Modularized construction method of sewage treatment tank

A technology of sewage treatment and construction method, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc. problems, to achieve the effect of a wide range of applications, low construction costs, and convenient dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 A kind of modular construction method of sewage treatment pool

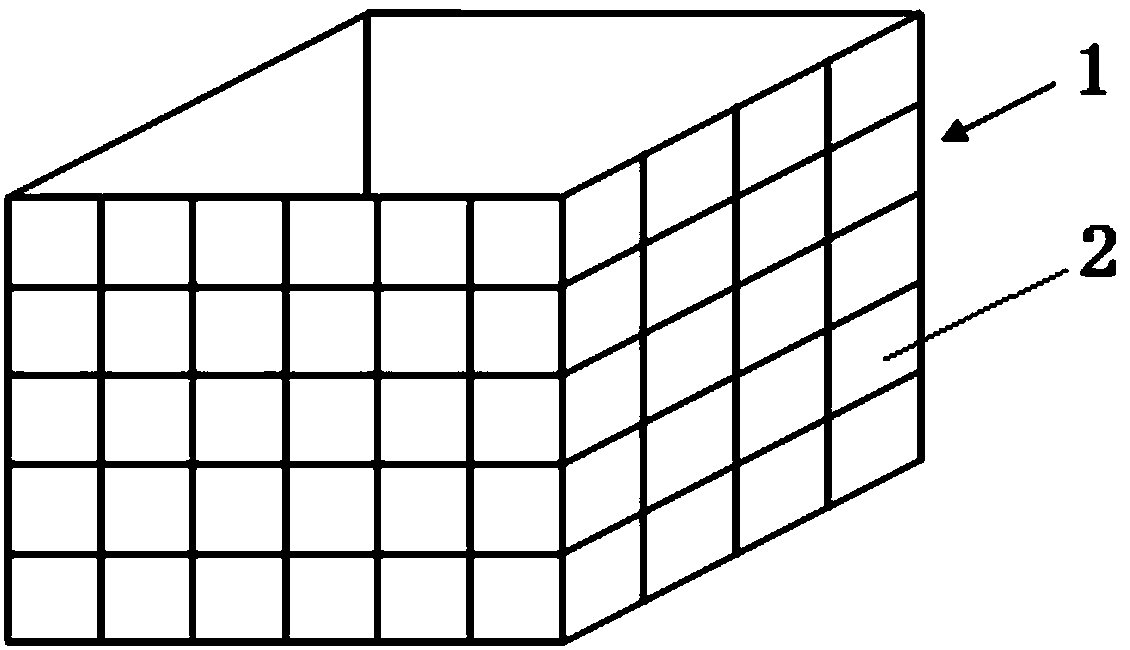

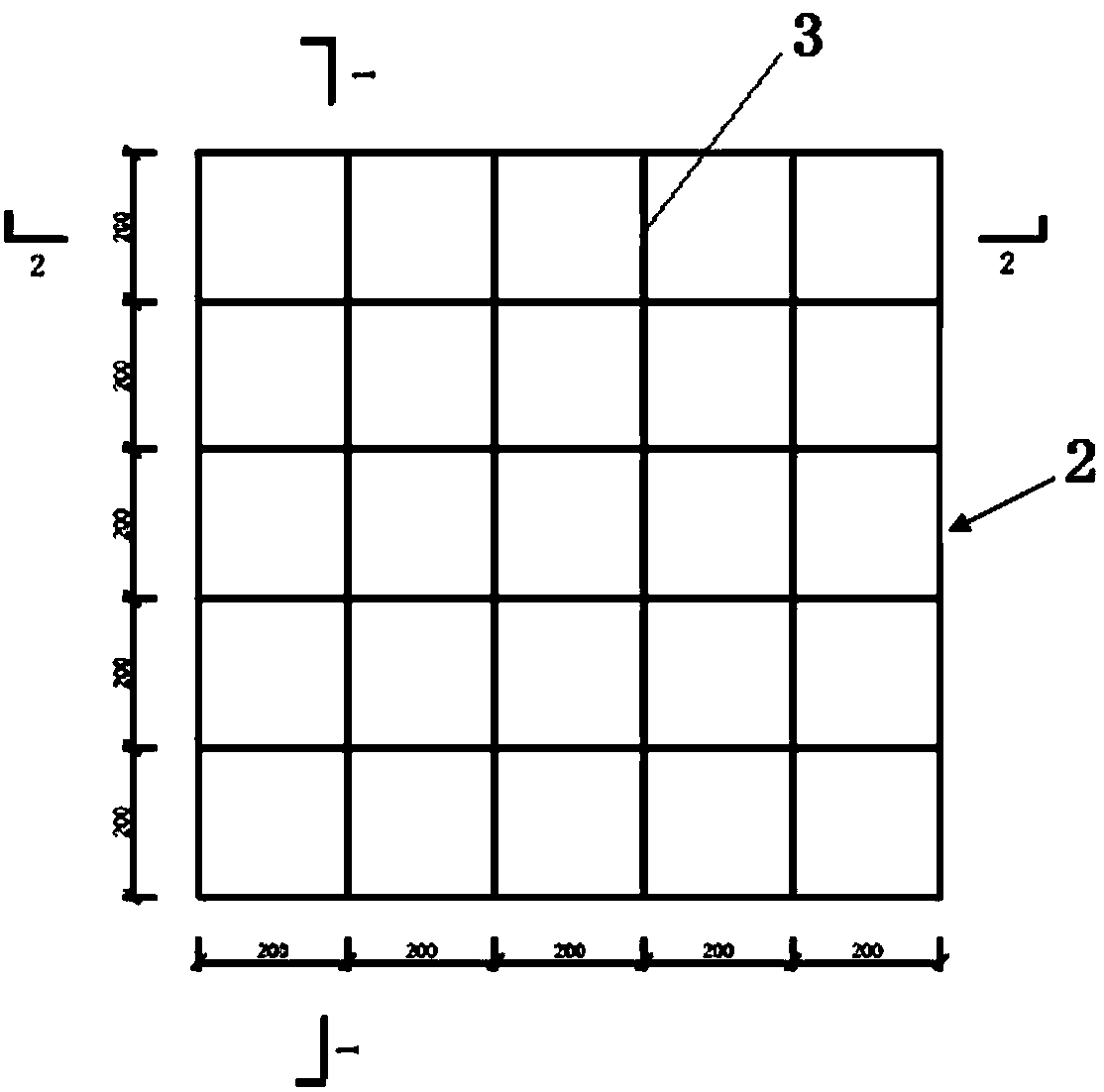

[0033] (1) According to the specifications of the sewage treatment pool 1, the module 2 of the pool is made, and the thickness and compressive strength of the module 2 correspond to the specifications of the sewage treatment pool 1; The 3D printer prints