Culture method for obtaining high-content glycerol glucoside algae cells

A breeding method, glucose technology, applied to bacteria, adding compounds to stimulate growth, fermentation, etc., can solve the problems that cannot meet the requirements of industrial application, and achieve the effect of reducing the cost of separation and extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

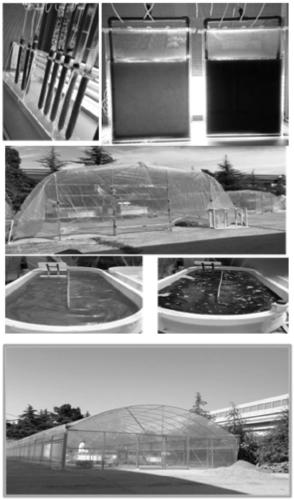

[0095] A culture method for obtaining spirulina cells with high content of glycerol glucoside, the reactor used in the method is a 10L plate reactor. The specific implementation of the method includes the following steps:

[0096] (1) Obtain the cultured algae cell stage:

[0097] This algae cell is inoculated in the low-salt freshwater medium Zarrouk substratum (see Table 1 and Table 2 for details), and initial inoculation concentration is 0.2g / L, and the temperature program of the freshwater medium of controlling cultivation this algae cell is: constant temperature 25°C, the light program is: continuous light, the light intensity is 500μE·m -2 ·s -2, the light wavelength range is 400-700nm, the ventilation volume is: 0.3VVM, the gas passed through is mixed air containing carbon dioxide, and the carbon dioxide concentration is 5% (v / v).

[0098] The culture time at this stage is 5-7 days.

[0099] (2) GG elevation stage:

[0100] The algae cells are selected from the cel...

Embodiment 2

[0105] A culture method for obtaining spirulina cells with high content of glycerol glucoside, the reactor used in the method is a 10L plate reactor. The specific implementation of the method includes the following steps:

[0106] (1) Obtain the cultured algae cell stage:

[0107] This algae cell is inoculated in the low-salt freshwater medium Zarrouk culture medium (see table 1 and table 2 for details), and initial inoculation concentration is 0.2g / L, and the temperature program of the freshwater medium of controlling cultivation this algae cell is: constant temperature 25°C, the light program is: continuous light, the light intensity is 500μE·m -2 ·s -2 , the light wavelength range is 400-700nm, the ventilation volume is: 0.3VVM, the gas passed through is mixed air containing carbon dioxide, and the carbon dioxide concentration is 5% (v / v).

[0108] The culture time at this stage is 5-7 days.

[0109] (2) GG elevation stage:

[0110] The algae cells are selected from th...

Embodiment 3

[0115] A culture method for obtaining spirulina cells with high content of glycerol glucoside, the reactor used in the method is a 10L plate reactor. The specific implementation of the method includes the following steps:

[0116] (1) Obtain the cultured algae cell stage:

[0117] This algae cell is inoculated in the low-salt freshwater medium Zarrouk culture medium (see table 1 and table 2 for details), and initial inoculation concentration is 0.2g / L, and the temperature program of the freshwater medium of controlling cultivation this algae cell is: constant temperature 25°C, the light program is: continuous light, the light intensity is 500μE·m -2 ·s -2 , the light wavelength range is 400-700nm, the ventilation volume is: 0.3VVM, the gas passed through is mixed air containing carbon dioxide, and the carbon dioxide concentration is 5% (v / v).

[0118] The culture time at this stage is 5-7 days.

