Automatic stagewise coating system for large vessels

An automatic painting and ship technology, which is applied to ship parts, spraying devices, ship construction, etc., can solve the problems of narrow spraying width, potential safety hazards, and low speed, so as to ensure efficiency and quality, reduce manual participation, and reduce Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

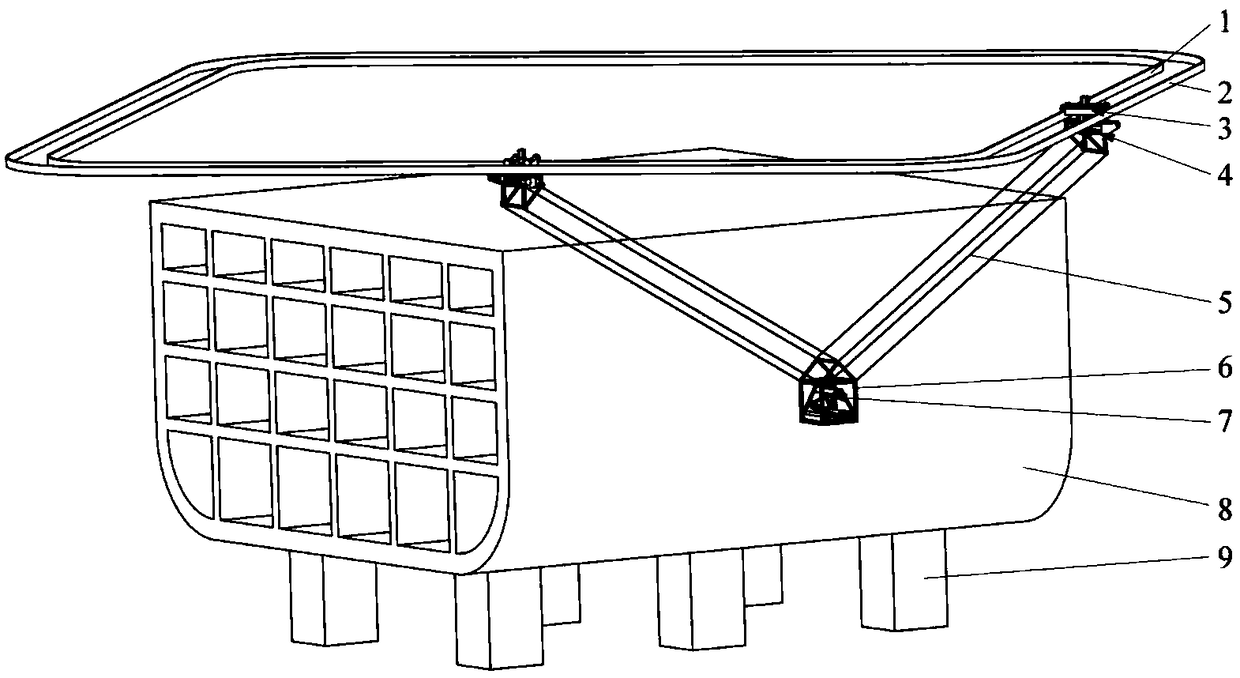

[0028] Such as figure 1 Shown is a schematic diagram of a segmented automatic coating system for large ships. The segmented automatic coating system for large ships consists of a sliding track, a cable-driven automated coating robot system, a segmented hull 8 and a support column 9 for a large ship. The sliding track is divided into an inner track 1 and an outer track 2, and the inner and outer tracks form a ring. The inner track 1 and the outer track 2 are installed on the top of the factory building, which is more than 2 meters above the top of the segmented hull 8 of the large ship. The segmented hull 8 of a large ship is supported by a support column 9, and is placed in the factory building and is located in the ring-shaped area formed by the inner and outer rails.

