Calibration method and device for hand-eye relation of polishing operation arm

A calibration method and a calibration device technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of inapplicability of fast automatic identification, etc., and achieve the effect of solving fast automatic identification and improving the grinding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

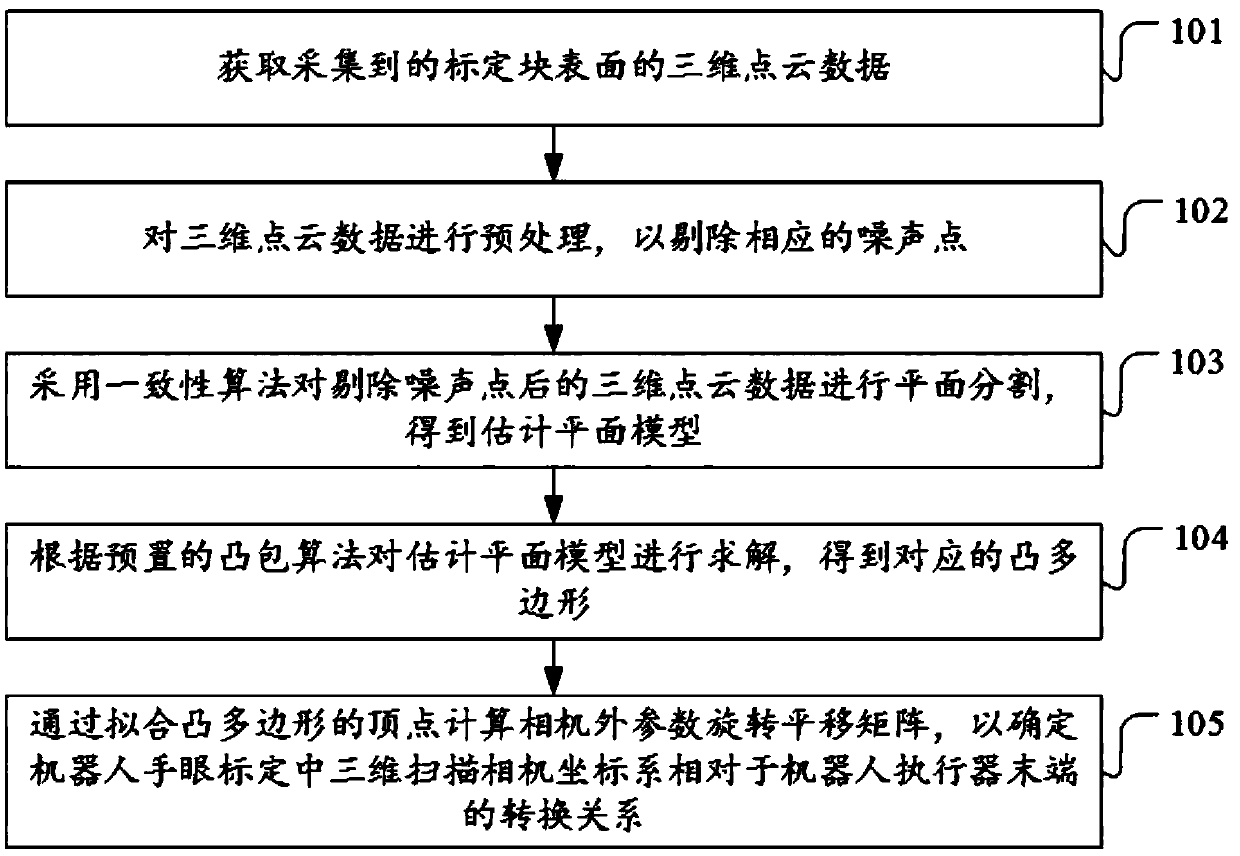

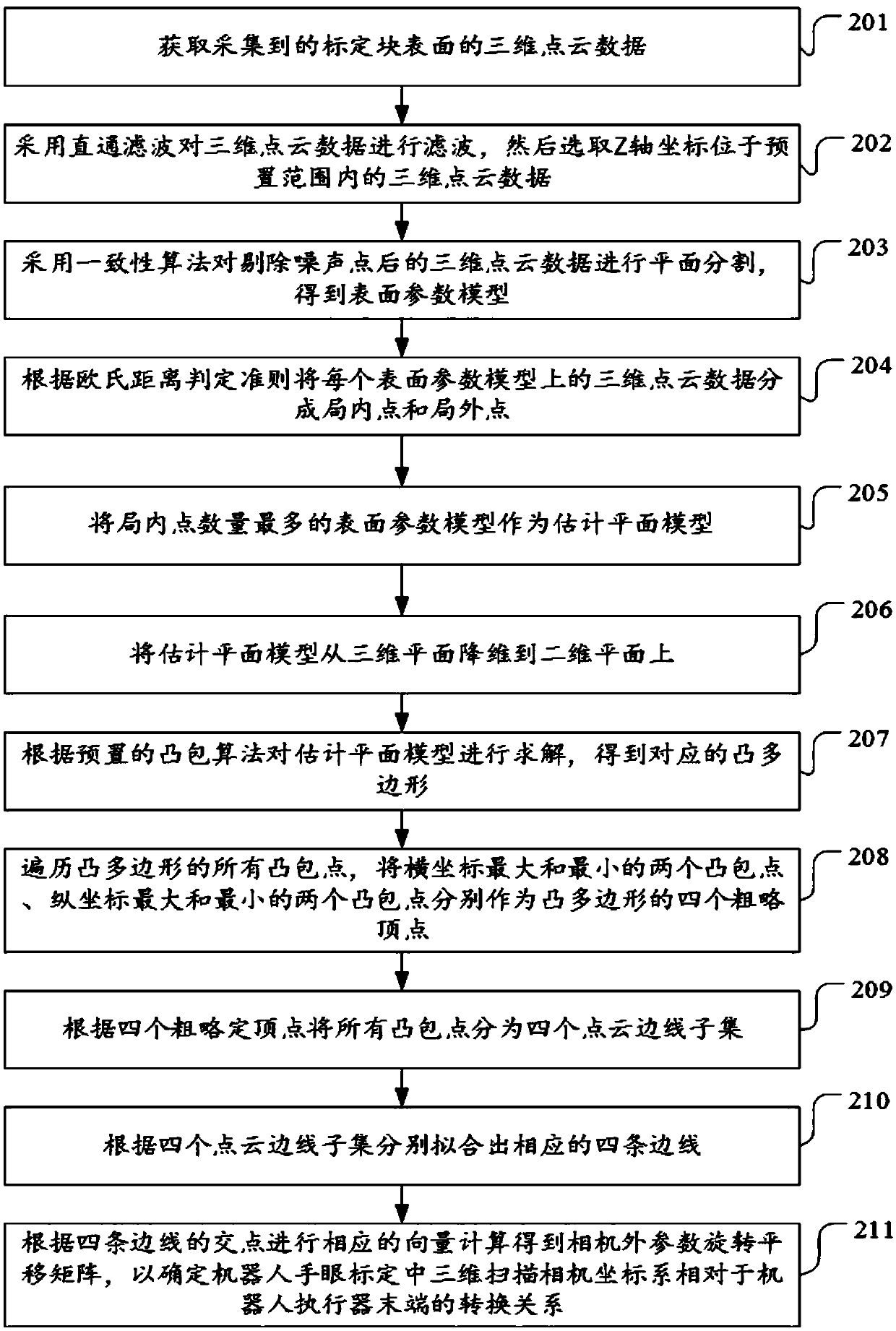

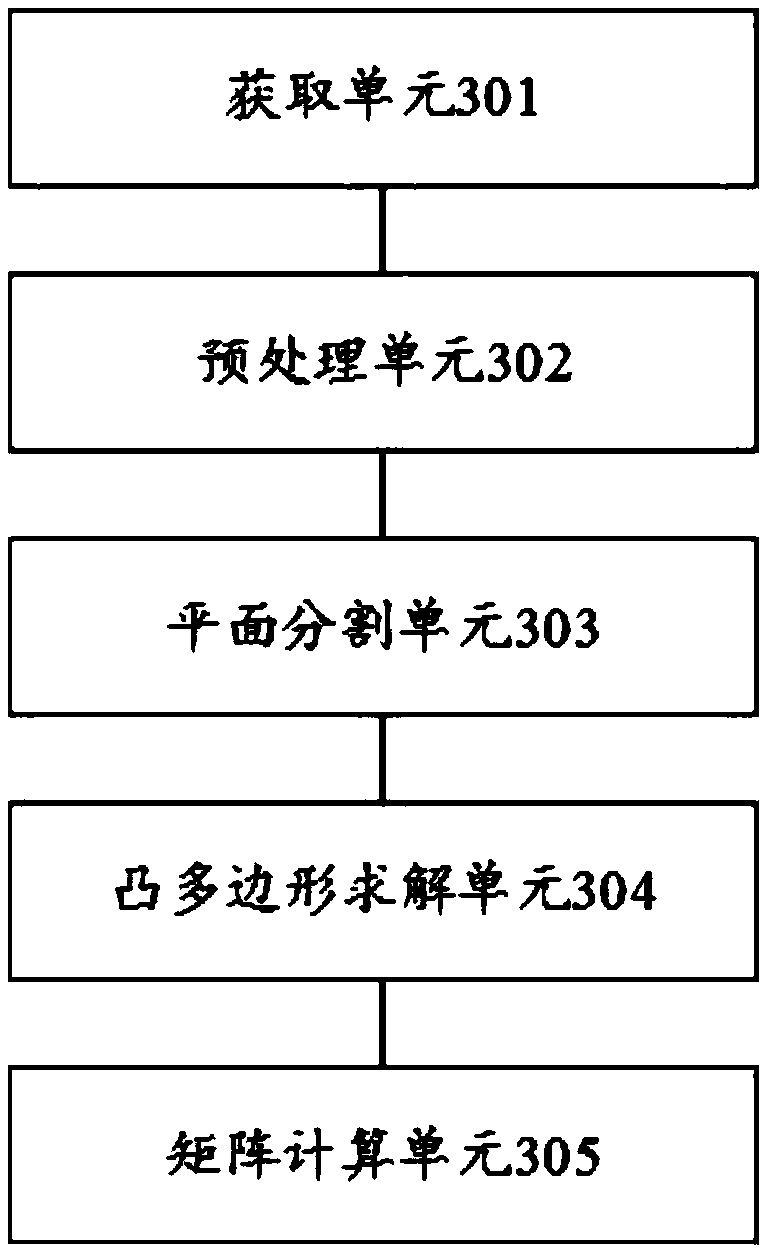

[0059] The embodiments of the present invention provide a method and device for calibrating the hand-eye relationship of a polishing manipulator, which solves the technical problem that the traditional visual sensor 3D stereo calibration is not suitable for the rapid automatic identification required by the polishing system.

[0060] In order to better understand the technical solution of the present invention, it should be noted that:

[0061] Because the 3D stereo calibration of the traditional vision sensor is not suitable for the fast automatic identification required by the grinding system, the hand-eye relationship proposed by Shiu et al. The relationship B is established, AX=XB matrix equation is established, and the transformation relationship matrix X between the vision sensor and the robot end is solved.

[0062] The calibration of the robot 3D scanning system includes the calibration of the internal parameters of the scanner, the conversion relationship between the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com