directly, the production speed is fast, and the quality is guaranteed. The module 2 is made of waste plastics, the module 2 is provided with reinforcing ribs 3, the reinforcing ribs 3 are arranged in a grid of round steel 6, and the surface of the module 2 corresponds to the positions of the reinforcing ribs 3. There are reinforcing parts 7.

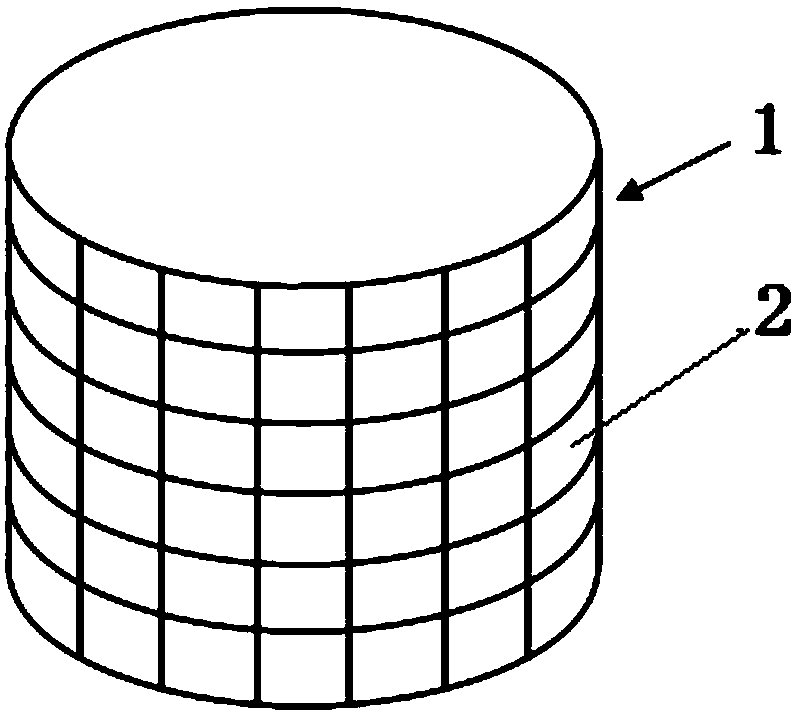

[0034] The selection of module 2 specifications mainly depends on the specifications of sewage treatment pool 1, and the specifications of conventional sewage treatment pool 1 mainly have a square shape (such as figure 1 ), cylindrical (such as figure 2 ), and the corresponding modules include planar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com