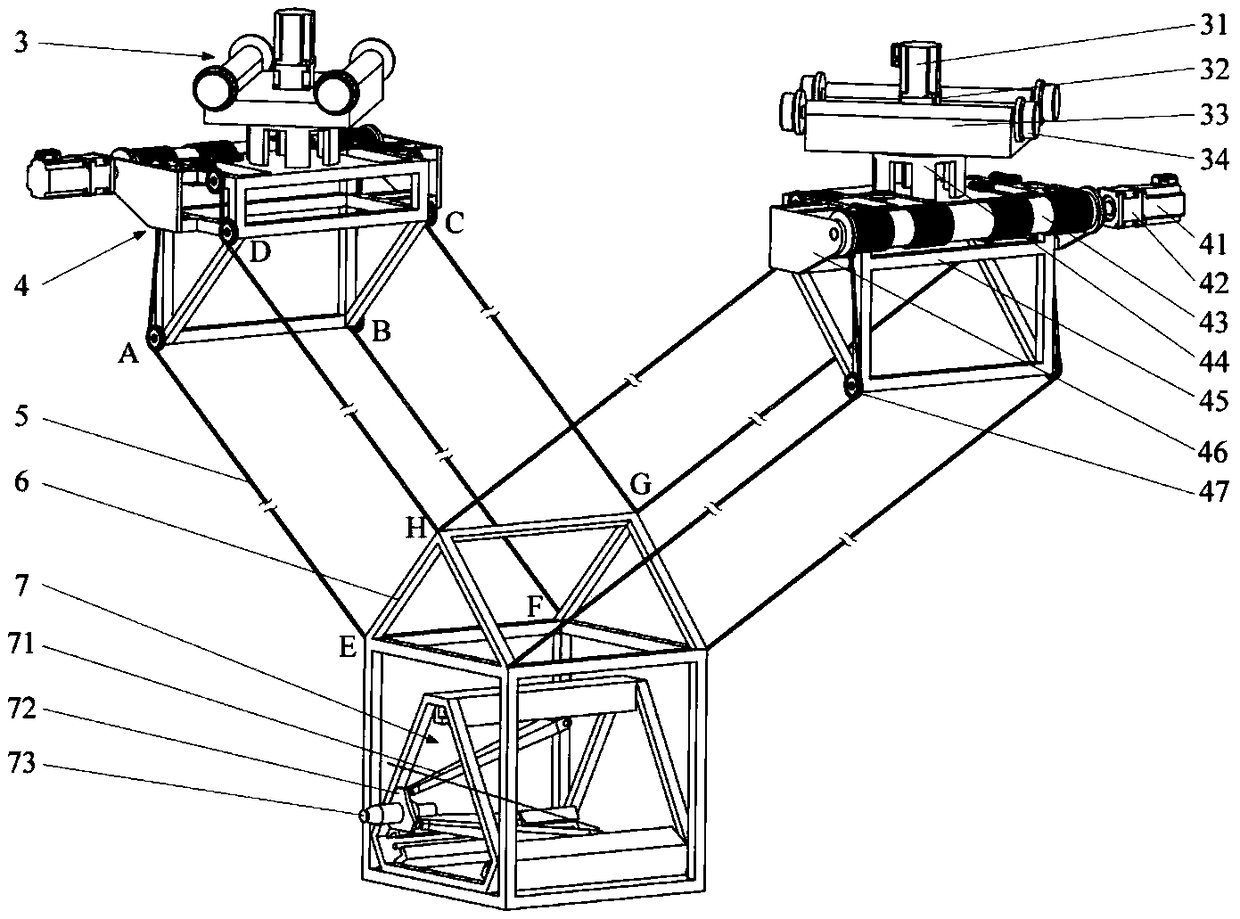

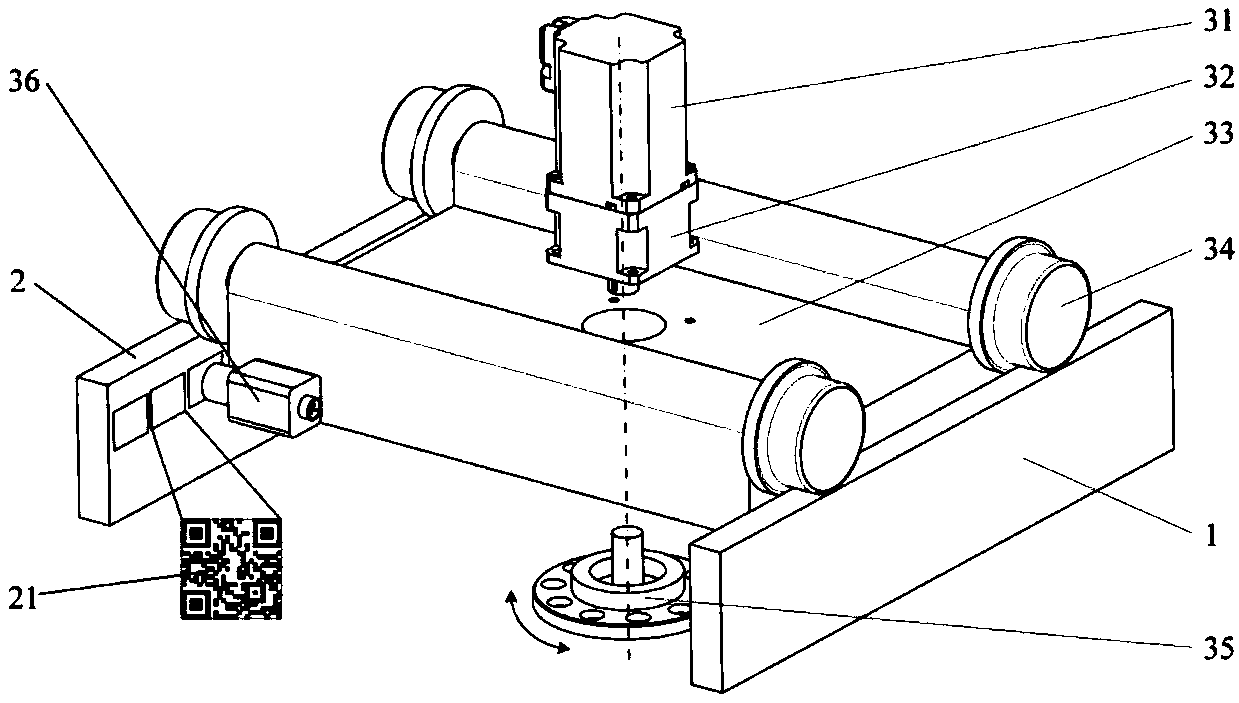

[0029] The cable-driven automatic painting robot system includes a first-level cable-dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com