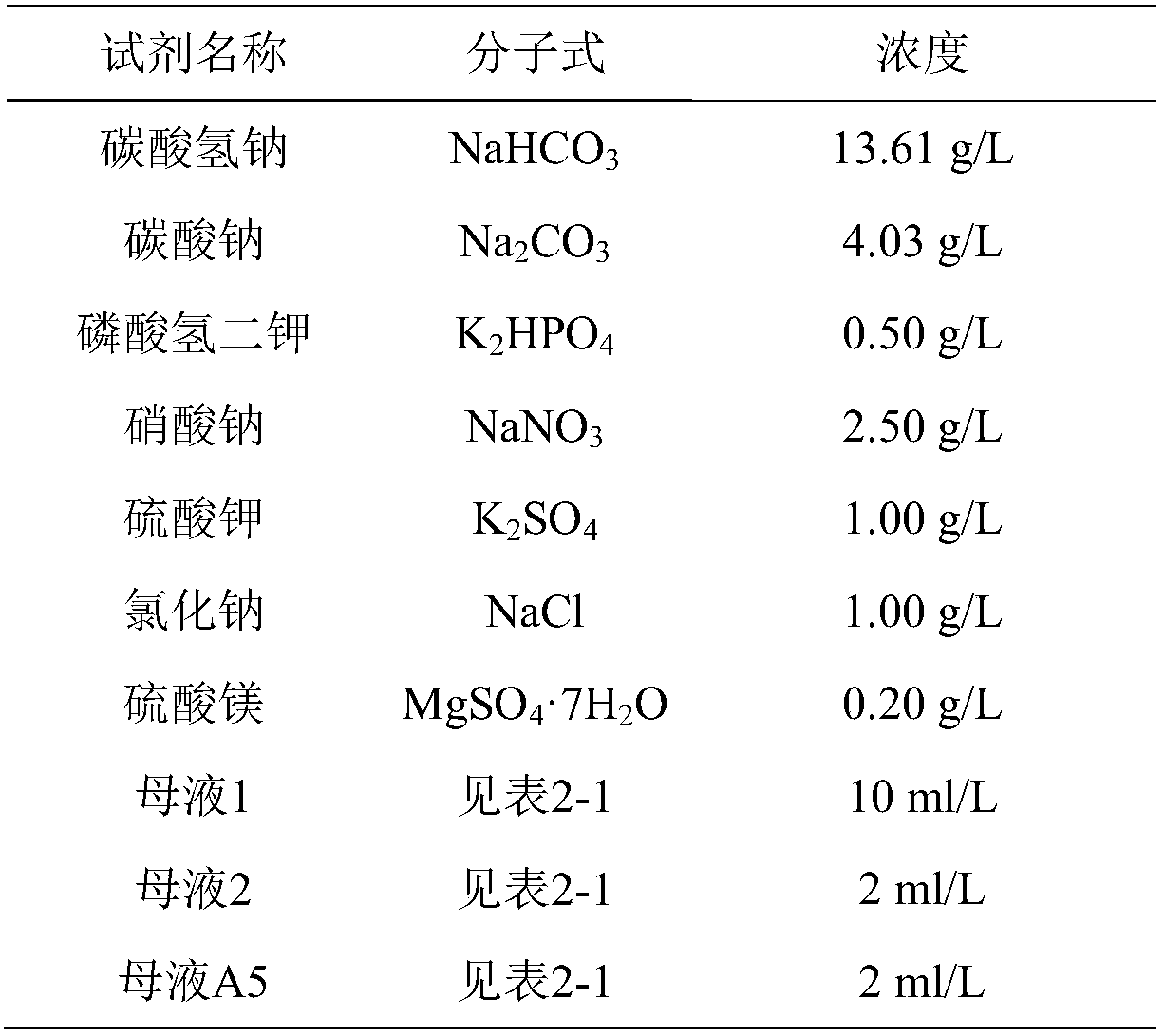

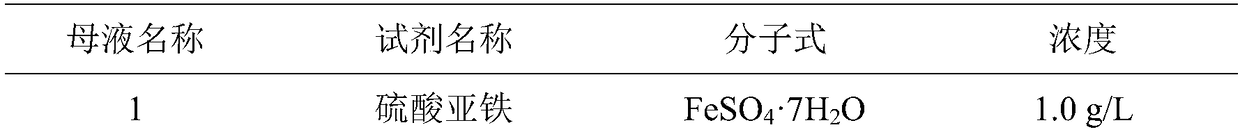

[0119] Wherein, the specific formula of the fresh water medium is Zarrouk med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com