Method for processing semi-shading sunshade fabric

A processing method and sunshade technology, applied in the field of fabric processing, can solve the problems of insufficient fabric strength, stiffness and flatness, and achieve the effects of strong sunlight fastness, improved stability, and high breaking resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

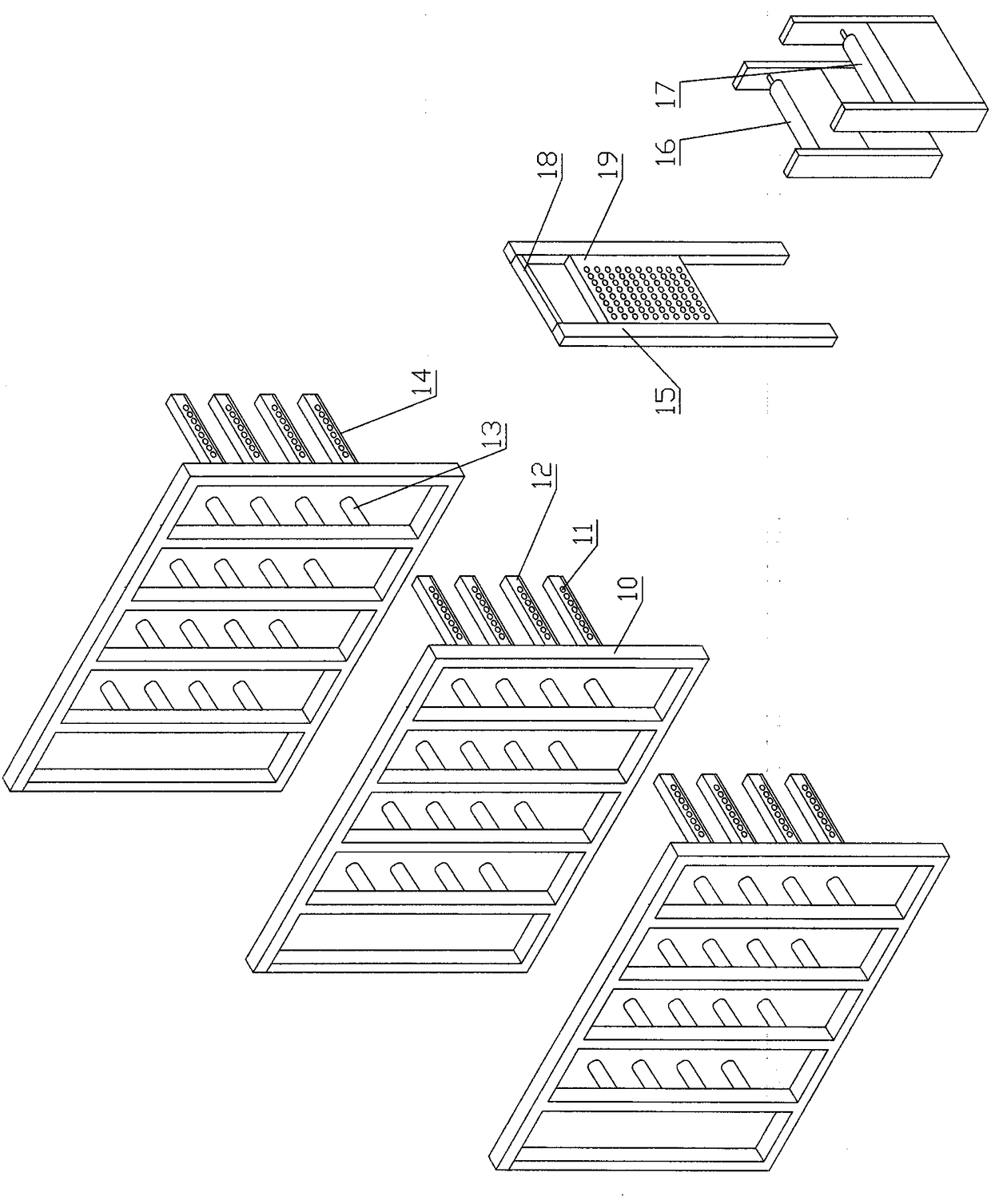

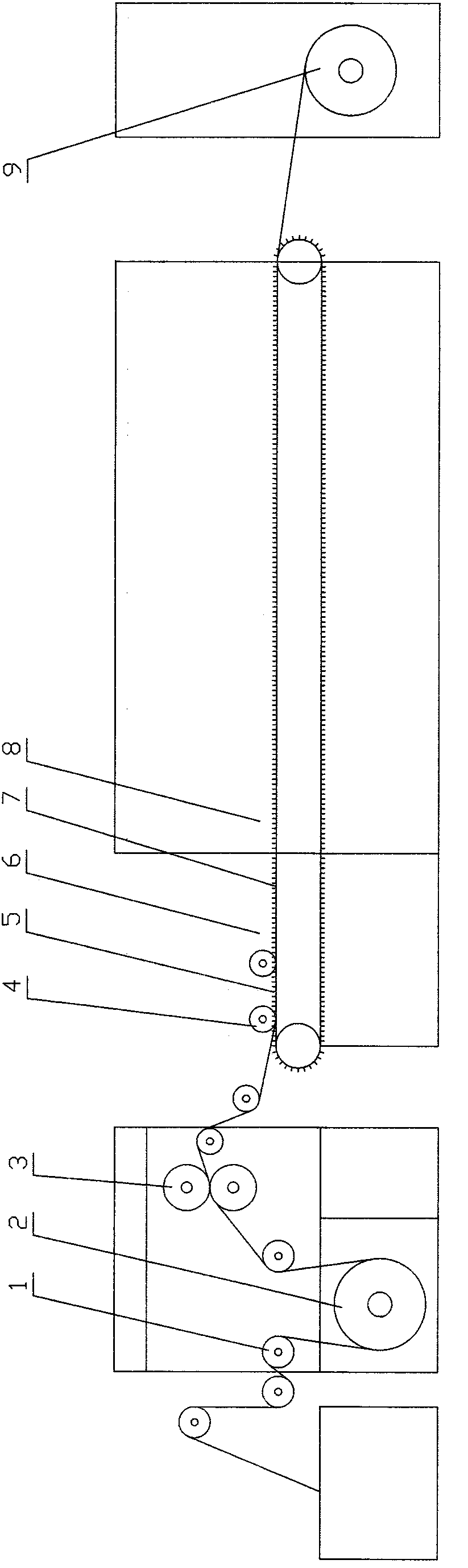

[0015] The relevant details of the present invention will be further described below in conjunction with the accompanying drawings. Referring to the accompanying drawings, the processing method of this kind of semi-shading sunshade fabric is characterized by the following steps:

[0016] 1) A fully automatic warping machine is used for warping, and the warp and weft yarns are all made of polyester low elastic yarn. The warping machine includes a wire bobbin frame 10, a wire frame 15, a warp beam 17 and a drive shaft 16, and the wire bobbins are arranged on the wire bobbin frame in turn, and the wire bobbin frame 10 is provided with several layers, and each layer is arranged with several The wire spool shaft 13, each layer is provided with a wire collecting plate 12, the wire collecting plate is provided with a row of yarn guide holes 11 identical to the number of the layer of wire spool shafts, and a sensor 14 is installed on the wire collecting plate, the wire collecting fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com