A lithium battery waste liquid treatment device and treatment method

A technology of waste liquid treatment and lithium battery, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

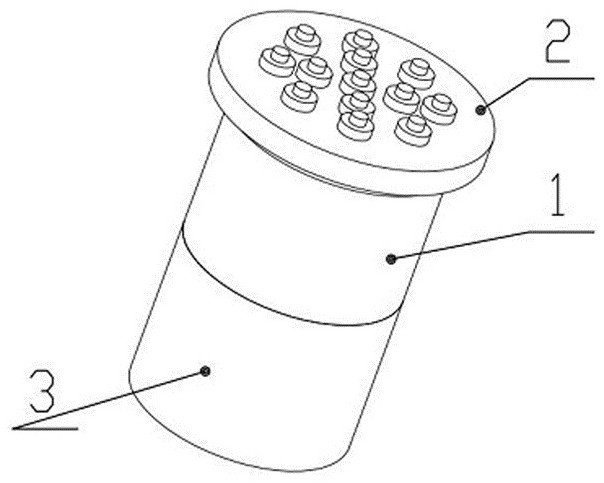

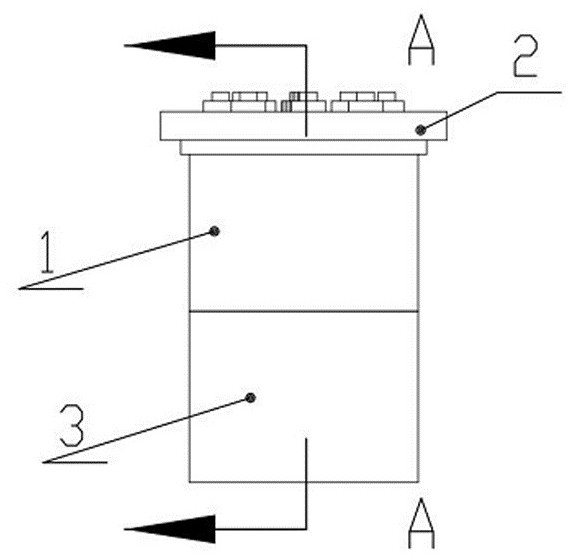

[0032] see figure 1 , is a lithium battery waste liquid treatment device provided in an embodiment of the present invention, which is characterized in that it includes: a waste liquid treatment body 1, a waste liquid treatment support seat 2, and a liquid collection tank 3, the waste liquid treatment body 1, the waste liquid treatment body Both the waste liquid treatment support seat 2 and the liquid collection tank 3 are in the shape of a cylinder, the waste liquid treatment support seat 2 is arranged on the top of the waste liquid treatment body 1, and the liquid collection box 3 is arranged on the The bottom of the waste liquid treatment body 1 .

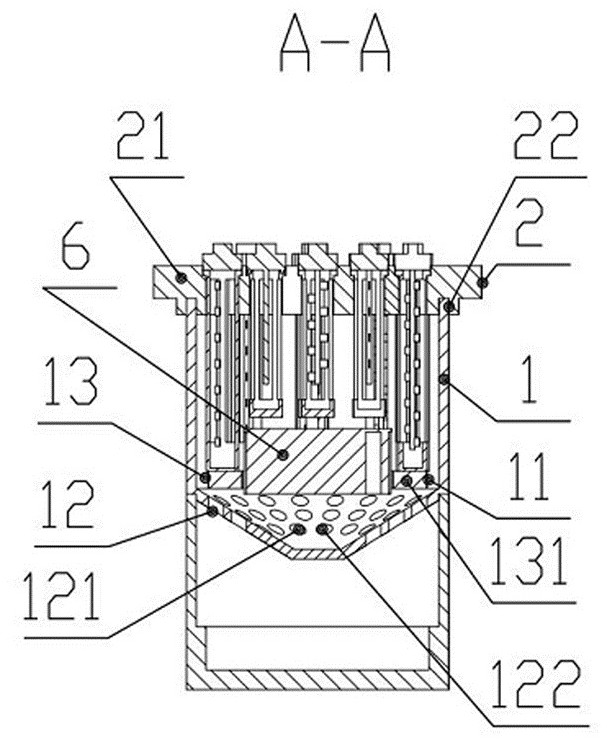

[0033] Among them, see figure 2 and image 3 , is a schematic structural diagram of a lithium battery waste liquid treatment device provided in an embodiment of the present invention, the waste liquid treatment body 1 is provided with a waste liquid treatment column accommodation cavity 11, and the waste liquid treatment suppo...

Embodiment 2

[0039] see image 3 , is an A-A cross-sectional view of a lithium battery waste liquid treatment device provided by the embodiment of the present invention. The difference between the embodiment of the present invention and the first embodiment is that the bottom of the waste liquid treatment body 1 in the embodiment of the present invention is provided with Aeration device 6, the aeration device 6 is in the shape of a cylinder, the diameter of the aeration device 6 is smaller than the diameter of the accommodating chamber 11 of the waste liquid treatment column, and the embodiment of the present invention is the same as the first embodiment Refer to Embodiment 1, which will not be repeated here. Adding the aeration device 6 can cause a large number of small bubbles to be formed inside the waste liquid, and the small bubbles can carry harmful substance particles to move to the top of the liquid surface, so that the valves 131 can be opened to flow into the waste liquid. The ha...

Embodiment 3

[0041] see Figure 5 , is a schematic diagram of the front structure and a schematic diagram of the reverse structure of the waste liquid treatment support seat of the lithium battery waste liquid treatment device provided by the embodiment of the present invention. The difference between the embodiment of the present invention and the first embodiment is that the stirring rod in the embodiment of the present invention There are multiple accommodating stepped holes 23, and the accommodating stepped holes 23 for the stirring rod are evenly distributed in a circumferential shape on the upper surface of the waste liquid treatment support base 2. Referring to Embodiment 1, details will not be repeated here. In this way, multiple waste liquid treatment columns 4 can be arranged and evenly distributed to improve the removal efficiency of harmful substances in waste liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com