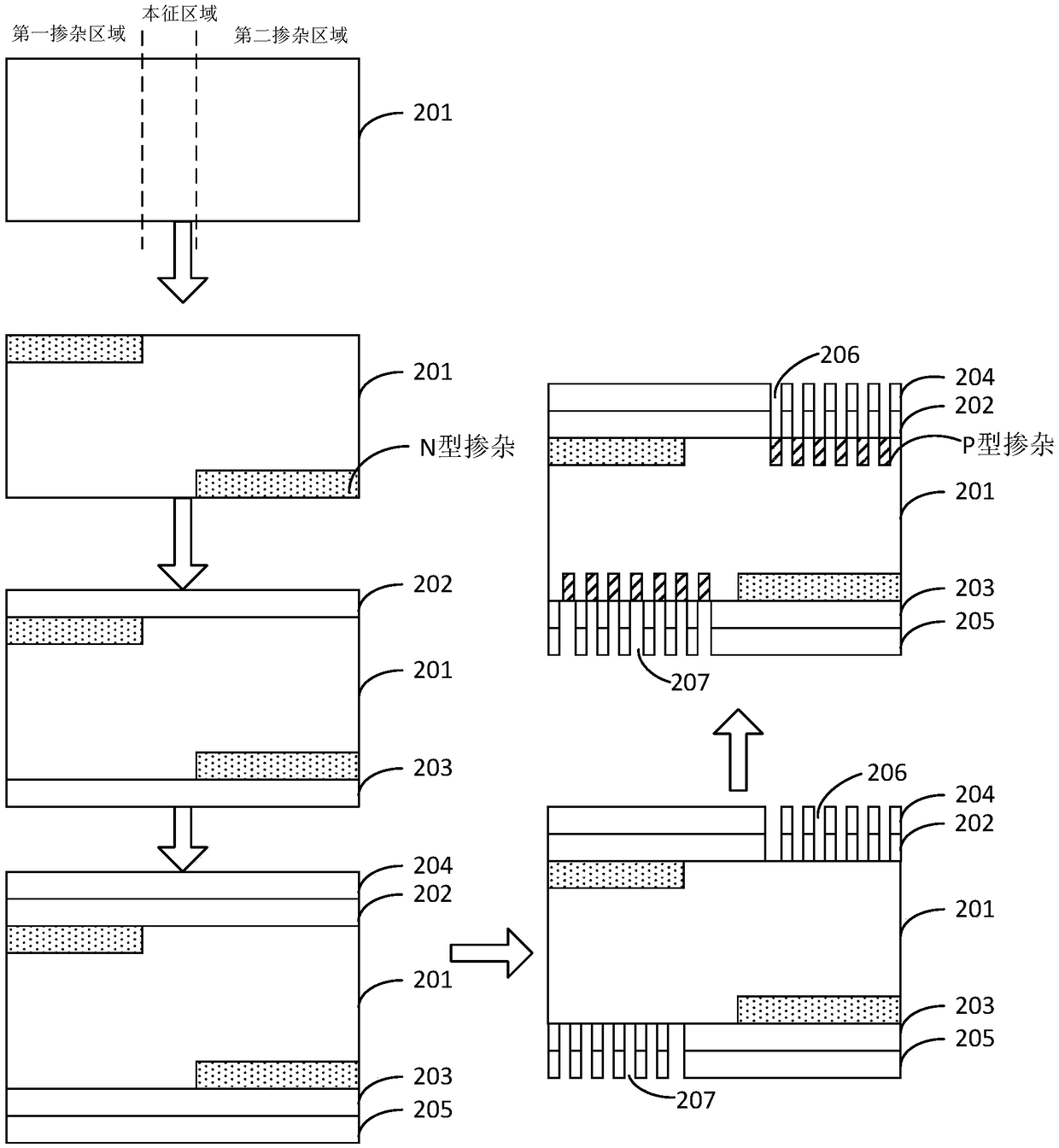

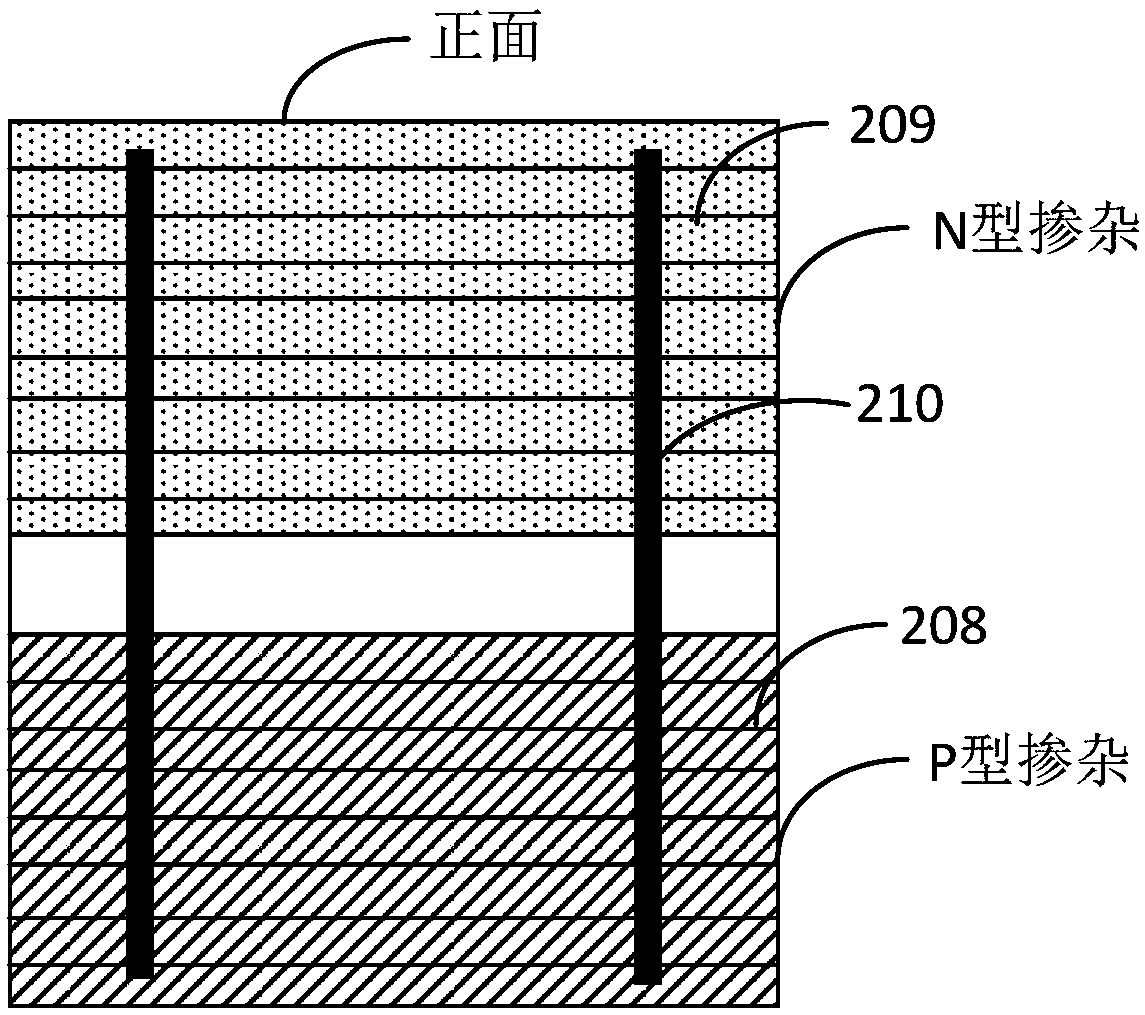

[0037] In the embodiment of the present invention, the substrate 201 is a P-type silicon substrate, and a passivated emitter and a rear local contact (Passivated Emitter Rear Contact, PERC) cell are prepared on the P-type silicon substrate. Such as figure 2 As shown, the substrate 201 is divided into a first doped region, an intrinsic region and a second doped region. The shapes of the first doped region, the second doped region and the intrinsic region include but are not limited to rectangles, trapezoids, triangles and other polygons. Preferably, the first dop...

Embodiment 2

[0065] A solar cell, which is prepared by the method for preparing a solar cell as described in Embodiment 1 of the present invention, and has the beneficial effects of Embodiment 1 of the present invention.

Embodiment 3

[0067] Please refer to Figure 5 and Figure 6 , a solar cell assembly obtained by connecting a plurality of solar cells as described in Embodiment 2 of the present invention through a ribbon 300, and has the beneficial effects of Embodiment 2 of the present invention.

[0068] Optionally, the soldering ribbon 300 is disposed on the backlight surface of the plurality of solar cells.

[0069] In the embodiment of the present invention, no welding ribbon is provided on the light-receiving surface of the solar cell, and the welding ribbon is arranged on the backlight surface of the solar cell, and two adjacent solar cells are connected in series through the welding ribbon 300, thereby reducing the usage of the welding ribbon 300 and reducing the Power loss due to ribbon shadowing.

[0070] Optionally, the width of the welding ribbon 300 is 1 mm to 3 mm.

[0071] In the embodiment of the present invention, the width of the welding ribbon 300 is controlled. When the width of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com