Waste tire recycling system for large-scale customization

A technology for recycling and processing waste tires, which is applied in the field of resource recycling of waste tires and recycling and processing systems of waste tires, can solve the problems of only 60% harmless utilization rate and lack of equipment, so as to prevent secondary pollution and improve The effect of production efficiency and rapid configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the drawings and specific embodiments.

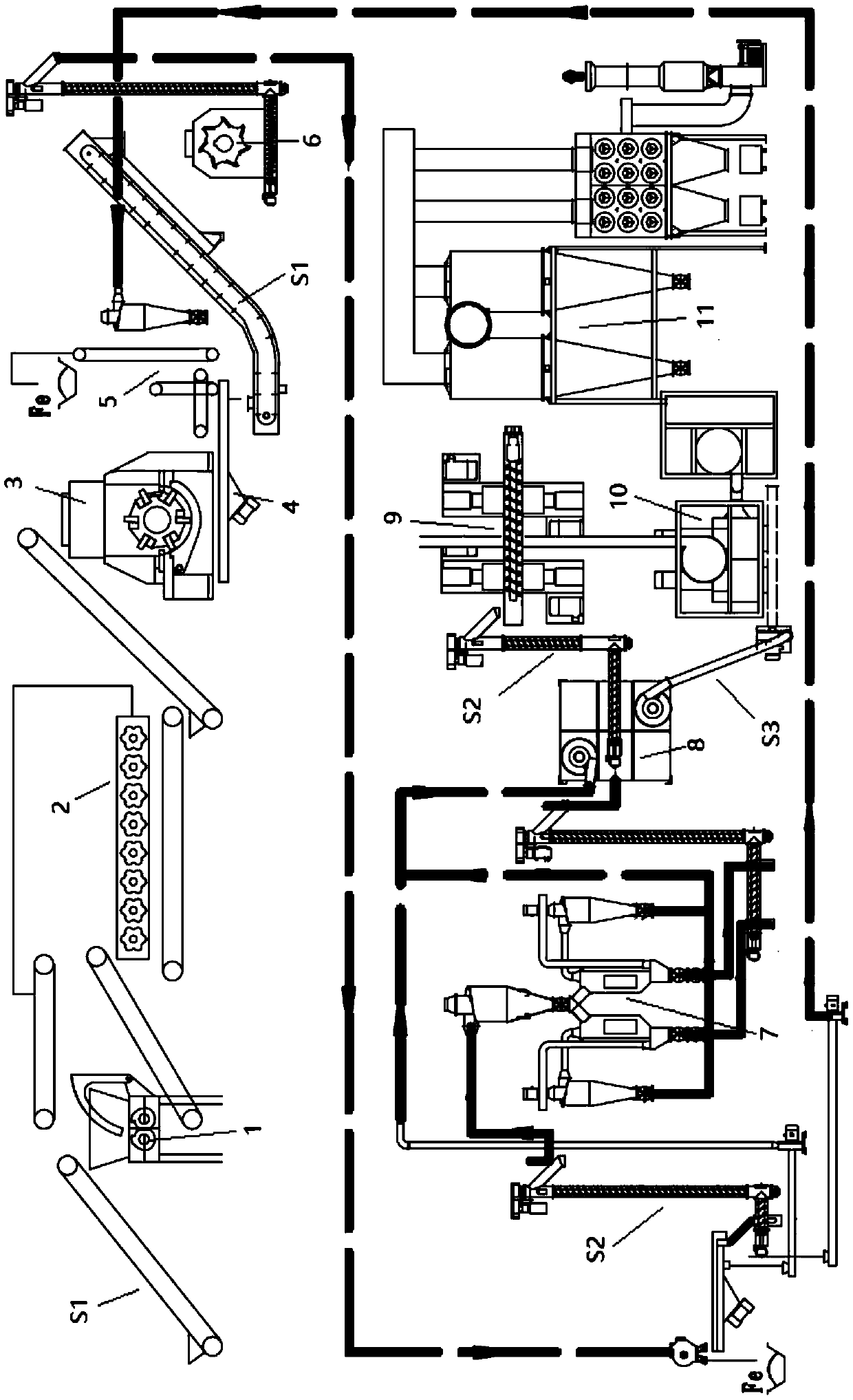

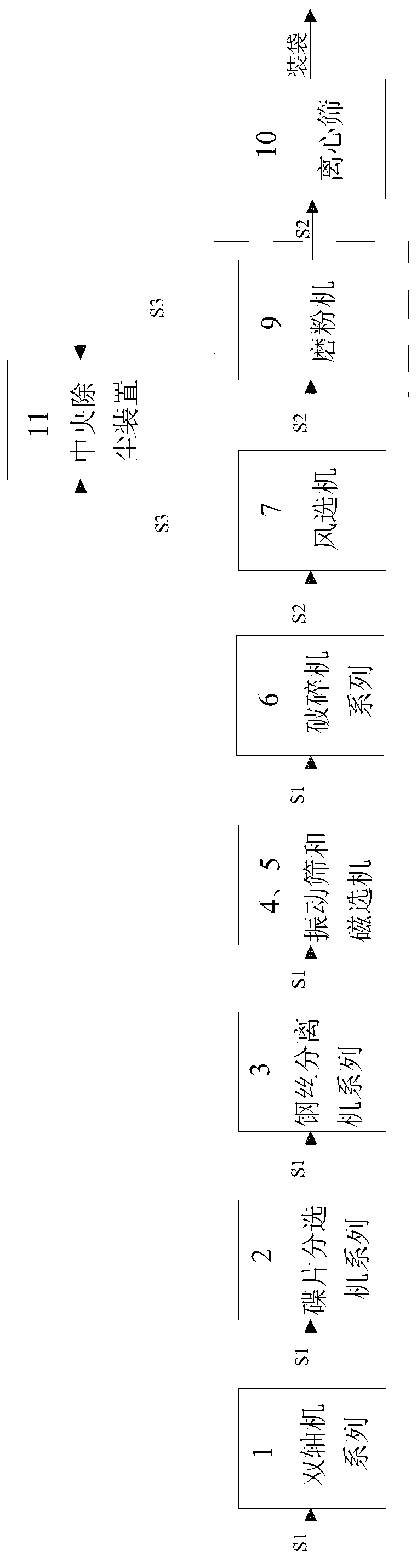

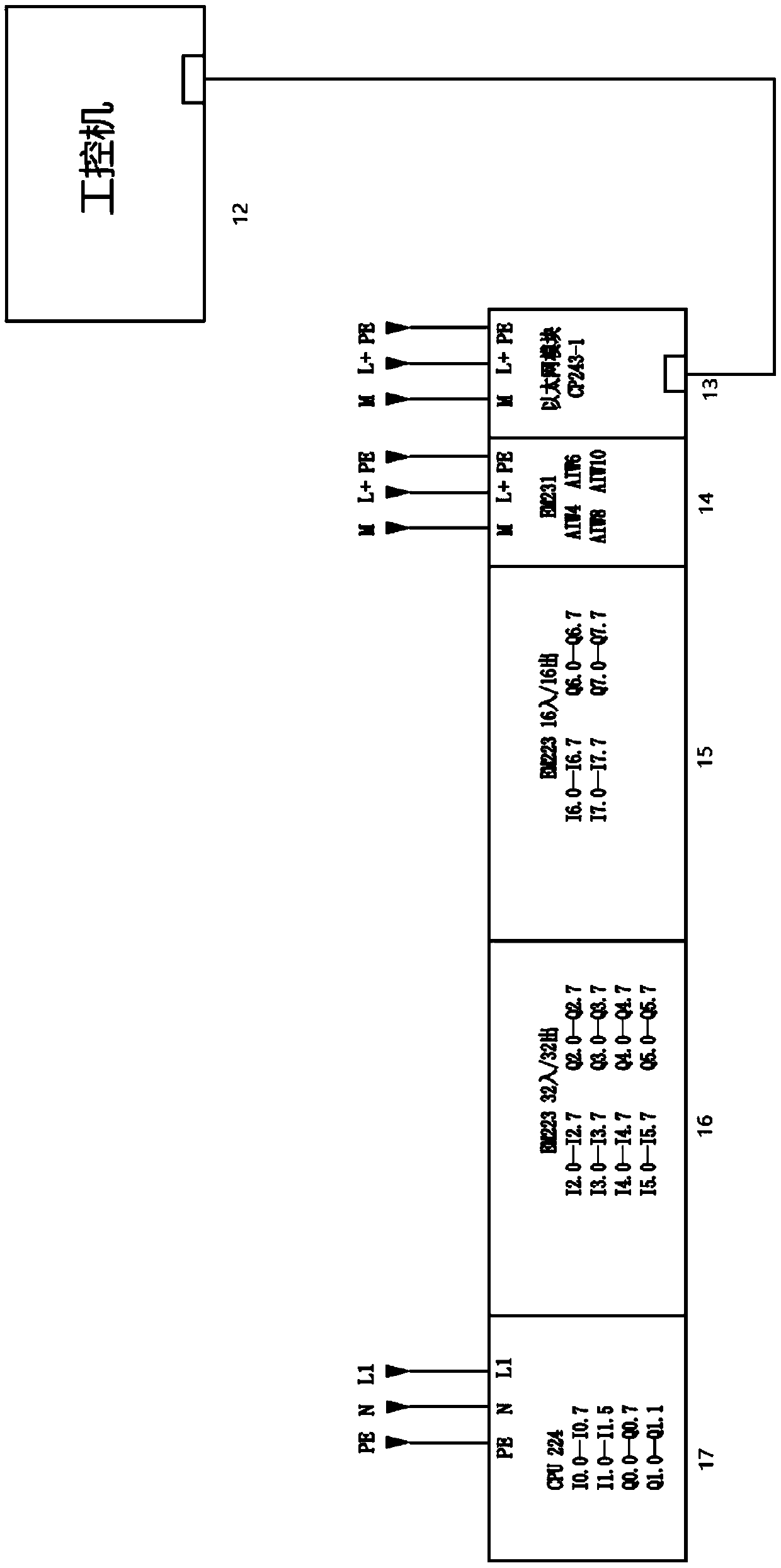

[0031] A recycling and processing system of waste tires for large-scale customization, such as figure 1 with figure 2 As shown, the waste tire recycling and processing system is customized according to the needs of different customers, and the corresponding waste tire recycling and processing production line is configured. The production line is composed of a mechanical part and an electrical control part; among them, the mechanical part is a two-axis machine 1, Disc sorting machine 2, steel wire separator 3, vibrating screen 4 and drum magnetic separator 5, crusher 6, air separator 7, storage hopper 8, mill 9, centrifugal screen 10, central dust removal device 11, And the conveyor belt S1, the screw conveyor S2, and the sealed pipe S3 connecting them; the electrical control part is composed of the industrial computer 12, the programmable controller 17, the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com