Gastrodia elata drying technology, gastrodia elata powder preparation technology and freeze-dried gastrodia elata and gastrodia elata powder obtained through gastrodia elata drying technology and gastrodia elata powder preparation technology

A drying process and a preparation process technology, applied in the field of traditional Chinese medicine preparation, can solve the problems affecting the appearance of gastrodia elata, such as gastrodin content, etc., and achieve the effects of high quality appearance, uniform particle size and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] The preparation process of gastrodia elata powder provided by the present invention is to obtain gastrodia elata powder after the freeze-dried gastrodia elata obtained by the above-mentioned gastrodia elata drying process is ultrafinely pulverized. The preparation process of the gastrodia elata powder has the same advantages as the above-mentioned gastrodia elata drying process, and also has the advantages of simple operation. , Gastrodia elata powder has the advantage of uniform particle size after crushing.

[0089] In a preferred embodiment, the process parameters of superfine pulverization include: the material temperature is 2-20°C, the pulverization time is 3-15min, and the particle size of Gastrodia elata after superfine pulverization is 200-500 mesh;

[0090] Typical but non-limiting examples of material temperature are 2°C, 3°C, 4°C, 5°C, 6°C, 7°C, 8°C, 9°C, 10°C, 11°C, 12°C, 13°C, 14°C, 15°C ℃, 16℃, 17℃, 18℃, 19℃ or 20℃;

[0091] Typical but non-limiting exam...

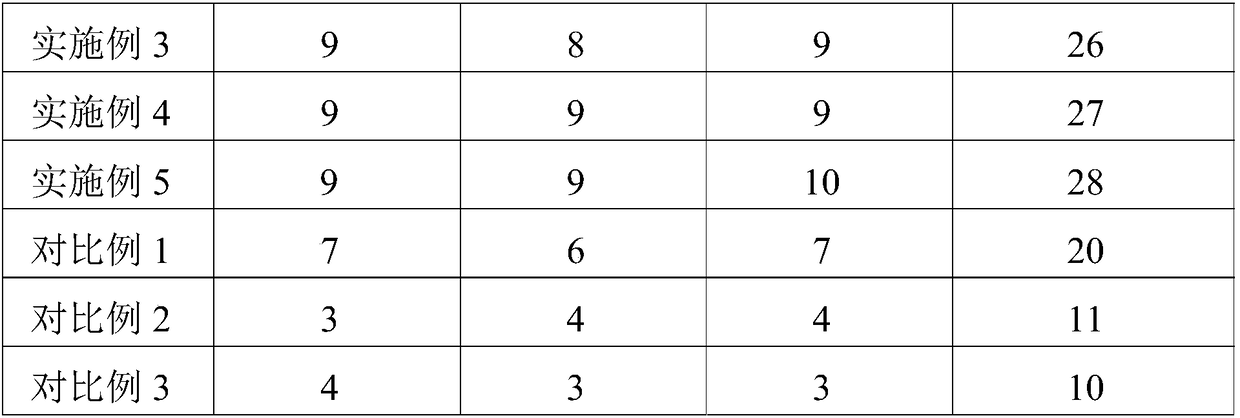

Embodiment 1

[0118] A preparation process of Gastrodia elata powder, comprising the following steps:

[0119] (1) Select fresh Gastrodia elata, and remove unqualified parts according to quality standards;

[0120] (2) Wash the fresh Gastrodia elata until there are no mud spots;

[0121] (3) Steam the washed Gastrodia elata, the heating temperature is 100°C, and steam until the heart is penetrated;

[0122] (4) Slicing the steamed gastrodia elata through the heart, the slice thickness is 10mm;

[0123] (5) Evenly spread the steamed and sliced Gastrodia elata on the tray trolley on the track. After placement, transfer the tray trolley along the track to the quick-freezing warehouse, close the quick-freezing warehouse, and the freezing temperature is -35°C. ℃, frozen to the heart;

[0124] (6) Transfer the frozen Gastrodia elata to the drying bin, turn on the vacuum unit and the refrigeration unit for vacuum drying, and the drying includes the first drying stage, the second drying stage ...

Embodiment 2

[0133] A preparation process of Gastrodia elata powder, comprising the following steps:

[0134] (1) Select fresh Gastrodia elata, and remove unqualified parts according to quality standards;

[0135] (2) Wash the fresh Gastrodia elata until there are no mud spots;

[0136] (3) Steam the washed Gastrodia elata, the heating temperature is 110°C, and steam until the heart is penetrated;

[0137] (4) Slicing the steamed gastrodia elata, the slice thickness is 2mm;

[0138] (5) Evenly spread the steamed and sliced Gastrodia elata on the tray trolley on the track. After placement, transfer the tray trolley along the track to the quick-freezing warehouse, close the quick-freezing warehouse, and the freezing temperature is -50 ℃, frozen to the heart;

[0139] (6) Transfer the frozen Gastrodia elata to the drying bin, turn on the vacuum unit and the refrigeration unit for vacuum drying, and the drying includes the first drying stage, the second drying stage and the third drying s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com