A kind of hot forming and quenching integrated forming method

A hot forming and hot pressing forming technology, applied in the field of precision sheet metal processing, can solve the problems of material deformation, long cycle time, high energy consumption, etc., and achieve the effects of low cost, less tooling, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The thickness of the 2A12 hard aluminum alloy plate used in this example is 2mm, the lower end surface of the deep-drawn part is 70mm×70mm, the accuracy requirement is ±0.2mm, the height is 15mm, the upper end surface is 10mm long, and the center line of the fillet is R3. The accuracy requirements are ±0.1mm.

[0063] Specifically, proceed as follows:

[0064] (1) Plane unfolding: According to the relative position of the aluminum alloy plate, the thickness of the plate required for hot press forming is designed to be 2mm, and the plate size is 114mm×70mm. Grind and pickle the board and apply lubricant.

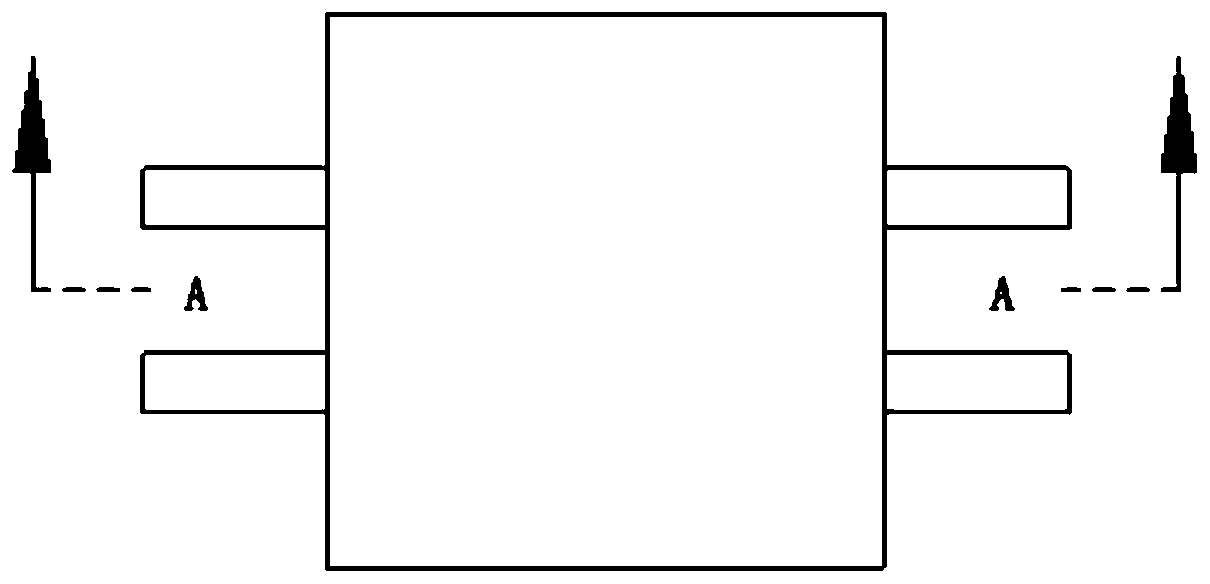

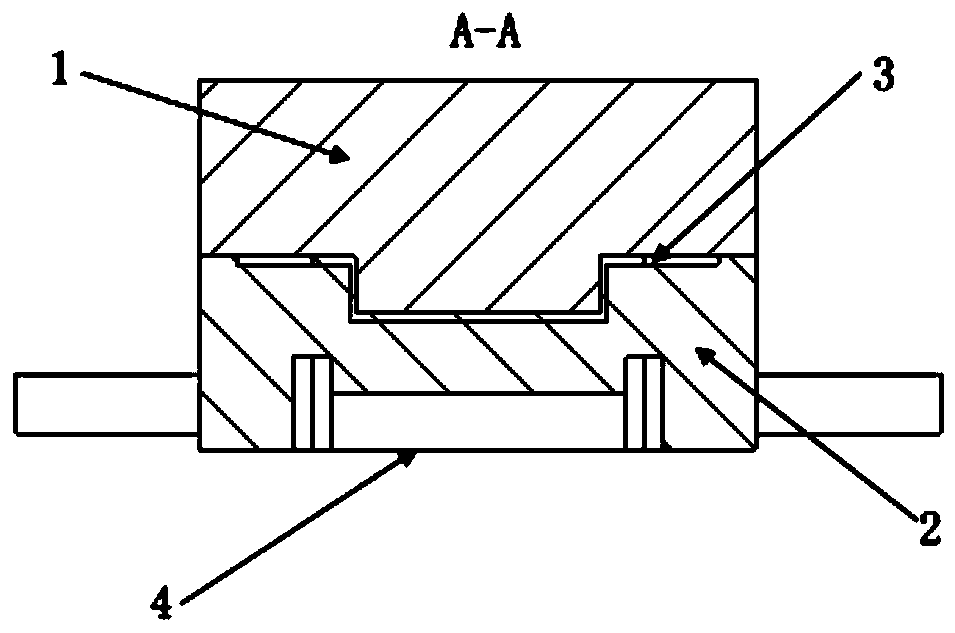

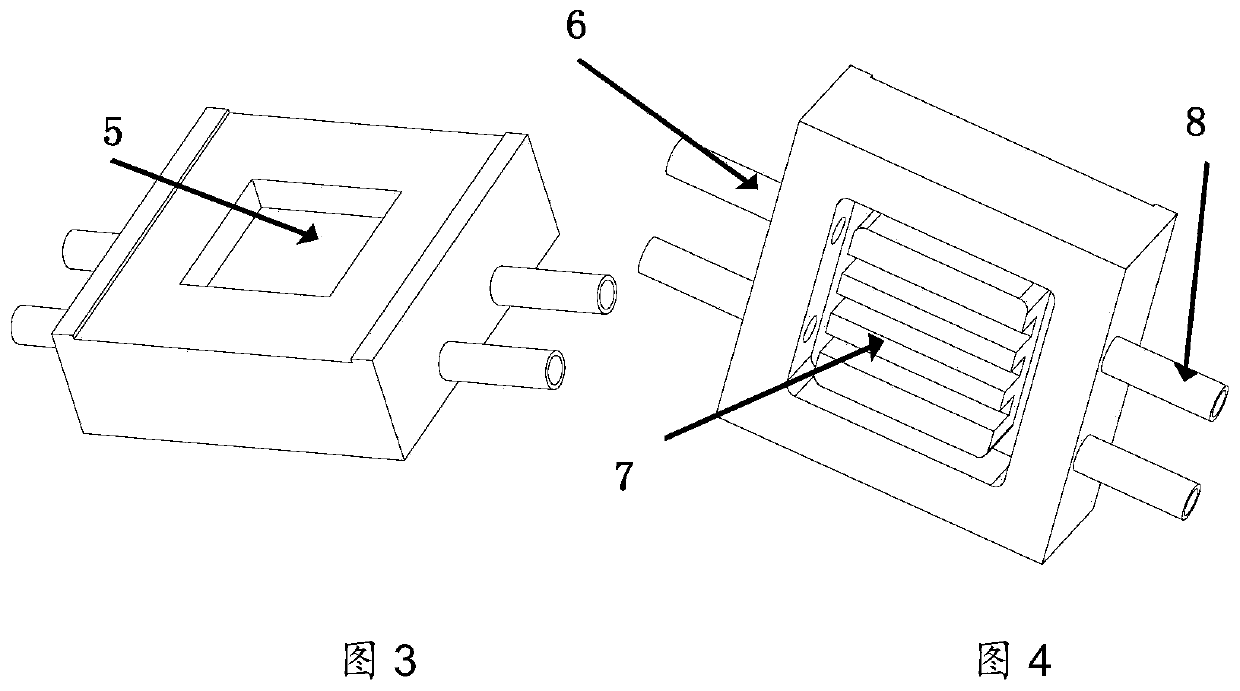

[0065] (2) Designing the forming die: When designing and manufacturing the hot-pressing forming die for the aluminum alloy plate, it is necessary to enlarge the processing according to the final size of the aluminum alloy plate part, and the enlargement factor is selected as 5‰. Design the diameter of the water inlet pipe and outlet pipe of the cooling device on the ...

Embodiment 2

[0071] The thickness of the 2A12 hard aluminum alloy plate used in this example is 2mm, the lower end surface of the deep-drawn part is 70mm×70mm, the accuracy requirement is ±0.2mm, the height is 15mm, the upper end surface is 10mm long, and the center line of the fillet is R3. The accuracy requirements are ±0.1mm.

