Membrane electrode electrolysis ozone generator and preparation process thereof

An ozone generator and membrane electrode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of difficult membrane electrode area, high material cost, breakdown of cation exchange membrane, etc., to solve the problem of uneven current distribution, The effect of uniform particle distribution and material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

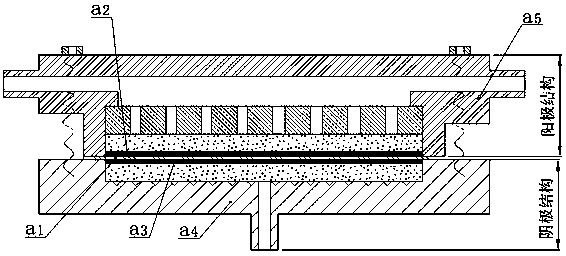

[0067] see Figure 4-Figure 10 , the embodiment of the preparation process of a kind of above-mentioned membrane electrode electrolysis ozone generator of the present invention, comprises the following steps;

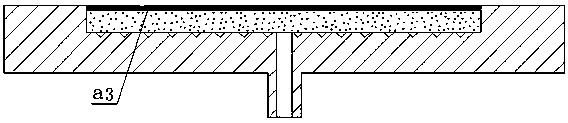

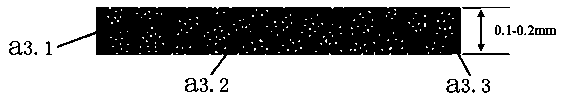

[0068] (1) A sealing ring 4 is arranged on the concave surface of the cathode diversion_fastening plate 3, and a cathode microporous plate 2 is arranged in the sealing ring 4, and the Ti 2 o 3 Particle 1-a or the Ti 2 o 3 The mixture of particle 1.1 and separator particle 1.2 is filled on the cathode microporous plate 2 in the sealing ring 4, and the accumulated Ti 2 o 3 Granules 1.1 or Ti 2 o 3 The particles 1.1 and the separated particle mixture 1.2 are scraped to form a cathode catalyst particle layer 1, which is flush with the top surface of the sealing ring 4 (such as Figure 7 shown);

[0069] (2) Under the parallel downward pressure of the press, make the cathode catalyst particle layer 1 pressure to 100-200N / cm 2 , forming a layer of cathode catalyst pa...

Embodiment 1

[0074]Cathode structure preparation: set the sealing ring 4 on the cathode diversion_fastening plate 3, and set the cathode inside the sealing ring 4 (φ39 mm (outer diameter) × φ34 mm (inner diameter) × 3 mm (thick)) made of fluorine rubber The outer diameter of the microporous plate 2 and the cathode microporous plate 2 (such as a titanium microporous plate) are equal to the inner diameter of the sealing ring 4 . 180 purpose Ti 2 o 3 Particles 1.1 are filled into the sealing ring 4, scraped and leveled with the sealing ring 4 ( Figure 7 ). Under the parallel downward pressure of the press ( Figure 8 ), so that the pressure of the cathode catalyst particle layer 1 reaches 100-200N / cm 2 , the cathode catalyst particle layer 1 is basically formed. The cathode microporous plate 2 is a titanium microporous plate, and the pores of the titanium microporous plate are 40-80 μm.

[0075] Then, the cation exchange membrane 5 (such as: DuPont Nafion @ 117 film) be spread on the ...

Embodiment 2

[0078] Cathode structure preparation: set the sealing ring 4 on the cathode diversion_fastening plate 3, and set the cathode inside the sealing ring 4 (φ39 mm (outer diameter) × φ34 mm (inner diameter) × 3 mm (thick)) made of fluorine rubber The outer diameter of the microporous plate 2 and the cathode microorifice plate 2 are equal to the inner diameter of the sealing ring 4 . 180 purpose Ti 2 o 3 Granules 1.1 and 180-mesh polytetrafluoroethylene particles 1.2 are mixed evenly at a ratio of 100:5, then filled into the sealing ring 4, scraped and leveled with the sealing ring 4 ( Figure 7 ). Under the parallel downward pressure of the press ( Figure 8 ), so that the pressure of the cathode catalyst particle layer 1 reaches 100-200N / cm 2 , the cathode catalyst particle layer 1 is basically formed. The cathode microporous plate 2 is a titanium microporous plate, and the pores of the titanium microporous plate are 40-80 μm.

[0079] Then, put a cation exchange membrane 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com