A lithium ion battery positive electrode bind and application thereof

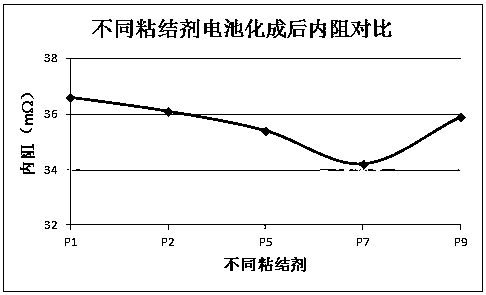

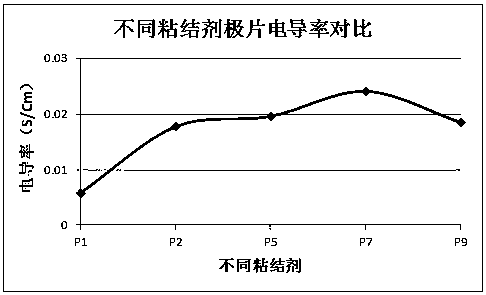

A lithium-ion battery and binder technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low adhesion, insoluble, and reduced flexibility, and achieve improved electronic conductivity and ionic conductivity. The effect of high rate and low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Dissolve the binder P1 (polyvinylidene fluoride with a molecular weight of 3000~50,000) in NMP and stir to form a transparent, bubble-free glue, then add conductive carbon black and positive electrode active materials to the glue in turn, after high-speed Stir, disperse, and suction filter to form a positive electrode slurry with uniformity, moderate viscosity, no graininess and good fluidity.

[0013] After coating, baking, sheeting, rolling, slitting, winding, shelling, spot welding, baking, liquid injection, and sealing, the 18650 lithium-ion battery is formed.

[0014] Carry out formation and cycle tests at a rate of 0.1~1C, and test the internal resistance voltage of the battery after formation.

Embodiment 2

[0016] The binder P2 (polyvinylidene fluoride with a molecular weight of 100,000 to 300,000) was dissolved in NMP and stirred to form a transparent, bubble-free glue solution, and then conductive carbon black and positive electrode active materials were added to the glue solution in sequence. High-speed stirring, dispersing, and suction filtration form a positive electrode slurry with uniformity, moderate viscosity, no graininess and good fluidity.

[0017] After coating, baking, sheeting, rolling, slitting, winding, shelling, spot welding, baking, liquid injection, and sealing, the 18650 lithium-ion battery is formed.

[0018] Carry out formation and cycle tests at a rate of 0.1~1C, and test the internal resistance voltage of the battery after formation.

Embodiment 3

[0020] The binder P5 (polyvinylidene fluoride with a molecular weight of 300,000 to 500,000) was dissolved in NMP and stirred to form a transparent, bubble-free glue, and then conductive carbon black and positive active materials were added to the glue in turn. High-speed stirring, dispersing, and suction filtration form a positive electrode slurry with uniformity, moderate viscosity, no graininess and good fluidity.

[0021] After coating, baking, sheeting, rolling, slitting, winding, shelling, spot welding, baking, liquid injection, and sealing, the 18650 lithium-ion battery is formed.

[0022] Carry out formation and cycle tests at a rate of 0.1~1C, and test the internal resistance voltage of the battery after formation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com