[0072] Specifically, proceed as follows:

[0073] (1) Plane unfolding: According to the relative position of the aluminum alloy plate, the thickness of the plate required for hot press forming is designed to be 2mm, and the plate size is 114mm×70mm. Grind and pickle the board and apply lubricant.

[0074] (2) Designing the forming die: When designing and manufacturing the aluminum alloy plate hot-pressing forming die, it is necessary to enlarge the processing according to the final size of the aluminum alloy plate part, and the amplification factor is selected as 3‰. Design the diameter of the water inlet pipe and outlet pipe of the cooling device on the lower ...

Embodiment 3

[0080] The thickness of the 2A12 hard aluminum alloy plate used in this example is 2mm, the lower end surface of the deep-drawn part is 70mm×70mm, the accuracy requirement is ±0.2mm, the height is 15mm, the upper end surface is 10mm long, and the center line of the fillet is R3. The accuracy requirements are ±0.1mm.

[0081] Specifically, proceed as follows:

[0082] (1) Plane unfolding: According to the relative position of the aluminum alloy plate, the thickness of the plate required for hot press forming is designed to be 2mm, and the plate size is 114mm×70mm. Grind and pickle the board and apply lubricant.

[0083] (2) Designing the forming die: When designing and manufacturing the aluminum alloy plate hot-pressing forming die, it is necessary to enlarge the processing according to the final size of the aluminum alloy plate part, and the amplification factor is selected as 7‰. Design the diameter of the water inlet pipe and outlet pipe of the cooling device on the lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com