Dyeing technology for polyester woven tape with high color fastness

A polyester webbing, color fastness technology, applied in the direction of dyeing method, textile and papermaking, improved hand-feeling fibers, etc., can solve the problems of low color fastness, general dyeing effect of polyester webbing, etc., achieve high dyeing percentage, reduce usage Condition and dyeing cost, effect of good moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

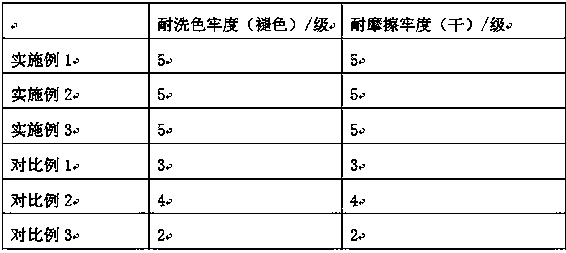

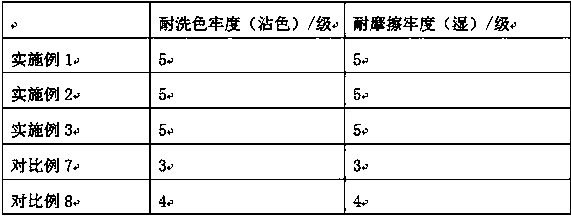

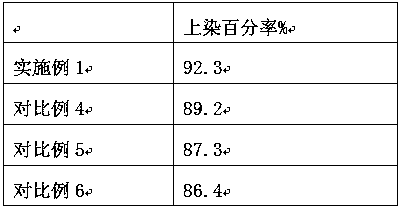

Embodiment 1

[0017] The invention discloses a dyeing process of polyester webbing with high color fastness. The polyester webbing is modified to obtain a modified polyester webbing, and the modified polyester webbing is dyed with a scutellaria dye, then taken out, and dried in a ventilated place.

[0018] Further, the preparation method of the modified polyester webbing is as follows: mix the polyester webbing with deionized water at a ratio of 100g:400mL, heat to 65°C, then add 10% lignin by the mass of the polyester webbing, stir evenly, and then add Organic acid with quality such as lignin, after stirring evenly, adjust the temperature to 80°C, stir at 120r / min for 1 hour, then add cross-linking agent with 0.15% of lignin mass, continue to keep warm and stir for 2 hours, then filter, use Wash the filtered polyester webbing with deionized water to neutrality, and dry it to constant weight to obtain the modified polyester webbing.

[0019] Further, the crosslinking agent is formaldehyde. ...

Embodiment 2

[0028] The invention discloses a dyeing process of polyester webbing with high color fastness. The polyester webbing is modified to obtain a modified polyester webbing, and the modified polyester webbing is dyed with a scutellaria dye, then taken out, and dried in a ventilated place.

[0029] Further, the preparation method of the modified polyester webbing is as follows: mix the polyester webbing with deionized water at a ratio of 120g:400mL, heat to 65°C, then add 10% lignin by the mass of the polyester webbing, stir evenly, and then add Organic acid with quality such as lignin, after stirring evenly, adjust the temperature to 80°C, stir at 120r / min for 1 hour, then add cross-linking agent with 0.15% of lignin mass, continue to keep warm and stir for 2 hours, then filter, use Wash the filtered polyester webbing with deionized water to neutrality, and dry it to constant weight to obtain the modified polyester webbing.

[0030] Further, the crosslinking agent is formaldehyde. ...

Embodiment 3

[0039] The invention discloses a dyeing process of polyester webbing with high color fastness. The polyester webbing is modified to obtain a modified polyester webbing, and the modified polyester webbing is dyed with a scutellaria dye, then taken out, and dried in a ventilated place.

[0040] Further, the preparation method of the modified polyester webbing is as follows: mix the polyester webbing with deionized water at a ratio of 110g:400mL, heat to 65°C, then add 10% lignin by the mass of the polyester webbing, stir evenly, and then add Organic acid with quality such as lignin, after stirring evenly, adjust the temperature to 80°C, stir at 120r / min for 1 hour, then add cross-linking agent with 0.15% of lignin mass, continue to keep warm and stir for 2 hours, then filter, use Wash the filtered polyester webbing with deionized water to neutrality, and dry it to constant weight to obtain the modified polyester webbing.

[0041] Further, the crosslinking agent is formaldehyde. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com