White polyimide film and preparation method thereof

A polyimide film and white technology, which is applied in the field of white polyimide film and its preparation, can solve the problems of poor mechanical strength and poor stability of polyimide film, and achieve good mechanical strength and good stability , good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

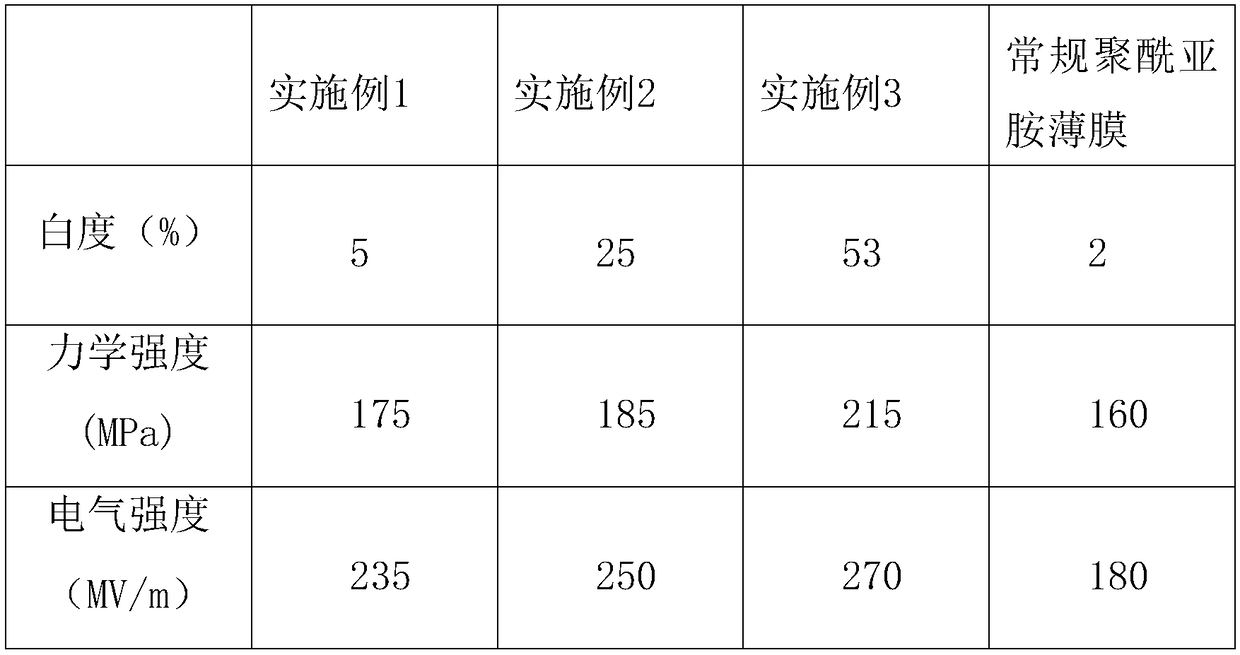

Examples

Embodiment 1

[0015] Step 1: According to the mass percentage, add 80.07% of dimethylacetamide and 9.5% of diaminodiphenyl ether into the reactor, stir for 45 minutes, then add 10.4% of pyromellitic dianhydride into the reactor, and stir After 45 minutes, finally add 0.03% of nano-titanium dioxide into the reaction kettle, stir for 45 minutes, and prepare glue after the stirring is completed;

[0016] Step 2: The glue solution prepared in step 1 is salivated onto the surface of the mirror steel belt of the casting machine through the spraying die, and the glue solution is prepared into a gel film by the casting machine under the condition of 130°C;

[0017] Step 3: Peel off the gel film from the surface of the mirror steel belt of the casting machine. Under the condition of 400°C, use a longitudinal stretching machine to stretch the gel film longitudinally. The stretching ratio of the longitudinal stretching is 1.2 , and then use a transverse stretching machine to transversely stretch the g...

Embodiment 2

[0019] Step 1: According to the mass percentage, add 80% of dimethylacetamide and 9.5% of diaminodiphenyl ether into the reactor, stir for 30 minutes, then add 10.4 pyromellitic dianhydride into the reactor, and stir for 40 minutes Finally, add 0.10% nano-titanium dioxide into the reaction kettle, stir for 30 minutes, and prepare the glue after the stirring is completed;

[0020] Step 2: The glue solution prepared in step 1 is salivated onto the surface of the mirror steel belt of the casting machine through the spraying die, and the glue solution is prepared into a gel film by the casting machine under the condition of 120°C;

[0021] Step 3: Peel off the gel film from the surface of the mirror steel belt of the casting machine. Under the condition of 410°C, use a longitudinal stretching machine to stretch the gel film longitudinally. The stretching ratio of the longitudinal stretching is 1.2 , and then use a transverse stretching machine to transversely stretch the gel film,...

Embodiment 3

[0023] As a preference, the invention discloses a white polyimide film, which is composed of the following components according to mass percentage: 10.4% of pyromellitic dianhydride, 9.5% of diaminodiphenyl ether, and 79.95% of dimethylacetamide , Nano titanium dioxide 0.15%.

[0024] Step 1: According to the mass percentage, add 79.95% of dimethylacetamide and 9.5% of diaminodiphenyl ether into the reactor, stir for 50 minutes, then add 10.4% of pyromellitic dianhydride into the reactor, and stir After 35 minutes, finally add 0.15% of nano-titanium dioxide into the reaction kettle, stir for 45 minutes, and prepare glue after the stirring is completed;

[0025] Step 2: The glue solution prepared in step 1 is salivated onto the surface of the mirror steel belt of the casting machine through the spraying die, and the glue solution is prepared into a gel film by the casting machine under the condition of 120°C;

[0026] Step 3: Peel off the gel film from the surface of the mirro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com